Podcast

Questions and Answers

In a lathe machine, what action is primarily used to cut and shape metal?

In a lathe machine, what action is primarily used to cut and shape metal?

- Revolving the work against a cutting tool (correct)

- Melting the metal to reshape it

- Hammering the metal into the desired shape

- Pressing the metal against a stationary tool

When viewed from the tail stock end, in which direction does the chuck rotate during turning?

When viewed from the tail stock end, in which direction does the chuck rotate during turning?

- Alternating directions

- It does not rotate, it remains stationary

- Clockwise

- Counter-clockwise (correct)

Which principal part of a lathe is essential for carrying all machine parts and resisting cutting forces?

Which principal part of a lathe is essential for carrying all machine parts and resisting cutting forces?

- Bed (correct)

- Tailstock

- Headstock

- Carriage

What component is housed within the headstock of a lathe?

What component is housed within the headstock of a lathe?

What is the primary function of the tail stock?

What is the primary function of the tail stock?

Which part of the carriage assembly allows movement perpendicular to the spindle axis for facing operations?

Which part of the carriage assembly allows movement perpendicular to the spindle axis for facing operations?

What is achieved by swiveling the compound rest on the cross slide?

What is achieved by swiveling the compound rest on the cross slide?

What is the purpose of the leadscrew on a lathe?

What is the purpose of the leadscrew on a lathe?

What distinguishes the dead center from the live center when turning between centers?

What distinguishes the dead center from the live center when turning between centers?

What is the primary use of a three jaw chuck?

What is the primary use of a three jaw chuck?

What purpose does a face plate serve in lathe operations?

What purpose does a face plate serve in lathe operations?

What is the function of lathe dogs and driving plates?

What is the function of lathe dogs and driving plates?

Which type of calipers are used with a steel rule to transfer dimensions?

Which type of calipers are used with a steel rule to transfer dimensions?

What is a key advantage of using Vernier calipers over other measuring tools?

What is a key advantage of using Vernier calipers over other measuring tools?

For measuring components requiring very high accuracy, which instrument is typically used?

For measuring components requiring very high accuracy, which instrument is typically used?

What is the definition of 'cutting speed' in the context of lathe operation?

What is the definition of 'cutting speed' in the context of lathe operation?

How is 'feed' defined in the context of lathe operation?

How is 'feed' defined in the context of lathe operation?

What does 'depth of cut' refer to in lathe operations?

What does 'depth of cut' refer to in lathe operations?

What materials are commonly used for general purpose hand cutting tools?

What materials are commonly used for general purpose hand cutting tools?

What are the main alloying elements in 18-4-1 HSS tools?

What are the main alloying elements in 18-4-1 HSS tools?

What is the primary purpose of 'turning' in lathe operations?

What is the primary purpose of 'turning' in lathe operations?

What lathe operation is used to enlarge a hole that has already been drilled?

What lathe operation is used to enlarge a hole that has already been drilled?

What is the purpose of 'facing' in lathe machining?

What is the purpose of 'facing' in lathe machining?

What describes the process of 'taper turning'?

What describes the process of 'taper turning'?

What is the purpose of chamfering the extreme end of a workpiece?

What is the purpose of chamfering the extreme end of a workpiece?

Flashcards

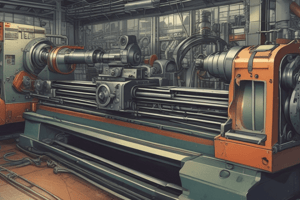

What is a lathe?

What is a lathe?

A machine tool used to cut and shape metal by revolving the work against a cutting tool.

What is the bed of a lathe?

What is the bed of a lathe?

The main body of the lathe, providing a strong and rigid base for all other parts.

What is the headstock?

What is the headstock?

Provides a range of speeds and feeds; contains the main spindle to hold and rotate the work.

What is a tailstock?

What is a tailstock?

Signup and view all the flashcards

What is the carriage or saddle?

What is the carriage or saddle?

Signup and view all the flashcards

What is the compound rest?

What is the compound rest?

Signup and view all the flashcards

What is a tool post?

What is a tool post?

Signup and view all the flashcards

What is the lead screw?

What is the lead screw?

Signup and view all the flashcards

What are centers?

What are centers?

Signup and view all the flashcards

What is a three jaw chuck?

What is a three jaw chuck?

Signup and view all the flashcards

What is a face plate?

What is a face plate?

Signup and view all the flashcards

What are lathe dogs and driving plate?

What are lathe dogs and driving plate?

Signup and view all the flashcards

What are outside and inside calipers?

What are outside and inside calipers?

Signup and view all the flashcards

What is a vernier caliper?

What is a vernier caliper?

Signup and view all the flashcards

What are micrometers?

What are micrometers?

Signup and view all the flashcards

What is cutting speed?

What is cutting speed?

Signup and view all the flashcards

What is "feed" in lathe work?

What is "feed" in lathe work?

Signup and view all the flashcards

What is depth of cut?

What is depth of cut?

Signup and view all the flashcards

What are common tool materials?

What are common tool materials?

Signup and view all the flashcards

What is facing (lathe)?

What is facing (lathe)?

Signup and view all the flashcards

What is turning (lathe)?

What is turning (lathe)?

Signup and view all the flashcards

What is boring (lathe)?

What is boring (lathe)?

Signup and view all the flashcards

What is taper turning?

What is taper turning?

Signup and view all the flashcards

What is Chamfering?

What is Chamfering?

Signup and view all the flashcards

What is threading on a lathe?

What is threading on a lathe?

Signup and view all the flashcards

Study Notes

- Metals are cut to shape using different machine tools in machine shops.

- A lathe cuts and shapes metal by revolving work against a cutting tool.

- Work is clamped in a chuck on the lathe spindle, or between centers.

- The cutting tool is secured in a tool post on a movable carriage.

- The cutting tool can be fed lengthwise or crosswise onto the work.

- When turning, the chuck rotates counter-clockwise when viewed from the tail stock end.

Principal Parts of a Lathe

- A center lathe has main parts that are designed to hold work pieces.

Bed

- The bed is a strong, rigid and essential part of the lathe.

- It carries all machine parts, resists cutting forces, and guides the carriage and tail stock.

- Beds are typically made of cast iron.

Head Stock

- Contains gears or a cone pulley for speed/feed adjustments.

- It contains the main spindle, which holds and rotates the work.

Tail Stock

- The tail stock supports the right-hand end of long work pieces.

- It can be clamped at any bed position.

- The tail stock spindle possesses an internal Morse taper that accepts the dead center.

- Drills, reamers, and taps can be fitted into the spindle for operations.

Carriage / Saddle

- The carriage or saddle controls the cutting tool's movement.

- It includes longitudinal and cross slides plus a compound slide and apron.

- The cross slide allows movement across the bed, perpendicular to the spindle's axis.

- This movement is used for facing and adjusting depth during turning.

- The apron is bolted to the saddle and incorporates controls for the longitudinal and cross slides.

Compound Rest

- The compound rest supports the tool post and can be swiveled on the cross slide to turn short tapers at different angles.

Tool Post

- The tool post secures the tool holder or the cutting tool, adjustable to any working position.

Lead Screw

- A long, threaded shaft positioned in front of the carriage running from head to tail stock.

- Driven from the spindle, it controls the tool's movement for automatic feed or thread cutting.

Centers

- Lathes have two types of centers; dead and live.

- The dead center sits in the tail stock spindle while the live center is in the head-stock spindle.

- When turning between centers, the dead center remains fixed while the live center rotates with the work.

Three Jaw Chuck

- The three jaw chuck is a self-centering work-holding device with three jaws that open and close with respect to the spindle center

- Three jaw chucks are used for holding regular objects like round bars and hexagonal rods.

Face Plate

- Used for turning operations, especially for holding work pieces that cannot be held in chucks.

- Different accessories are used with face plates.

Lathe Dogs and Driving Plate

- Used to drive work pieces held between centers.

- The jaws receive and clamp the work piece, with the dog tail carried by a pin in the driving plate.

Measuring Instruments

- Calipers are used to measure dimensions using steel rules.

- Vernier calipers measure accurately both outside and inside dimensions.

Micrometers

- Micrometers are used for measuring components for greater accuracy

Cutting Parameters

- Cutting speed is the speed at which material is removed, in meters per minute.

- Cutting speed relies on workpiece material, feed, depth of cut, operation type, Spindle speed (RPM) = cutting speed x 1000 / (πD) Where D is the work piece diameter in mm.

- Feed is the distance the tool traverses along the bed per work revolution, based on cut depth and desired surface finish.

- Depth of cut determines movement from the workpiece surface perpendicular to the lathe axis, depending on the operation.

Tool Materials

- Hand cutting tools are made from carbon or tool steel.

- Single point lathe cutting tools are made from high speed steel (HSS), containing 18% tungsten, 4% chromium, and 1% vanadium.

- For better heat resistance, 5-10% cobalt is added to HSS.

- Carbide-tipped tools are typically used in production shops.

Tool Geometry

- A single point cutting tool used on a lathe is a simple wedge.

Lathe Operations

Turning

- Turning produces cylindrical shapes by removing material with a traversing tool from the surface of a rotating work piece. For internal turning internal surfaces are machined in a boring operation, which enlarges a drilled hole.

- For long work, it should be faced, center drilled and supported at one end before being supported by the tail-stock.

Boring

- Boring enlarges a hole, usually done because the correct drill size is not available.

Facing

- Facing creates a flat end surface perpendicular to the axis of rotation.

- The work piece is held in a chuck, rotated, and faced by feeding a cutting tool toward the end of the work piece and perpendicular to the axis of the lathe.

Taper Turning

- A Taper is defined as the uniform change in the diameter of a work piece, measured along its length expressed as the ratio of the difference in diameters to the length.

- Short steep tapers can be made on a lathe by swiveling the compound rest, where the cutting tool is fed with the compound slide feed handle while the work piece rotates in a chuck, face plate, or between centers.

Drilling

- Drilling axially aligns holes in cylindrical parts using a twist drill.

- The work piece rotates in a chuck/face plate, and the drill bit fitted into the tail stock spindle through a chuck.

- The tail stock moves and clamps near the work; while the job rotates, the drill bit feeds into the work using the tail stock hand wheel.

Knurling

- A pattern is embossed on a work piece using a knurling tool.

- The tool presses rollers against the work to create a gripping surface for hand operation.

Chamfering

- Chamfering bevels the extreme end of a work piece for look, to enable nuts to pass freely on threaded parts or to remove damage.

Threading

- Threading cuts helical grooves on a work piece, either internal or external.

- A thread cutting tool is traversed at a specific rate, proportional to the work's revolution speed.

Safety Precautions

- Wear eye protection to prevent hot, sharp metal chips from causing damage.

- Wear short sleeve shirts to avoid loose sleeves catching on rotating parts.

- Wear work shows to protect your feet at the shop floor.

- Remove jewelry and tie back long hair to prevent entanglement.

- Always double check that work is clamped securely before starting the lathe at a low sped.

- After use, remove the chuck key from the chuck immediately.

- Avoid contact of fingers or hands with rotation axes and cutting tools.

- Avoid reaching over spinning chuck to prevent accidents if clothes or materials catch.

- Never use files with a bare tang.

Facing and plain turning

- The aim is to obtain a required diameter of a cylindrical work piece with the given length including tools and equipment such as a lathe, mild steel bar, cutting tool, box/tool post key, chuck key, and calipers.

- Facing finishes the work piece ends to make them flat, smooth, and of required length.

- Rough turning removes stock when surface finish is not critical, using deep cuts with coarse feed.

- During rough machining, there is minimal oversize dimension.

Procedure

- Secure the work piece in the lathe's 3-jaw chuck with a chuck key.

- Secure the right-hand cutting tool with a box key.

- After switching on the machine, swivel the tool post and adjust the cutting point for facing; feed the tool and move the tool post and provide movement by rotating the cross slide's hand wheel

- Once facing is done, swivel the tool post, making the cutting point parallel to the work piece's axis.

- Provide the depth by moving the cross slide and turning the tool post and side hand wheel, rotating to a longitudinal movement for length.

- Inspect the achieved dimensions using either a steel rule, an outside caliper, or a vernier caliper.

Precautions

- Always hold work pieces firmly and avoid over-feeding the tool in rough turning.

- Reduce tool overhang to prevent chatter and rough surfaces.

- Ensure the performance of facing operations runs from center to edge of the part being worked on.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.