Podcast

Questions and Answers

What is the primary function of a Human Machine Interface (HMI)?

What is the primary function of a Human Machine Interface (HMI)?

- To provide a vital link between humans and machines (correct)

- To monitor real-time data only

- To replace PLCs in industrial automation

- To control industrial processes directly

What does DCS stand for?

What does DCS stand for?

- Distributed Control System (correct)

- Digital Control System

- Distributed Computing System

- Data Control System

What is the purpose of programming a PLC?

What is the purpose of programming a PLC?

- To monitor real-time data only

- To control industrial processes directly

- To manage input/output signals and control logic (correct)

- To create graphical interfaces for HMIs

What is the role of an HMI in controlling a process?

What is the role of an HMI in controlling a process?

What is the benefit of using a DCS in a factory?

What is the benefit of using a DCS in a factory?

How do HMIs and PLCs interact?

How do HMIs and PLCs interact?

What is the purpose of a DCS in a factory?

What is the purpose of a DCS in a factory?

What is the advantage of using HMIs in industrial automation?

What is the advantage of using HMIs in industrial automation?

What is the primary function of a DCS in a factory environment?

What is the primary function of a DCS in a factory environment?

What is the purpose of the redundant controller in a DCS?

What is the purpose of the redundant controller in a DCS?

What is the role of the engineering workstation in a DCS control room?

What is the role of the engineering workstation in a DCS control room?

What is the primary function of operator screens in a DCS control room?

What is the primary function of operator screens in a DCS control room?

What is the purpose of OPC devices in a DCS control room?

What is the purpose of OPC devices in a DCS control room?

How many controllers are typically used in each area of a DCS?

How many controllers are typically used in each area of a DCS?

What is the benefit of a DCS in a factory environment?

What is the benefit of a DCS in a factory environment?

What is the purpose of historians in a DCS control room?

What is the purpose of historians in a DCS control room?

What is the main difference between a PLC network and a DCS in terms of setup?

What is the main difference between a PLC network and a DCS in terms of setup?

What is an advantage of DCSs over PLC networks?

What is an advantage of DCSs over PLC networks?

What is a characteristic of DCSs that contributes to their reliability?

What is a characteristic of DCSs that contributes to their reliability?

What is a disadvantage of DCSs?

What is a disadvantage of DCSs?

What is a security concern for DCSs?

What is a security concern for DCSs?

What does SCADA stand for?

What does SCADA stand for?

What is the main purpose of a SCADA system?

What is the main purpose of a SCADA system?

What is a benefit of using a SCADA system?

What is a benefit of using a SCADA system?

What is the primary function of SCADA in a system?

What is the primary function of SCADA in a system?

What is the main difference between SCADA and DCS?

What is the main difference between SCADA and DCS?

What is the purpose of the data communication step in SCADA construction?

What is the purpose of the data communication step in SCADA construction?

What is the role of the control step in SCADA construction?

What is the role of the control step in SCADA construction?

What is the primary use of HMIs in a system?

What is the primary use of HMIs in a system?

Which system is best suited for connecting multiple factories located in different cities for real-time monitoring and control?

Which system is best suited for connecting multiple factories located in different cities for real-time monitoring and control?

What is the purpose of data presentation in SCADA construction?

What is the purpose of data presentation in SCADA construction?

What type of devices are used to collect data in the data acquisition step of SCADA construction?

What type of devices are used to collect data in the data acquisition step of SCADA construction?

Which system would you use to visualize the performance of a machine in a factory and respond to any issues?

Which system would you use to visualize the performance of a machine in a factory and respond to any issues?

What is the best system for running a steel plant with various processes like furnaces and rolling mills?

What is the best system for running a steel plant with various processes like furnaces and rolling mills?

Which system is ideal for monitoring and controlling the whole operation of a steel plant with various processes, each equipped with its own controller?

Which system is ideal for monitoring and controlling the whole operation of a steel plant with various processes, each equipped with its own controller?

What is the main difference between a DCS and a SCADA system?

What is the main difference between a DCS and a SCADA system?

Which system would you use to monitor and control individual processes in a factory?

Which system would you use to monitor and control individual processes in a factory?

What is the main advantage of using a DCS system in a factory?

What is the main advantage of using a DCS system in a factory?

Flashcards are hidden until you start studying

Study Notes

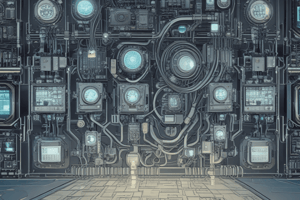

PLC Graphical Interface

- Efficient communication between humans and machines is essential in automation systems.

- Human-Machine Interface (HMI) serves as the vital link between humans and machines.

- HMI provides graphical interfaces to monitor and control industrial processes or equipment.

- HMI presents real-time data and system controls on a single screen.

HMI Definition and Function

- HMI stands for Human-Machine Interface.

- HMI enables operators to monitor and control industrial processes or equipment.

- HMI provides access to process data and allows operators to input commands executed by PLCs.

HMI Connection and Programming

- Inputs and outputs are connected to the PLC, and then the HMI is linked to the PLC to carry out tasks.

- PLCs are programmed to manage input/output signals and control logic.

- HMIs are programmed to create graphical interfaces to monitor and control processes.

DCS (Distributed Control System)

- DCS is used for large-scale and efficient control of complex processes in modern industries.

- DCS consists of multiple controllers distributed throughout a factory to control different interrelated processes.

- All controllers are interconnected with other devices, forming a network to control and monitor the whole factory.

DCS Construction

- In a factory environment, a DCS supervises several areas, each with its own set of inputs and outputs.

- DCS enables centralized control and monitoring of different areas across the factory.

- A DCS controller is responsible for executing control algorithms, managing input and output signals, and communicating with other devices within the network.

- A DCS control room includes components for monitoring and controlling industrial processes, such as engineering workstations, operator screens, and other devices.

DCS Advantages and Disadvantages

- Advantages:

- Centralized control and monitoring

- Scalability

- Redundancy

- Integration

- Real-time monitoring

- Disadvantages:

- Cost

- Complexity

- Maintenance

- Cybersecurity threats

SCADA (Supervisory Control And Data Acquisition) System

- SCADA is a system architecture that uses controllers, computers, communications, and graphical user interfaces to monitor and control different processes.

- SCADA is used to supervise non-DCS systems within a factory or remotely across different locations.

- SCADA construction involves:

- Data acquisition from various sensors and devices

- Data communication through wired or wireless methods

- Data presentation to operators

- Control of the system by operators

Scenario Answers

- Scenario (1): c. SCADA

- Scenario (2): a. HMI

- Scenario (3): d. DCS

- Scenario (4): c. SCADA

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.