Podcast

Questions and Answers

What type of ignition systems are used in turbine engines?

What type of ignition systems are used in turbine engines?

- Capacitor type ignition systems (correct)

- High-energy ignition units

- Continuous combustion systems

- Magneto systems

Turbine engines require continuous high-voltage sparks during operation.

Turbine engines require continuous high-voltage sparks during operation.

False (B)

What is the primary function of a turbine engine ignition system?

What is the primary function of a turbine engine ignition system?

to ignite the fuel in the combustion chamber during an engine start

Turbine engine ignition systems are rated in _____, or watt-seconds.

Turbine engine ignition systems are rated in _____, or watt-seconds.

What is the purpose of the igniter plugs in a turbine engine ignition system?

What is the purpose of the igniter plugs in a turbine engine ignition system?

What are the two basic types of igniters commonly used in turbine engines?

What are the two basic types of igniters commonly used in turbine engines?

Match the following components with their descriptions:

Match the following components with their descriptions:

What is the purpose of manually changing the ignition selection on successive engine starts?

What is the purpose of manually changing the ignition selection on successive engine starts?

The ignition exciters transform, rectify, and store energy in a capacitor.

The ignition exciters transform, rectify, and store energy in a capacitor.

What precautions should be taken before handling an opened or damaged igniter unit?

What precautions should be taken before handling an opened or damaged igniter unit?

High-energy ignition unit is potentially lethal due to the energy stored in a __________.

High-energy ignition unit is potentially lethal due to the energy stored in a __________.

What is the purpose of a continuous-duty ignition system in some engines?

What is the purpose of a continuous-duty ignition system in some engines?

How is the cooling of gas turbine engines ensured when continuous ignition is used for an extended period of time?

How is the cooling of gas turbine engines ensured when continuous ignition is used for an extended period of time?

In a capacitor-type ignition system, the generator producing power is turned directly by the engine.

In a capacitor-type ignition system, the generator producing power is turned directly by the engine.

The storage capacitor in a capacitor-type ignition system can accumulate a charge of up to approximately ____ joules.

The storage capacitor in a capacitor-type ignition system can accumulate a charge of up to approximately ____ joules.

What is a good procedure to perform before disconnecting the ignition lead?

What is a good procedure to perform before disconnecting the ignition lead?

Broken wires can be repaired by means of crimped splices, by using terminal lugs from which the tongue has been cut off, or by __________ broken strands.

Broken wires can be repaired by means of crimped splices, by using terminal lugs from which the tongue has been cut off, or by __________ broken strands.

The starter is an electromechanical mechanism capable of developing large amounts of mechanical energy.

The starter is an electromechanical mechanism capable of developing large amounts of mechanical energy.

What is the purpose of the engine starting system?

What is the purpose of the engine starting system?

What are the two subassemblies of the pressure-regulating and shutoff valve?

What are the two subassemblies of the pressure-regulating and shutoff valve?

A solenoid is used to stop the action of the control crank in the off position.

A solenoid is used to stop the action of the control crank in the off position.

What happens when the start valve is closed?

What happens when the start valve is closed?

Air at a pressure of approximately 35 to 40 psi enters the starter housing at its aft end and flows through the turbine nozzle where its direction is altered so that it enters the blades of the axial turbine at the proper angle. Air flowing through the turbine spins it at a speed of around __ RPM.

Air at a pressure of approximately 35 to 40 psi enters the starter housing at its aft end and flows through the turbine nozzle where its direction is altered so that it enters the blades of the axial turbine at the proper angle. Air flowing through the turbine spins it at a speed of around __ RPM.

What are the two principal disadvantages of cartridge/pneumatic turbine engine starters?

What are the two principal disadvantages of cartridge/pneumatic turbine engine starters?

How is a cartridge start initiated in the cartridge/pneumatic turbine engine starter?

How is a cartridge start initiated in the cartridge/pneumatic turbine engine starter?

The air impingement starter is a type of turbine engine starter that uses compressed air directed onto the turbine blades.

The air impingement starter is a type of turbine engine starter that uses compressed air directed onto the turbine blades.

The ________ starter was used to start gas turbine engines using the combustion energy of jet A fuel.

The ________ starter was used to start gas turbine engines using the combustion energy of jet A fuel.

Match the following components to their function in an electrical starter system:

Match the following components to their function in an electrical starter system:

What caution is mentioned when manually operating the start valve with the T-handle?

What caution is mentioned when manually operating the start valve with the T-handle?

What is the three-step procedure for using the T-handle on the start valve?

What is the three-step procedure for using the T-handle on the start valve?

What are the three general types of mechanical engine control systems mentioned?

What are the three general types of mechanical engine control systems mentioned?

What is the purpose of the ignition exciter in the starting system?

What is the purpose of the ignition exciter in the starting system?

How is the generator output current connected to the bus?

How is the generator output current connected to the bus?

The lubricant used in the starter-generator is of low-temperature type.

The lubricant used in the starter-generator is of low-temperature type.

The typical air turbine starter is designed to provide high starting torque from a small, lightweight source and weighs approximately ______ as much as an electric starter capable of starting the same engine.

The typical air turbine starter is designed to provide high starting torque from a small, lightweight source and weighs approximately ______ as much as an electric starter capable of starting the same engine.

Match the pneumatic sources with their description:

Match the pneumatic sources with their description:

Flashcards are hidden until you start studying

Study Notes

Turbine Engine Ignition Systems

- Turbine engine fuel requires a much hotter spark for ignition than aviation gasoline.

- Ignition systems are different from reciprocating engines, using continuous combustion and requiring electrical sparks only during start-up.

- Most turbine engine ignition systems have continuous or automatic relight settings that can be selected in flight.

High Energy Ignition Units (HEIU)

- Turbine engine ignition systems are rated in joules, with 4-joule systems used on smaller engines and 20-joule systems on larger engines.

- A high rate of current is needed to produce a spark intense enough to vaporize and ignite the fuel.

- Ignition systems can furnish this intense current without being excessively large or heavy.

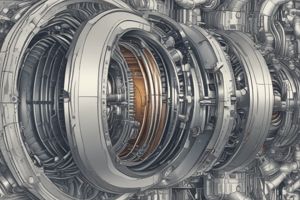

Capacitor Type Ignition System

- Most modern ignition systems produce high-energy sparks by storing high-voltage electrical energy in a capacitor and discharging it across the electrodes in the igniters.

- There are two types of high-energy, or capacitor-discharge, ignition systems: low-voltage systems with about 1,000 volts at the igniters, and high-voltage systems with an output of more than 5,000 volts.

Typical Turbine Engine Ignition System

- A typical turbine engine ignition system consists of two ignition exciters, two high-tension leads, and two igniters.

- The exciters, which convert the 28-volt DC or 115-volt AC into high voltage, are normally sealed units and cannot be serviced in the field.

Operation and Maintenance

- The ignition system is normally turned on for takeoff, landing, or flight into turbulent conditions, and when the engine anti-ice system is actuated.

- The tremendous amount of energy released by these ignition systems limits the length of time they can be used without a cooling-down period.

- The specific duty cycle for each system is found in the operator’s manual for the engine, and it must be carefully observed.### Turbine Engine Ignition System

- The gas in the discharge tube becomes conductive at a certain voltage, allowing the storage capacitor to discharge through it.

- The discharge current flows through the primary winding of the trigger transformer, inducing a high voltage into the secondary winding.

- The high voltage is connected to the igniter, causing the air in the gap to ionize and become conductive, producing a spark.

- The safety resistor bleeds off any stored energy in the trigger capacitor when the ignition system is shut down, preventing voltage buildup.

- The bleeder resistor bleeds off energy in the storage capacitor when the system is not operating.

AC Input Turbine Engine Ignition Exciter

- The system uses a voltage doubler circuit to increase the voltage from the aircraft electrical system.

- The voltage doubler circuit consists of a capacitor, resistor, diode, and storage capacitor.

- The charge on the storage capacitor increases with each cycle of the AC until it reaches the ionization voltage of the gas in the discharge tube.

Ignition Exciter Unit

- The ignition exciter unit is a small box mounted on the engine, containing electronic components encased in epoxy resin.

- It transforms the input voltage to a pulsed high-voltage output through solid-state circuitry, transformers, and diodes.

Igniter Plugs

- Turbine-engine igniters serve the same purpose as spark plugs in a reciprocating engine, but with higher energy requirements.

- Igniters are not prone to carbon fouling and are tailored to the specific engine.

- There are two basic types of igniters: spark igniters and glow plug igniters.

Ignition Leads

- Each ignition exciter unit is connected to its related igniter plug by a separate ignition cable.

- The cable assembly consists of a thick gauge nickel-plated copper stranded conductor lead covered in silicone rubber insulation, screened by encasing it in earthed nickel-plated copper braiding.

Ignition Control Circuits

- The ignition control circuit is used to energize the ignition system for starting and relighting the engine.

- The circuit includes an auto-ignition system, which serves as a backup for takeoff and landing, and for flight conditions in which the engine could flame out.

Typical Turbine Engine Ignition System

- The complete engine ignition system consists of two independent high-tension circuits, including two ignition exciters, two ignition lead assemblies, and two igniter plugs.

- The ignition system receives its electrical power from the aircraft AC bus through the electronic engine control (EEC).

- The EEC selects the left, right, or both igniter plugs based on the position of the flight compartment ignition selector switch.

System Operation

- The ignition exciters use 115 VAC to produce a 14,000 to 18,000 volt DC output at a rate of approximately one pulse per second to the igniter plugs.

- The exciters transform, rectify, and store energy in a capacitor at an energy level of 14.5 to 16 joules.

- The ignition leads carry the electrical energy to the igniter plugs, which are cooled by fan discharge air.### Ignition System

• Igniter plugs utilize a recessed surface gap and are insulated from the outer shell by aluminum oxide. • They thread into an igniter bushing, which threads into the combustion case. • The ignition lead and igniter plug arrangement is crucial for the ignition system.

Safety Precautions

• The energy stored in a high-energy ignition unit is potentially lethal. • Before touching any components, the ignition circuit breaker should be tripped, or the fuse removed. • The LT input to the unit should be removed, and at least one minute or the specified time should be allowed to elapse before touching the HT lead or the igniter plug. • Testing should never be done when fueling the aircraft or when personnel are in the jet efflux area of the engine.

Maintenance Practices

• The ignition system should be checked for security of component mounting, shorts, or high-voltage arcing, and loose connections. • The igniter can be checked by listening for a snapping noise as the engine begins to turn, driven by the starter. • The igniter can also be checked by removing it and activating the start cycle, noting the spark across the igniter.

Troubleshooting

• Apply logical troubleshooting procedures when investigating an ignition system problem. • Manufacturers provide troubleshooting charts to aid in diagnosing and repairing commonly encountered problems.

Removal and Installation

• Turbine engine ignition systems must be handled with extreme care because the high voltage can be lethal. • Before disconnecting the lead from an exciter or igniter, the ignition power circuit breaker should be pulled. • The power lead to the exciter should be disconnected, and the specified time should be allowed to elapse before removing the igniter lead. • The igniter lead should be removed from the engine, and the center conductor should be grounded to the engine to ensure the capacitors are completely discharged.

Emergency Splicing Repairs

• Broken wires can be repaired by means of crimped splices, by using terminal lugs, or by soldering together and potting broken strands. • These repairs are applicable to copper wire, but damaged aluminum wire must not be temporarily spliced.

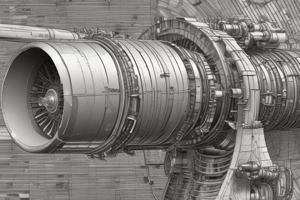

Gas Turbine Engine Starting System

• The starter is an electromechanical mechanism that develops large amounts of mechanical energy to turn the engine. • The starter must turn the engine up to a speed that provides enough airflow through the engine for fuel to be ignited. • Then, the starter must continue to help the engine accelerate to a self-sustaining speed.

Engine Starter Fundamentals

• Gas turbine engines are generally started by a starter connected to the main gearbox. • The starter rotates the compressor through the gearbox, providing sufficient air for combustion and aiding the engine in self-acceleration up to idle speed.

Types of Starters

• The basic types of starters that are in current use for gas turbine engines are direct current (DC) electric motor, starter/generators, and the air turbine type of starters. • The cartridge-type starter is an air-turbine starter operated by means of hot gases from a solid fuel cartridge instead of compressed air.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.