Podcast

Questions and Answers

What is the primary function of the compressor in a gas turbine engine?

What is the primary function of the compressor in a gas turbine engine?

- To increase air pressure and temperature (correct)

- To extract energy from hot gases

- To inject fuel into the combustion chamber

- To expel gases at high velocity

Which statement accurately describes the Brayton Cycle?

Which statement accurately describes the Brayton Cycle?

- It involves stages of compression, cooling, and expansion.

- It is a one-time cycle that does not repeat.

- It consists of continuous processes of compression, combustion, and expansion. (correct)

- It only encompasses the combustion stage of a gas turbine.

Which type of gas turbine engine is primarily used in helicopters?

Which type of gas turbine engine is primarily used in helicopters?

- Turbojet

- Turboshaft (correct)

- Turbofan

- Turboprop

What is a key advantage of gas turbine engines?

What is a key advantage of gas turbine engines?

What distinguishes a turbofan engine from a turbojet engine?

What distinguishes a turbofan engine from a turbojet engine?

What does a lower Specific Fuel Consumption (SFC) value indicate?

What does a lower Specific Fuel Consumption (SFC) value indicate?

Which of the following components is responsible for mixing fuel and air in a gas turbine engine?

Which of the following components is responsible for mixing fuel and air in a gas turbine engine?

What is a disadvantage associated with gas turbine engines?

What is a disadvantage associated with gas turbine engines?

Flashcards are hidden until you start studying

Study Notes

Overview

- A gas turbine engine, also known as a jet engine, converts fuel into mechanical energy through combustion.

- Commonly used in aviation, power generation, and industrial applications.

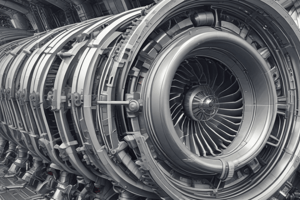

Components

-

Air Intake

- Draws in ambient air.

- Often equipped with a compressor.

-

Compressor

- Increases air pressure and temperature.

- Can be axial or centrifugal type.

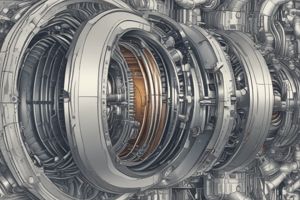

-

Combustion Chamber

- Fuel is injected and mixed with high-pressure air.

- Ignition occurs, resulting in high-temperature, high-pressure gas.

-

Turbine

- Extracts energy from hot gases.

- Drives the compressor and other accessories.

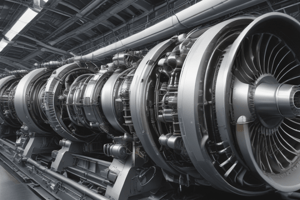

-

Exhaust

- Expels gases at high velocity to produce thrust or drive a generator.

Operating Principle

- Brayton Cycle: Continuous cycle involving compression, combustion, and expansion.

- Compression: Air is compressed to high pressure.

- Combustion: Fuel is burned with compressed air.

- Expansion: Gases expand through the turbine, producing work.

Types

-

Turbojet

- Simplest form; all air passes through the engine.

- High speed and efficiency at high altitudes.

-

Turbofan

- Features a large fan; provides additional thrust.

- More fuel-efficient and quieter than turbojets.

-

Turboprop

- Uses a propeller driven by a gas turbine.

- Suitable for lower speed and shorter distances.

-

Turboshaft

- Converts gas energy to shaft power.

- Primarily used in helicopters and industrial applications.

Performance Factors

- Thrust-to-Weight Ratio: Critical for aircraft performance.

- Specific Fuel Consumption (SFC): Efficiency metric; lower values are better.

- Operating Temperature: Higher temperatures improve efficiency but can affect material durability.

Advantages

- High power-to-weight ratio.

- Ability to operate on various fuels.

- Versatile applications across different sectors.

Disadvantages

- High initial cost and maintenance.

- Relies heavily on high-quality materials to withstand operating conditions.

- Environmental concerns related to emissions and noise.

Overview

- A gas turbine engine, or jet engine, transforms fuel into mechanical energy through combustion.

- Widely utilized in aviation, power generation, and various industrial settings.

Components

- Air Intake: Incorporates ambient air and is usually paired with a compressor to optimize intake efficiency.

- Compressor: Enhances air pressure and temperature; may be categorized as axial or centrifugal type depending on design.

- Combustion Chamber: Combines fuel with compressed air to ignite, creating high-temperature and high-pressure gases.

- Turbine: Harnesses energy from hot gases, which powers the compressor and other engine accessories.

- Exhaust: Discharges gases at high velocity, generating thrust in aircraft or driving generators in power applications.

Operating Principle

- Operates on the Brayton Cycle, which consists of continuous phases: compression, combustion, and expansion.

- Compression: Air is compressed, significantly raising its pressure.

- Combustion: Burning of fuel occurs with the already compressed air.

- Expansion: The produced gases expand and flow through the turbine, generating work.

Types

- Turbojet: The simplest form where all air passes through the engine, providing high speed and efficiency at altitude.

- Turbofan: Equipped with a large fan, adds thrust efficiency, resulting in quieter operation and improved fuel economy compared to turbojets.

- Turboprop: Incorporates a propeller powered by a gas turbine, best for lower speeds and shorter distances.

- Turboshaft: Converts gas energy to rotational power, mainly employed in helicopter systems and industrial machinery.

Performance Factors

- Thrust-to-Weight Ratio: A vital parameter for assessing aircraft performance and capability.

- Specific Fuel Consumption (SFC): A measure of efficiency, emphasizing that lower values denote better performance.

- Operating Temperature: Higher temperatures can enhance efficiency but may adversely affect material longevity and integrity.

Advantages

- Exhibits a high power-to-weight ratio, enhancing overall performance.

- Capable of utilizing various fuel types, adding operational versatility.

- Adaptable across a myriad of applications in diverse sectors.

Disadvantages

- Characterized by high initial costs and significant maintenance requirements.

- Depends on high-quality materials to endure challenging operational conditions.

- Associated environmental issues, particularly concerning emissions and noise pollution.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.