Podcast

Questions and Answers

What is the primary objective of an air intake in a gas turbine engine?

What is the primary objective of an air intake in a gas turbine engine?

- To minimize energy loss during air delivery to the engine (correct)

- To increase the engine's power output

- To cool the engine during operation

- To reduce the engine's noise levels

Why is it crucial to maintain the inlet duct in good condition?

Why is it crucial to maintain the inlet duct in good condition?

- To prevent corrosion and abrasion

- To improve the engine's fuel efficiency

- To minimize airflow turbulence and efficiency loss (correct)

- To reduce engine vibration

What is the purpose of an inlet cover?

What is the purpose of an inlet cover?

- To reduce the engine's thrust output

- To promote cleanliness and prevent corrosion and abrasion (correct)

- To increase the engine's operating temperature

- To improve airflow into the engine

Why are expertly installed flush patches necessary for inlet duct repairs?

Why are expertly installed flush patches necessary for inlet duct repairs?

What is the typical location of the air entrance or flight inlet duct?

What is the typical location of the air entrance or flight inlet duct?

What is the compressor inlet air requirement to operate satisfactorily?

What is the compressor inlet air requirement to operate satisfactorily?

What is the primary purpose of a movable wedge inlet?

What is the primary purpose of a movable wedge inlet?

What is a disadvantage of using bellmouth inlets?

What is a disadvantage of using bellmouth inlets?

What occurs at the inlet during transonic flight with the movable spike extended?

What occurs at the inlet during transonic flight with the movable spike extended?

Why are mesh screens used in bellmouth ducts?

Why are mesh screens used in bellmouth ducts?

What happens to the bow wave as airspeed increases to supersonic?

What happens to the bow wave as airspeed increases to supersonic?

What is a limitation of using inlet screens in aircraft?

What is a limitation of using inlet screens in aircraft?

What is a characteristic feature of bellmouth inlets?

What is a characteristic feature of bellmouth inlets?

Where can inlet screens be located?

Where can inlet screens be located?

Why are bellmouth inlets used on helicopters and engine test cells?

Why are bellmouth inlets used on helicopters and engine test cells?

What is the function of the 'mouse' in a movable spike inlet?

What is the function of the 'mouse' in a movable spike inlet?

What is a unique feature of a type of separator used on some turboprop aircraft?

What is a unique feature of a type of separator used on some turboprop aircraft?

What type of aircraft are bellmouth inlets often used on?

What type of aircraft are bellmouth inlets often used on?

When should the anti-icing heat be turned on?

When should the anti-icing heat be turned on?

What can happen if the anti-ice system is used to de-ice the inlet area after compressor stalls occur from ice formation?

What can happen if the anti-ice system is used to de-ice the inlet area after compressor stalls occur from ice formation?

What type of system is used in some smaller turboprop and turboshaft engines?

What type of system is used in some smaller turboprop and turboshaft engines?

Where are electric heat strips typically located in electro-thermal anti-icing systems?

Where are electric heat strips typically located in electro-thermal anti-icing systems?

Why should the electro-thermal anti-icing system not be operated without air passing over it?

Why should the electro-thermal anti-icing system not be operated without air passing over it?

What is used in some systems to anti-ice the engine and inlet?

What is used in some systems to anti-ice the engine and inlet?

What is the primary function of secondary air inlet doors in some aircraft?

What is the primary function of secondary air inlet doors in some aircraft?

What can occur if the aircraft or conditions exceed expected flight attitudes?

What can occur if the aircraft or conditions exceed expected flight attitudes?

Why is it important to face an aircraft into the wind before carrying out an engine ground run?

Why is it important to face an aircraft into the wind before carrying out an engine ground run?

What is a common cause of compressor stall during ground running?

What is a common cause of compressor stall during ground running?

How can the pressure required to open the secondary air inlet doors be altered?

How can the pressure required to open the secondary air inlet doors be altered?

Which aircraft are very susceptible to crosswind-induced compressor stall with power settings above idle?

Which aircraft are very susceptible to crosswind-induced compressor stall with power settings above idle?

Flashcards are hidden until you start studying

Study Notes

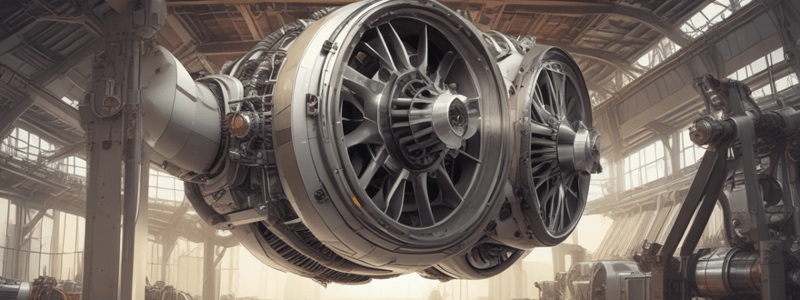

Compressor Inlet Ducts

- The air intake must provide air to the compressor with minimal loss of energy and uniform pressure distribution across the inlet area.

- The air entrance or flight inlet duct is considered part of the airframe, not the engine, but is identified as Engine Station 1.

- The inlet duct's function is crucial to engine performance, and even small discontinuities can cause significant efficiency loss and engine performance problems.

- The inlet duct must be maintained in close to new condition to prevent drag, and repairs should be done with expertly installed flush patches.

- The use of an inlet cover is recommended to promote cleanliness and prevent corrosion and abrasion.

Movable Inlet Ducts

- A movable spike or plug can be used to alter the shape of the inlet as aircraft speed changes, creating a movable C-D inlet.

- During transonic flight, the movable spike is extended to produce a normal shock wave, and as airspeed increases, the spike is repositioned to shift the C-D duct for an optimum inlet shape.

- At supersonic speeds, the bow wave changes to multiple oblique shock waves, and a normal shock wave develops at the lip of the inlet.

Bellmouth Inlets

- Bellmouth compressor inlets are convergent in shape and are commonly found on helicopters and engine test cells.

- They present a mouth wider in circumference than the engine compressor inlet, smoothly converging to funnel air down to the compressor inlet circumference.

- Bellmouth inlets eliminate the 'necking down' effect of an airstream passing through a plain orifice, allowing the engine to draw all the air it can use.

- They are often used during ground testing and calibration, fitted with mesh screens to protect technicians from ingestion hazards.

Inlet Screens

- The use of compressor inlet screens is usually limited to rotorcraft, turboprops, and ground turbine installations.

- Screens have been tried in high subsonic flight engines, but icing and screen fatigue failure caused maintenance problems.

- Screens may be located internally or externally at either the inlet duct or compressor inlet.

Secondary Air Inlet Doors

- Some aircraft use a system of doors that allow extra air into the inlet duct, reacting to excess negative pressure within the inlet.

- The suck-in doors are pushed open by high external air pressure, allowing extra airflow to the compressor.

- The pressure required to open the door can be altered by adjusting the tension of the door spring.

Inlet Duct Losses

- Inlet duct losses can occur if the aircraft or conditions exceed expected flight attitudes, such as high AOAs or sideslipping, disrupting the smooth inlet airflow into the inlet duct.

- This can lead to compressor stall, and some aircraft are more prone to this phenomenon than others.

- During ground running, crosswinds can disrupt the inlet airflow and increase the AOA of the air into the compressor, causing compressor stall.

Inlet Anti-ice

- Anti-icing systems are used to prevent ice formation on the inlet area, which can cause compressor stall or engine failure.

- During flight, the anti-icing system is turned on before entering the icing condition.

- Some smaller turboprop and turboshaft engines use electric heat strip systems, which are cycled on and off as required by ambient conditions.

- Other systems use hot engine or reduction gearbox oil to anti-ice the engine and inlet.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.