Podcast

Questions and Answers

EASY What is the first step to take before starting up a new boiler?

EASY What is the first step to take before starting up a new boiler?

- Check the altitude gauge on the boiler

- Open the isolation valve between the expansion tank and the heating system

- Make sure the boiler has a valid inspection certificate (correct)

- Review the manufacturer's recommendations for startup

What should you check on the boiler before startup?

What should you check on the boiler before startup?

- The altitude gauge (correct)

- The expansion tank level

- The fuel system

- The isolation valve

Why is it important to check the altitude gauge?

Why is it important to check the altitude gauge?

- To ensure the boiler is not over-pressurized

- To ensure the system is under minimum static pressure (correct)

- To ensure the boiler is not leaking

- To ensure the boiler is not under-pressurized

What should you do if the expansion tank level is high?

What should you do if the expansion tank level is high?

What should you refer to for site-specific procedures?

What should you refer to for site-specific procedures?

What is the purpose of reviewing the manufacturer's recommendations?

What is the purpose of reviewing the manufacturer's recommendations?

Why is it important to ensure the boiler has a valid inspection certificate?

Why is it important to ensure the boiler has a valid inspection certificate?

What should you do after draining the expansion tank?

What should you do after draining the expansion tank?

What should be done to the primary heating loop circulator pump?

What should be done to the primary heating loop circulator pump?

Why is it important to vent the air at high points in the system?

Why is it important to vent the air at high points in the system?

What is the purpose of checking the fuel and fresh air supplies?

What is the purpose of checking the fuel and fresh air supplies?

What should be done to the boiler control switch on the panel?

What should be done to the boiler control switch on the panel?

What should be done to the control switch on the panel for boilers with high-low firing rate control?

What should be done to the control switch on the panel for boilers with high-low firing rate control?

What should be done to the low water fuel cutoff or high limit control with mechanical reset devices?

What should be done to the low water fuel cutoff or high limit control with mechanical reset devices?

MEDIUM What is the primary reason for venting air at high points in the system?

MEDIUM What is the primary reason for venting air at high points in the system?

What is the purpose of checking the fuel and fresh air supplies?

What is the purpose of checking the fuel and fresh air supplies?

What should be done to the secondary circulator pumps?

What should be done to the secondary circulator pumps?

What is the purpose of setting the control switch to low on boilers with a high-low firing rate control?

What is the purpose of setting the control switch to low on boilers with a high-low firing rate control?

What should be done to the low water fuel cutoff or high limit control with mechanical reset devices?

What should be done to the low water fuel cutoff or high limit control with mechanical reset devices?

What is the final step before starting up a boiler?

What is the final step before starting up a boiler?

What should be checked before filling the boiler with water?

What should be checked before filling the boiler with water?

What is the purpose of verifying the minimum static pressure on the altitude gauge?

What is the purpose of verifying the minimum static pressure on the altitude gauge?

What should be done if the expansion tank level is in the upper part of the gauge?

What should be done if the expansion tank level is in the upper part of the gauge?

Why is it important to review the manufacturer's recommendations for startup?

Why is it important to review the manufacturer's recommendations for startup?

What should be referred to for site-specific procedures for multiple boilers sharing a common expansion tank?

What should be referred to for site-specific procedures for multiple boilers sharing a common expansion tank?

What is the primary purpose of checking the isolation valve between the expansion tank and the heating system?

What is the primary purpose of checking the isolation valve between the expansion tank and the heating system?

Why is it important to ensure the boiler has a valid inspection certificate?

Why is it important to ensure the boiler has a valid inspection certificate?

What should be done to the expansion tank after draining and venting?

What should be done to the expansion tank after draining and venting?

HARD What is the primary purpose of ensuring the boiler control switch on the panel is in the off position before startup?

HARD What is the primary purpose of ensuring the boiler control switch on the panel is in the off position before startup?

Why is it necessary to vent air at high points in the system?

Why is it necessary to vent air at high points in the system?

What is the purpose of checking the fuel and fresh air supplies before startup?

What is the purpose of checking the fuel and fresh air supplies before startup?

What is the correct procedure for boilers with a fully modulating firing rate control?

What is the correct procedure for boilers with a fully modulating firing rate control?

What is the purpose of pushing the reset buttons on the low water fuel cutoff or high limit control with mechanical reset devices?

What is the purpose of pushing the reset buttons on the low water fuel cutoff or high limit control with mechanical reset devices?

What is the final step before starting up a boiler, according to the provided procedure?

What is the final step before starting up a boiler, according to the provided procedure?

What is the primary purpose of reviewing the manufacturer's recommendations for startup?

What is the primary purpose of reviewing the manufacturer's recommendations for startup?

What is the significance of the altitude gauge on the boiler?

What is the significance of the altitude gauge on the boiler?

What is the consequence of not ensuring the boiler has a valid inspection certificate?

What is the consequence of not ensuring the boiler has a valid inspection certificate?

What should be done if the expansion tank level is high?

What should be done if the expansion tank level is high?

Why is it important to check the isolation valve between the expansion tank and the heating system?

Why is it important to check the isolation valve between the expansion tank and the heating system?

What should be referred to for site-specific procedures for multiple boilers sharing a common expansion tank?

What should be referred to for site-specific procedures for multiple boilers sharing a common expansion tank?

What is the primary purpose of ensuring the boiler has a valid inspection certificate?

What is the primary purpose of ensuring the boiler has a valid inspection certificate?

What should be done after venting and draining the expansion tank?

What should be done after venting and draining the expansion tank?

Match the following steps with their corresponding actions:

Match the following steps with their corresponding actions:

Match the following situations with their corresponding actions:

Match the following situations with their corresponding actions:

Match the following gauges with their corresponding functions:

Match the following gauges with their corresponding functions:

Match the following steps with their corresponding purposes:

Match the following steps with their corresponding purposes:

Match the following situations with their corresponding consequences:

Match the following situations with their corresponding consequences:

Match the following actions with their corresponding purposes:

Match the following actions with their corresponding purposes:

Match the following steps with their corresponding sequences:

Match the following steps with their corresponding sequences:

Match the following components with their corresponding functions:

Match the following components with their corresponding functions:

Match the following boiler startup procedures with their corresponding actions:

Match the following boiler startup procedures with their corresponding actions:

Match the following boiler components with their corresponding purposes:

Match the following boiler components with their corresponding purposes:

Match the following boiler startup procedures with their corresponding purposes:

Match the following boiler startup procedures with their corresponding purposes:

Match the following boiler components with their corresponding settings:

Match the following boiler components with their corresponding settings:

Match the following boiler startup procedures with their corresponding consequences:

Match the following boiler startup procedures with their corresponding consequences:

Match the following boiler components with their corresponding actions:

Match the following boiler components with their corresponding actions:

Flashcards are hidden until you start studying

Study Notes

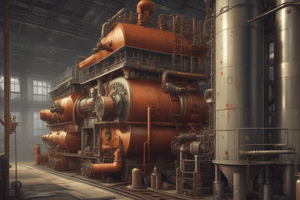

Preparation for Startup

- Ensure the boiler has a valid inspection certificate before startup or after a prolonged shutdown.

- Review the manufacturer's recommendations for startup and operation.

Pre-Startup Checks

- Verify the boiler's altitude gauge indicates a minimum static pressure to maintain positive pressure at the highest point in the system.

- Ensure the isolation valve between the expansion tank and the heating system is open.

- Check the expansion tank level, and if high, drain and vent the tank to the correct level.

Expansion Tank Preparation

- If multiple boilers share a common expansion tank, follow site-specific procedures to ensure all on-line boilers are serviced.

- Ensure the expansion tank isolation valve is open.

Heating System Preparation

- Start the primary heating loop circulator pump and vent air at high points in the system until a solid stream of water flows.

- If the system has secondary heating loops, start the secondary circulator pumps following site-specific procedures.

Fuel and Air Supply Checks

- Check the fuel and fresh air supplies before startup.

- Verify the temperature setting of the high limit control.

Boiler Controls

- Ensure the boiler control switch on the panel is in the off position before startup.

- Set the control switch to low on boilers with a high-low firing rate control.

- For boilers with a fully modulating firing rate control, set the manual-automatic switch to manual and the flame control switch to low-fire.

Final Checks

- Push the reset buttons on the low water fuel cutoff and high limit control if equipped with mechanical reset devices.

- Ensure all checks are complete before starting the boiler.

Preparation for Startup

- Ensure the boiler has a valid inspection certificate before startup or after a prolonged shutdown.

- Review the manufacturer's recommendations for startup and operation.

Pre-Startup Checks

- Verify the boiler's altitude gauge indicates a minimum static pressure to maintain positive pressure at the highest point in the system.

- Ensure the isolation valve between the expansion tank and the heating system is open.

- Check the expansion tank level, and if high, drain and vent the tank to the correct level.

Expansion Tank Preparation

- If multiple boilers share a common expansion tank, follow site-specific procedures to ensure all on-line boilers are serviced.

- Ensure the expansion tank isolation valve is open.

Heating System Preparation

- Start the primary heating loop circulator pump and vent air at high points in the system until a solid stream of water flows.

- If the system has secondary heating loops, start the secondary circulator pumps following site-specific procedures.

Fuel and Air Supply Checks

- Check the fuel and fresh air supplies before startup.

- Verify the temperature setting of the high limit control.

Boiler Controls

- Ensure the boiler control switch on the panel is in the off position before startup.

- Set the control switch to low on boilers with a high-low firing rate control.

- For boilers with a fully modulating firing rate control, set the manual-automatic switch to manual and the flame control switch to low-fire.

Final Checks

- Push the reset buttons on the low water fuel cutoff and high limit control if equipped with mechanical reset devices.

- Ensure all checks are complete before starting the boiler.

Preparation for Startup

- Ensure the boiler has a valid inspection certificate before startup or after a prolonged shutdown.

- Review the manufacturer's recommendations for startup and operation.

Pre-Startup Checks

- Verify the boiler's altitude gauge indicates a minimum static pressure to maintain positive pressure at the highest point in the system.

- Ensure the isolation valve between the expansion tank and the heating system is open.

- Check the expansion tank level, and if high, drain and vent the tank to the correct level.

Expansion Tank Preparation

- If multiple boilers share a common expansion tank, follow site-specific procedures to ensure all on-line boilers are serviced.

- Ensure the expansion tank isolation valve is open.

Heating System Preparation

- Start the primary heating loop circulator pump and vent air at high points in the system until a solid stream of water flows.

- If the system has secondary heating loops, start the secondary circulator pumps following site-specific procedures.

Fuel and Air Supply Checks

- Check the fuel and fresh air supplies before startup.

- Verify the temperature setting of the high limit control.

Boiler Controls

- Ensure the boiler control switch on the panel is in the off position before startup.

- Set the control switch to low on boilers with a high-low firing rate control.

- For boilers with a fully modulating firing rate control, set the manual-automatic switch to manual and the flame control switch to low-fire.

Final Checks

- Push the reset buttons on the low water fuel cutoff and high limit control if equipped with mechanical reset devices.

- Ensure all checks are complete before starting the boiler.

Preparation for Startup

- Ensure the boiler has a valid inspection certificate before startup or after a prolonged shutdown.

- Review the manufacturer's recommendations for startup and operation.

Pre-Startup Checks

- Verify the boiler's altitude gauge indicates a minimum static pressure to maintain positive pressure at the highest point in the system.

- Ensure the isolation valve between the expansion tank and the heating system is open.

- Check the expansion tank level, and if high, drain and vent the tank to the correct level.

Expansion Tank Preparation

- If multiple boilers share a common expansion tank, follow site-specific procedures to ensure all on-line boilers are serviced.

- Ensure the expansion tank isolation valve is open.

Heating System Preparation

- Start the primary heating loop circulator pump and vent air at high points in the system until a solid stream of water flows.

- If the system has secondary heating loops, start the secondary circulator pumps following site-specific procedures.

Fuel and Air Supply Checks

- Check the fuel and fresh air supplies before startup.

- Verify the temperature setting of the high limit control.

Boiler Controls

- Ensure the boiler control switch on the panel is in the off position before startup.

- Set the control switch to low on boilers with a high-low firing rate control.

- For boilers with a fully modulating firing rate control, set the manual-automatic switch to manual and the flame control switch to low-fire.

Final Checks

- Push the reset buttons on the low water fuel cutoff and high limit control if equipped with mechanical reset devices.

- Ensure all checks are complete before starting the boiler.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.