Podcast

Questions and Answers

EASY What should be done if the burner continues to smoke?

EASY What should be done if the burner continues to smoke?

- Adjust the air-fuel ratio (correct)

- Call the local jurisdiction

- Check for condensation

- Turn off the boiler

Why do colder boilers experience condensation?

Why do colder boilers experience condensation?

- When the water vapour in the flue gases contacts the cold heating surfaces (correct)

- Because of thermal shock

- Due to uneven expansion

- Because of scale buildup

What happens when a cold boiler is first started?

What happens when a cold boiler is first started?

- The boiler starts heating up rapidly

- The boiler starts leaking

- Flue gas condensation takes place (correct)

- The boiler starts producing steam

What is the effect of high firing rates on boilers?

What is the effect of high firing rates on boilers?

What is uneven expansion?

What is uneven expansion?

What is the effect of scale buildup on the furnace and firetubes?

What is the effect of scale buildup on the furnace and firetubes?

What is thermal shock?

What is thermal shock?

What is the effect of rapid temperature changes on boilers?

What is the effect of rapid temperature changes on boilers?

Why is it important to avoid rapid heating of cold boilers?

Why is it important to avoid rapid heating of cold boilers?

What can cause a rapid drop in temperature in boilers?

What can cause a rapid drop in temperature in boilers?

What should an operator do if abnormal conditions occur during the light-off or warm-up period of a boiler?

What should an operator do if abnormal conditions occur during the light-off or warm-up period of a boiler?

Why may slight smoking occur during the warm-up period of a cold oil-fired boiler?

Why may slight smoking occur during the warm-up period of a cold oil-fired boiler?

What should be done if slight smoking persists after the boiler is warmed up?

What should be done if slight smoking persists after the boiler is warmed up?

What is the purpose of paying attention to boiler warm-up rates?

What is the purpose of paying attention to boiler warm-up rates?

What should be done before restarting a boiler after an abnormal condition has been identified and corrected?

What should be done before restarting a boiler after an abnormal condition has been identified and corrected?

Which of the following conditions is not typically encountered during the warm-up period of a boiler?

Which of the following conditions is not typically encountered during the warm-up period of a boiler?

What should be done to ensure that combustion is entirely complete during the warm-up period of a cold oil-fired boiler?

What should be done to ensure that combustion is entirely complete during the warm-up period of a cold oil-fired boiler?

What is the primary reason for paying attention to boiler warm-up rates?

What is the primary reason for paying attention to boiler warm-up rates?

What can be a source of cold water that can cause thermal shock to a steam heating boiler?

What can be a source of cold water that can cause thermal shock to a steam heating boiler?

What is the purpose of warming up a boiler slowly?

What is the purpose of warming up a boiler slowly?

What factors affect the rate at which a boiler can be brought up to its normal operating temperature and pressure?

What factors affect the rate at which a boiler can be brought up to its normal operating temperature and pressure?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What should be checked during the boiler warm-up process?

What should be checked during the boiler warm-up process?

Why should the firing rate be kept on manual low-fire control during the boiler warm-up process?

Why should the firing rate be kept on manual low-fire control during the boiler warm-up process?

What should be done to the boiler water level control system after the boiler is started?

What should be done to the boiler water level control system after the boiler is started?

Why should the boiler be continually monitored during the warm-up process?

Why should the boiler be continually monitored during the warm-up process?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What should be verified after the boiler warm-up process is complete?

What should be verified after the boiler warm-up process is complete?

medium What happens to the combustion process in a cold oil-fired boiler when it is first started?

medium What happens to the combustion process in a cold oil-fired boiler when it is first started?

What is a normal condition encountered during the warm-up period of a boiler?

What is a normal condition encountered during the warm-up period of a boiler?

Why is it important to pay attention to boiler warm-up rates?

Why is it important to pay attention to boiler warm-up rates?

What should be done if an abnormal condition occurs during the light-off or warm-up period of a boiler?

What should be done if an abnormal condition occurs during the light-off or warm-up period of a boiler?

What should be checked before restarting a boiler after an abnormal condition has been identified and corrected?

What should be checked before restarting a boiler after an abnormal condition has been identified and corrected?

What is a common condition that may disappear after the boiler is hot?

What is a common condition that may disappear after the boiler is hot?

What should be done if an atomizing air or steam pressure is incorrect?

What should be done if an atomizing air or steam pressure is incorrect?

What is recommended by the ASME VI Recommended Rules for the Care and Operation of Heating Boilers in case of abnormal conditions?

What is recommended by the ASME VI Recommended Rules for the Care and Operation of Heating Boilers in case of abnormal conditions?

What is the primary cause of condensation in boilers?

What is the primary cause of condensation in boilers?

Why is it important to know the damage caused by cold start conditions?

Why is it important to know the damage caused by cold start conditions?

What is the effect of scale buildup on the furnace and firetubes?

What is the effect of scale buildup on the furnace and firetubes?

What occurs when metal is subjected to a sudden change in temperature?

What occurs when metal is subjected to a sudden change in temperature?

Why is it important to avoid rapid heating of cold boilers?

Why is it important to avoid rapid heating of cold boilers?

What is the effect of high firing rates on firetube boilers?

What is the effect of high firing rates on firetube boilers?

Why is it essential to ensure combustion is entirely complete during the warm-up period?

Why is it essential to ensure combustion is entirely complete during the warm-up period?

What is the recommended approach to starting up a cold boiler?

What is the recommended approach to starting up a cold boiler?

What is the typical consequence of uneven expansion in firetube boilers?

What is the typical consequence of uneven expansion in firetube boilers?

Why is it important to monitor the boiler during the warm-up process?

Why is it important to monitor the boiler during the warm-up process?

What is a common source of cold water that can cause thermal shock to a steam heating boiler?

What is a common source of cold water that can cause thermal shock to a steam heating boiler?

What is the primary reason for warming up a boiler slowly?

What is the primary reason for warming up a boiler slowly?

What factors affect the rate at which a boiler can be brought up to its normal operating temperature and pressure?

What factors affect the rate at which a boiler can be brought up to its normal operating temperature and pressure?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What should be checked during the boiler warm-up process?

What should be checked during the boiler warm-up process?

Why should the firing rate be kept on manual low-fire control during the boiler warm-up process?

Why should the firing rate be kept on manual low-fire control during the boiler warm-up process?

What should be done to the boiler water level control system after the boiler is started?

What should be done to the boiler water level control system after the boiler is started?

Why should the boiler be continually monitored during the warm-up process?

Why should the boiler be continually monitored during the warm-up process?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What should be verified after the boiler warm-up process is complete?

What should be verified after the boiler warm-up process is complete?

HARD What is the primary reason for paying attention to boiler warm-up rates as prescribed by boiler manufacturers?

HARD What is the primary reason for paying attention to boiler warm-up rates as prescribed by boiler manufacturers?

What should an operator do if an abnormal condition occurs during the light-off or warm-up period of a boiler?

What should an operator do if an abnormal condition occurs during the light-off or warm-up period of a boiler?

What is a common condition that may disappear after the boiler is hot during the warm-up period?

What is a common condition that may disappear after the boiler is hot during the warm-up period?

What is the recommended approach to starting up a cold boiler?

What is the recommended approach to starting up a cold boiler?

What is the primary cause of condensation in boilers during the warm-up period?

What is the primary cause of condensation in boilers during the warm-up period?

What should be checked before restarting a boiler after an abnormal condition has been identified and corrected?

What should be checked before restarting a boiler after an abnormal condition has been identified and corrected?

What is the primary purpose of warming up a boiler slowly?

What is the primary purpose of warming up a boiler slowly?

What is the effect of rapid temperature changes on boilers?

What is the effect of rapid temperature changes on boilers?

What is the purpose of ensuring that combustion is entirely complete during the warm-up period of a cold oil-fired boiler?

What is the purpose of ensuring that combustion is entirely complete during the warm-up period of a cold oil-fired boiler?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What is the recommended rate of temperature increase for larger boilers to prevent thermal shock?

What should be checked during the boiler warm-up process?

What should be checked during the boiler warm-up process?

What is the primary reason for paying attention to boiler warm-up rates?

What is the primary reason for paying attention to boiler warm-up rates?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What should be done when the boiler pressure approaches its normal pressure or temperature set point?

What is the effect of rapid temperature changes on boilers?

What is the effect of rapid temperature changes on boilers?

What should be done before restarting a boiler after an abnormal condition has been identified and corrected?

What should be done before restarting a boiler after an abnormal condition has been identified and corrected?

What is the primary cause of condensation in boilers?

What is the primary cause of condensation in boilers?

What should be done to prevent thermal shock in steam heating boilers?

What should be done to prevent thermal shock in steam heating boilers?

What is the typical consequence of uneven expansion in firetube boilers?

What is the typical consequence of uneven expansion in firetube boilers?

What is the primary reason for the formation of tiny cracks in the metal of a boiler?

What is the primary reason for the formation of tiny cracks in the metal of a boiler?

What is the consequence of rapid heating of a cold boiler?

What is the consequence of rapid heating of a cold boiler?

What is the effect of scale buildup on the furnace and firetubes?

What is the effect of scale buildup on the furnace and firetubes?

What is the primary reason for avoiding rapid heating of cold boilers?

What is the primary reason for avoiding rapid heating of cold boilers?

What is the consequence of uneven expansion in firetube boilers?

What is the consequence of uneven expansion in firetube boilers?

What is the purpose of adjusting the air-fuel ratio in a boiler?

What is the purpose of adjusting the air-fuel ratio in a boiler?

What is the primary cause of condensation in boilers?

What is the primary cause of condensation in boilers?

What is the effect of high firing rates on firetube boilers?

What is the effect of high firing rates on firetube boilers?

What is the recommended approach to starting up a cold boiler?

What is the recommended approach to starting up a cold boiler?

What is the consequence of sudden changes in temperature in boilers?

What is the consequence of sudden changes in temperature in boilers?

Match the following conditions encountered during the warm-up period of a boiler with their corresponding description:

Match the following conditions encountered during the warm-up period of a boiler with their corresponding description:

Match the following consequences of boiler operation with their corresponding reasons:

Match the following consequences of boiler operation with their corresponding reasons:

Match the following actions with their corresponding situations:

Match the following actions with their corresponding situations:

Match the following guidelines with their corresponding sources:

Match the following guidelines with their corresponding sources:

Match the following terms with their corresponding definitions:

Match the following terms with their corresponding definitions:

Match the following scenarios with their corresponding consequences:

Match the following scenarios with their corresponding consequences:

Match the following actions with their corresponding goals:

Match the following actions with their corresponding goals:

Match the following conditions with their corresponding effects on boilers:

Match the following conditions with their corresponding effects on boilers:

Match the following boiler components with their potential problems during startup:

Match the following boiler components with their potential problems during startup:

Match the following precautions with their purpose during boiler startup:

Match the following precautions with their purpose during boiler startup:

Match the following boiler conditions with their potential consequences:

Match the following boiler conditions with their potential consequences:

Match the following boiler startup procedures with their purposes:

Match the following boiler startup procedures with their purposes:

Match the following boiler components with their potential effects on combustion:

Match the following boiler components with their potential effects on combustion:

Match the following boiler startup conditions with their potential causes:

Match the following boiler startup conditions with their potential causes:

Match the following boiler components with their normal operating conditions:

Match the following boiler components with their normal operating conditions:

Match the following boiler startup procedures with their recommended rates:

Match the following boiler startup procedures with their recommended rates:

Match the following boiler components with their potential effects on boiler performance:

Match the following boiler components with their potential effects on boiler performance:

Match the following boiler startup conditions with their recommended actions:

Match the following boiler startup conditions with their recommended actions:

Match the following boiler components with their characteristics:

Match the following boiler components with their characteristics:

Match the following boiler conditions with their consequences:

Match the following boiler conditions with their consequences:

Match the following boiler components with their effects:

Match the following boiler components with their effects:

Match the following boiler conditions with their causes:

Match the following boiler conditions with their causes:

Match the following boiler operations with their effects:

Match the following boiler operations with their effects:

Match the following boiler components with their characteristics:

Match the following boiler components with their characteristics:

Match the following boiler conditions with their consequences:

Match the following boiler conditions with their consequences:

Match the following boiler operations with their effects:

Match the following boiler operations with their effects:

Match the following boiler components with their characteristics:

Match the following boiler components with their characteristics:

Match the following boiler conditions with their causes:

Match the following boiler conditions with their causes:

Flashcards are hidden until you start studying

Study Notes

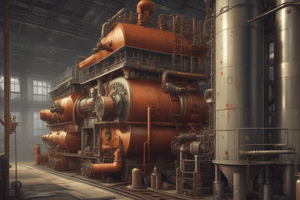

Boiler Startup and Warm-Up

- Operators must be aware of the effects of rapid heating on boiler metal and the importance of proper warm-up rates to prevent leaks, premature boiler failure, and ensure safety.

Abnormal Conditions During Startup

- Abnormal conditions may occur during light-off or warm-up period, requiring immediate shutdown and correction of the problem before restarting the boiler.

Normal Cold Start Conditions

- Slight smoking may occur during startup due to incomplete combustion, but should disappear after the boiler is hot.

- Condensation may occur in cold boilers, especially firetube boilers, causing water to run out of the reversing chamber doors, but will stop when the boiler is hot.

Harmful Cold Start Conditions

- Rapid heating can cause thermal shock, uneven expansion, and refractory damage, leading to leakage, premature boiler failure, and costly repairs.

- High firing rates can cause uneven expansion, resulting in localized stress on the tube sheets and potentially cracking the welds or loosening the firetube ends.

Preventing Damage

- Always warm up boilers slowly to prevent thermal shock and uneven expansion.

- Keep boilers free from scale buildup to prevent insulation and increased metal temperatures.

- Avoid sudden changes in temperature to prevent thermal shock.

- Take precautions to prevent cold water from entering a hot boiler, especially in steam heating systems.

Boiler Warm-Up

- The rate of warm-up depends on the physical size of the boiler, boiler water content, boiler design, and how long the boiler has been shut down.

- A general rule of thumb is to not increase the boiler water temperature at a rate greater than 55°C per hour to prevent thermal shock and allow for gradual thermal expansion.

- Consult manufacturer specifications for specific warm-up rates.

Monitoring Boiler Warm-Up

- Continually monitor the boiler during warm-up and pressurizing, checking for:

- Symmetrical and turbulent flame pattern

- Signs of poor combustion (flame too rich or too lean)

- "Hot spots" on the metal surface

- Furnace draft pressures

- Fan and feedwater pump operation

- Water level in the boiler

- Low water level alarm and cut-off operation

- Proper operation of the boiler as expected.

Boiler Startup and Warm-Up

- Operators must be aware of the effects of rapid heating on boiler metal and the importance of proper warm-up rates to prevent leaks, premature boiler failure, and ensure safety.

Abnormal Conditions During Startup

- Abnormal conditions may occur during light-off or warm-up period, requiring immediate shutdown and correction of the problem before restarting the boiler.

Normal Cold Start Conditions

- Slight smoking may occur during startup due to incomplete combustion, but should disappear after the boiler is hot.

- Condensation may occur in cold boilers, especially firetube boilers, causing water to run out of the reversing chamber doors, but will stop when the boiler is hot.

Harmful Cold Start Conditions

- Rapid heating can cause thermal shock, uneven expansion, and refractory damage, leading to leakage, premature boiler failure, and costly repairs.

- High firing rates can cause uneven expansion, resulting in localized stress on the tube sheets and potentially cracking the welds or loosening the firetube ends.

Preventing Damage

- Always warm up boilers slowly to prevent thermal shock and uneven expansion.

- Keep boilers free from scale buildup to prevent insulation and increased metal temperatures.

- Avoid sudden changes in temperature to prevent thermal shock.

- Take precautions to prevent cold water from entering a hot boiler, especially in steam heating systems.

Boiler Warm-Up

- The rate of warm-up depends on the physical size of the boiler, boiler water content, boiler design, and how long the boiler has been shut down.

- A general rule of thumb is to not increase the boiler water temperature at a rate greater than 55°C per hour to prevent thermal shock and allow for gradual thermal expansion.

- Consult manufacturer specifications for specific warm-up rates.

Monitoring Boiler Warm-Up

- Continually monitor the boiler during warm-up and pressurizing, checking for:

- Symmetrical and turbulent flame pattern

- Signs of poor combustion (flame too rich or too lean)

- "Hot spots" on the metal surface

- Furnace draft pressures

- Fan and feedwater pump operation

- Water level in the boiler

- Low water level alarm and cut-off operation

- Proper operation of the boiler as expected.

Boiler Startup and Warm-Up

- Operators must be aware of the effects of rapid heating on boiler metal and the importance of proper warm-up rates to prevent leaks, premature boiler failure, and ensure safety.

Abnormal Conditions During Startup

- Abnormal conditions may occur during light-off or warm-up period, requiring immediate shutdown and correction of the problem before restarting the boiler.

Normal Cold Start Conditions

- Slight smoking may occur during startup due to incomplete combustion, but should disappear after the boiler is hot.

- Condensation may occur in cold boilers, especially firetube boilers, causing water to run out of the reversing chamber doors, but will stop when the boiler is hot.

Harmful Cold Start Conditions

- Rapid heating can cause thermal shock, uneven expansion, and refractory damage, leading to leakage, premature boiler failure, and costly repairs.

- High firing rates can cause uneven expansion, resulting in localized stress on the tube sheets and potentially cracking the welds or loosening the firetube ends.

Preventing Damage

- Always warm up boilers slowly to prevent thermal shock and uneven expansion.

- Keep boilers free from scale buildup to prevent insulation and increased metal temperatures.

- Avoid sudden changes in temperature to prevent thermal shock.

- Take precautions to prevent cold water from entering a hot boiler, especially in steam heating systems.

Boiler Warm-Up

- The rate of warm-up depends on the physical size of the boiler, boiler water content, boiler design, and how long the boiler has been shut down.

- A general rule of thumb is to not increase the boiler water temperature at a rate greater than 55°C per hour to prevent thermal shock and allow for gradual thermal expansion.

- Consult manufacturer specifications for specific warm-up rates.

Monitoring Boiler Warm-Up

- Continually monitor the boiler during warm-up and pressurizing, checking for:

- Symmetrical and turbulent flame pattern

- Signs of poor combustion (flame too rich or too lean)

- "Hot spots" on the metal surface

- Furnace draft pressures

- Fan and feedwater pump operation

- Water level in the boiler

- Low water level alarm and cut-off operation

- Proper operation of the boiler as expected.

Boiler Startup and Warm-Up

- Operators must be aware of the effects of rapid heating on boiler metal and the importance of proper warm-up rates to prevent leaks, premature boiler failure, and ensure safety.

Abnormal Conditions During Startup

- Abnormal conditions may occur during light-off or warm-up period, requiring immediate shutdown and correction of the problem before restarting the boiler.

Normal Cold Start Conditions

- Slight smoking may occur during startup due to incomplete combustion, but should disappear after the boiler is hot.

- Condensation may occur in cold boilers, especially firetube boilers, causing water to run out of the reversing chamber doors, but will stop when the boiler is hot.

Harmful Cold Start Conditions

- Rapid heating can cause thermal shock, uneven expansion, and refractory damage, leading to leakage, premature boiler failure, and costly repairs.

- High firing rates can cause uneven expansion, resulting in localized stress on the tube sheets and potentially cracking the welds or loosening the firetube ends.

Preventing Damage

- Always warm up boilers slowly to prevent thermal shock and uneven expansion.

- Keep boilers free from scale buildup to prevent insulation and increased metal temperatures.

- Avoid sudden changes in temperature to prevent thermal shock.

- Take precautions to prevent cold water from entering a hot boiler, especially in steam heating systems.

Boiler Warm-Up

- The rate of warm-up depends on the physical size of the boiler, boiler water content, boiler design, and how long the boiler has been shut down.

- A general rule of thumb is to not increase the boiler water temperature at a rate greater than 55°C per hour to prevent thermal shock and allow for gradual thermal expansion.

- Consult manufacturer specifications for specific warm-up rates.

Monitoring Boiler Warm-Up

- Continually monitor the boiler during warm-up and pressurizing, checking for:

- Symmetrical and turbulent flame pattern

- Signs of poor combustion (flame too rich or too lean)

- "Hot spots" on the metal surface

- Furnace draft pressures

- Fan and feedwater pump operation

- Water level in the boiler

- Low water level alarm and cut-off operation

- Proper operation of the boiler as expected.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.