Podcast

Questions and Answers

What advantage does value stream mapping provide in understanding process efficiency?

What advantage does value stream mapping provide in understanding process efficiency?

- It encourages unnecessary steps in a process.

- It highlights areas with excessive inventory. (correct)

- It solely focuses on the end product's quality.

- It eliminates the need for process flow documentation.

How can value streams contribute to better decision-making in an organization?

How can value streams contribute to better decision-making in an organization?

- By clarifying the flow of information and materials. (correct)

- By reinforcing outdated practices.

- By simplifying complex financial reports.

- By providing a visual representation of all company assets.

Which of the following is NOT a primary benefit of analyzing value streams?

Which of the following is NOT a primary benefit of analyzing value streams?

- Increased operational costs. (correct)

- Enhanced collaboration among teams.

- Improved understanding of customer value.

- Streamlined processes.

What is a key purpose of value stream mapping in lean practices?

What is a key purpose of value stream mapping in lean practices?

Which outcome is likely to result from effective value stream management?

Which outcome is likely to result from effective value stream management?

What is one significant advantage of using value streams in organizational processes?

What is one significant advantage of using value streams in organizational processes?

Which benefit is attributed to value stream mapping in improving workflow?

Which benefit is attributed to value stream mapping in improving workflow?

How does value stream mapping primarily impact customer satisfaction?

How does value stream mapping primarily impact customer satisfaction?

What is a potential outcome of effectively implementing value stream management?

What is a potential outcome of effectively implementing value stream management?

Which of the following is often seen as a primary aim of value stream mapping?

Which of the following is often seen as a primary aim of value stream mapping?

Flashcards

What is a value stream?

What is a value stream?

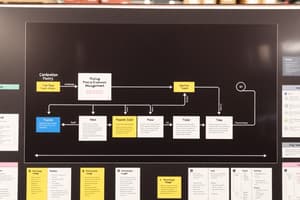

A value stream is a sequence of activities that transforms an input into a valuable output for a customer. Value stream mapping is a visual representation of this process, showing all the steps involved and identifying areas for improvement.

How does value stream mapping help with efficiency?

How does value stream mapping help with efficiency?

Value stream mapping helps to identify and eliminate waste in a process, leading to increased efficiency and productivity.

How can value stream mapping improve understanding?

How can value stream mapping improve understanding?

By visualizing the value stream, organizations can better understand how their processes are working and identify areas for improvement.

How does value stream mapping improve collaboration?

How does value stream mapping improve collaboration?

Signup and view all the flashcards

How can value stream mapping help prioritize efforts?

How can value stream mapping help prioritize efforts?

Signup and view all the flashcards

What's a value stream and why is it mapped?

What's a value stream and why is it mapped?

Signup and view all the flashcards

How does value stream mapping improve efficiency?

How does value stream mapping improve efficiency?

Signup and view all the flashcards

Does value stream mapping promote collaboration?

Does value stream mapping promote collaboration?

Signup and view all the flashcards

How does value stream mapping help focus efforts?

How does value stream mapping help focus efforts?

Signup and view all the flashcards

How does value stream mapping help with understanding processes?

How does value stream mapping help with understanding processes?

Signup and view all the flashcards

Study Notes

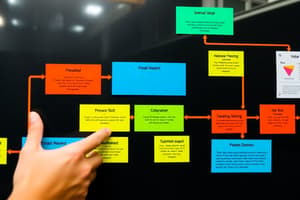

- Value stream mapping (VSM) and value stream management (VSM) methodology improve efficiency by visually identifying and addressing bottlenecks and inefficiencies.

- VSs increase transparency and visibility throughout the production process, aiding stakeholders in identifying problems and inefficiencies more quickly.

- VSM helps streamline processes and reduce lead time.

- It provides improved communication and collaboration across different departments and functions within a company by sharing VSM data, leading to a common goal and focused approach.

- Using VSM in a company can identify and reduce waste in all forms including excess inventory, unnecessary transportation, waiting time, and overproduction.

- VSM focuses on customers and their needs by identifying and enhancing steps needed to fulfill these needs, improving customer satisfaction and loyalty.

- Mapping the value stream allows for identification of problems that hinder the overall goals, often related to bottlenecks and delays. This leads to better problem-solving.

- Value stream mapping enhances decision-making by providing a comprehensive view of the total process. A better understanding of the process leads to better, more informed decisions.

- By identifying areas for improvement or redesigning the current workflow, companies using VSM are better equipped to achieve goals more sustainably.

- Value stream management can reduce costs by optimizing the flow of materials and information and increasing productivity, as well as lowering labor costs by improving efficiency and eliminating unnecessary steps.

- VSM supports planning and execution by allowing for the visualization of the entire process, empowering quicker response times and ability to make course corrections rapidly.

- Organizations using value stream design optimize resource allocation which can improve profitability. VSM allows managers to see what resources are over utilized and others that are lacking.

- Continuous improvement through VSM fosters ongoing analysis and refinement of the value stream, allowing for a quick response to changing circumstances and the integration of new technologies.

- By increasing standardization, VSM improves predictability and consistency in processes, leading to greater production rate and quality of outputs.

- VSM frequently leads to measurable results from process improvement and enhanced team productivity.

- The clarity and visualization delivered through VSM improves communication, fostering a better understanding of the process flow among team members.

- A leaner process, driven by data and feedback from VSM, enhances the ability to meet customer demands and satisfy customer needs.

- Tracking efficiency gains from VSM through data analysis can help identify areas for further optimization, and can also support budgeting, resource planning and future investments.

Potential Benefits Summary

- Improved efficiency: VSM and VSM improve workflow by identifying bottlenecks and inefficiencies.

- Reduced lead time: Streamlining of processes through value stream identification helps reduce time from order to delivery.

- Enhanced communication: VSM helps foster collaboration and common goals across departments.

- Waste reduction: VSM helps identify and reduce waste in areas such as excess inventory, unnecessary transportation, and waiting time.

- Increased customer satisfaction: Improved processes enable fulfillment of customer needs, hence increasing loyalty.

- Better problem-solving: Visualizing the process exposes problems related to bottlenecks and delays, leading to targeted solutions.

- Improved decision-making: A holistic process view delivered by VSM provides data-driven insights.

- Sustainable goal achievement: Value stream methodologies help companies to identify areas of needed improvement to achieve goals more effectively and sustainably.

- Reduced costs: Resource optimization and improved productivity decrease labor costs and optimize materials and information flow.

- Enhanced planning and execution: The visualization of the entire process supports faster response times and rapid course corrections.

- Improved resource allocation: VSM gives a clear view of resource utilization, permitting better allocation to improve profitability.

- Continuous improvement: Ongoing analysis and refinement of the value stream are supported by VSM.

- Increased standardization: Predictability and consistency are improved by increasing standardization via VSM

- Measurable results: Improved process, enhanced team productivity, and better use of data from VSM leads to measureable results

- Data-driven decision-making: Using data analysis from VSM can identify further opportunities for optimization enabling better planning and budgeting.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.