Podcast

Questions and Answers

What type of joint is commonly used for connecting structural parts that do not need to be detached during maintenance?

What type of joint is commonly used for connecting structural parts that do not need to be detached during maintenance?

- Rivet joints (correct)

- Adhesive joints

- Screw joints

- Weld joints

What factors influence the selection of rivets in aircraft structures?

What factors influence the selection of rivets in aircraft structures?

- Manufacturer's brand reputation

- Material type and thickness of parts (correct)

- Color of the rivets

- Cost of rivet manufacturing

In a two-row lap joint, how does the load distribution work?

In a two-row lap joint, how does the load distribution work?

- Every row carries 100% of the load

- Row one carries 60% and row two carries 40%

- The outer row carries 30% and the inner row carries 70%

- Each row carries 50% of the load (correct)

What is the impact of rivet distance on fatigue resistance in riveted joints?

What is the impact of rivet distance on fatigue resistance in riveted joints?

What percentage of the load does the inner row of a three-row joint carry?

What percentage of the load does the inner row of a three-row joint carry?

Flashcards

Rivet joints in structural maintenance

Rivet joints in structural maintenance

Rivet joints are designed for connections that do not require disassembly during maintenance.

Aircraft rivet selection

Aircraft rivet selection

Material type and part thickness guide rivet selection in aircraft structures.

Two-row lap joint load distribution

Two-row lap joint load distribution

Each row in a two-row lap joint bears 50% of the applied load.

Rivet distance and fatigue resistance

Rivet distance and fatigue resistance

Signup and view all the flashcards

Three-row joint inner row load

Three-row joint inner row load

Signup and view all the flashcards

Study Notes

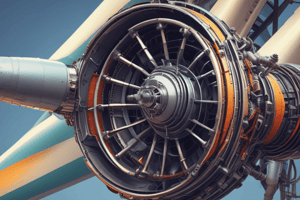

Aircraft Structure

- Aircraft structures are made up of various components manufactured individually and then joined together.

- Common joining methods include adhesives, welds, screws, and rivets.

- Rivet joints are non-detachable and are generally used for structural parts that don't require disassembly during maintenance.

- Factors considered in selecting a rivet include material type, material thickness of the components being joined, and the rivet's shear strength.

Design of Riveted Joints

- Riveted joints are designed so that a single rivet won't fail due to fatigue during normal flight operations.

- Fatigue is more likely to affect the structural element before the rivet under dynamic loads.

- The fatigue resistance of a rivet joint depends on the spacing between rivets and the number of rivet rows.

- In a two-row lap joint, each row carries 50% of the load.

- In a three-row joint, the outer rows carry 40% of the load, while the inner row carries 20% of the load.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.