Podcast

Questions and Answers

What is a major consequence of a damaged control surface on an aircraft?

What is a major consequence of a damaged control surface on an aircraft?

- Increased stability

- Unpredictable reaction (correct)

- Enhanced fuel efficiency

- Improved maneuverability

Which of the following aircraft is a notable example of control surface integration?

Which of the following aircraft is a notable example of control surface integration?

- Airbus A320

- Lockheed SR-71

- Boeing 747 (correct)

- Cessna 152

What is the primary purpose of regular inspections on aircraft control surfaces?

What is the primary purpose of regular inspections on aircraft control surfaces?

- To detect signs of wear, corrosion, or damage (correct)

- To optimize fuel efficiency

- To improve aircraft aesthetics

- To enhance aircraft performance

What is the impact of control surface integration on an aircraft's performance and maneuverability?

What is the impact of control surface integration on an aircraft's performance and maneuverability?

Why is it essential to maintain the integrity of an aircraft's control surfaces?

Why is it essential to maintain the integrity of an aircraft's control surfaces?

What is the result of precise control surface function on an aircraft?

What is the result of precise control surface function on an aircraft?

What is the significance of control surfaces in achieving supersonic speeds?

What is the significance of control surfaces in achieving supersonic speeds?

What is the primary focus of aviation professionals when maintaining an aircraft?

What is the primary focus of aviation professionals when maintaining an aircraft?

Why are control surfaces critical for complex maneuvers?

Why are control surfaces critical for complex maneuvers?

What do regular inspections of control surfaces aim to detect?

What do regular inspections of control surfaces aim to detect?

The Boeing 747's massive ailerons are responsible for its supersonic speeds.

The Boeing 747's massive ailerons are responsible for its supersonic speeds.

Control surfaces are only important for complex maneuvers.

Control surfaces are only important for complex maneuvers.

Regular inspections of control surfaces are only necessary for commercial aircraft.

Regular inspections of control surfaces are only necessary for commercial aircraft.

The integration of control surfaces can have a negative impact on an aircraft's performance.

The integration of control surfaces can have a negative impact on an aircraft's performance.

Aviation professionals focus solely on control surface maintenance when ensuring an aircraft's safe operation.

Aviation professionals focus solely on control surface maintenance when ensuring an aircraft's safe operation.

A damaged control surface can lead to a slight decrease in an aircraft's maneuverability.

A damaged control surface can lead to a slight decrease in an aircraft's maneuverability.

The Concorde's control surfaces were simple and minimalistic in design.

The Concorde's control surfaces were simple and minimalistic in design.

Control surfaces are only critical for takeoff and landing procedures.

Control surfaces are only critical for takeoff and landing procedures.

Regular inspections of control surfaces are a recommended but not mandatory procedure.

Regular inspections of control surfaces are a recommended but not mandatory procedure.

The primary function of control surfaces is to provide structural support to the aircraft.

The primary function of control surfaces is to provide structural support to the aircraft.

What is the significance of understanding the functions and importance of control surfaces, spars, ribs, and stringers for aviation professionals?

What is the significance of understanding the functions and importance of control surfaces, spars, ribs, and stringers for aviation professionals?

How does the integration of control surfaces impact an aircraft's ability to perform complex maneuvers?

How does the integration of control surfaces impact an aircraft's ability to perform complex maneuvers?

What can be the consequence of neglecting regular inspections of control surfaces?

What can be the consequence of neglecting regular inspections of control surfaces?

What is the relationship between control surface integration and an aircraft's fuel efficiency?

What is the relationship between control surface integration and an aircraft's fuel efficiency?

How do control surfaces contribute to an aircraft's overall performance?

How do control surfaces contribute to an aircraft's overall performance?

What is the significance of the Boeing 747's massive ailerons and elaborate flaps system?

What is the significance of the Boeing 747's massive ailerons and elaborate flaps system?

What role do control surfaces play in achieving supersonic speeds?

What role do control surfaces play in achieving supersonic speeds?

What is the primary focus of regular inspections of control surfaces?

What is the primary focus of regular inspections of control surfaces?

How does the integrity of control surfaces impact an aircraft's overall safety?

How does the integrity of control surfaces impact an aircraft's overall safety?

What is the significance of understanding the complex engineering involved in aircraft maintenance?

What is the significance of understanding the complex engineering involved in aircraft maintenance?

Flashcards are hidden until you start studying

Study Notes

Aircraft Structural Elements

- Spars are the main structural members that bear the load and stresses of flight, providing central support to the wing and fuselage.

- They run spanwise, from one tip of the wing to the other, and serve as the primary load-bearing elements during flight.

- Spars must withstand various forces imposed on the wings, such as lift, weight, and stress from maneuvering and turbulence.

Ribs

- Ribs are cross-sectional components that give the wing its aerodynamic shape and distribute lift forces evenly across the surface of the wing.

- They are attached to the spars and are usually perpendicular to them.

- Ribs can be thought of as the 'rungs' in a ladder with the spars being the side rails.

- They support the wing covering and maintain the airfoil shape, critical for generating lift.

Stringers

- Stringers are longitudinal strips that run along the fuselage and wings, contributing to the strength of the skin and preventing it from warping or buckling under stress.

- They provide additional strength and stiffness to the aircraft structure, helping to distribute loads and resist deformation.

- Stringers help maintain the structural integrity of the fuselage and wings by ensuring the skin does not buckle under stress.

Importance of Spars, Ribs, and Stringers

- These elements work in concert to withstand various forces, ensuring the aircraft maintains its structural integrity and aerodynamic efficiency.

- They are made from various materials, including wood, metal, and advanced composites like carbon fiber.

- Precise manufacturing and assembly of these components are crucial to ensure the airframe can handle dynamic loads during flight.

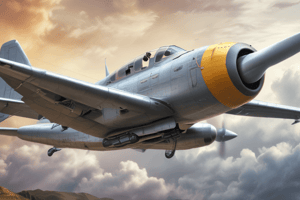

Control Surfaces

- Control surfaces are movable parts of an aircraft's wings or tail that a pilot uses to manage the plane's attitude.

- They are integrated into the wing and tail structures and are essential for the pilot to control the aircraft's direction.

- Primary control surfaces include ailerons, elevators, and rudders, which control roll, pitch, and yaw, respectively.

- Secondary control surfaces include flaps, slats, spoilers, and trim systems, which adjust lift and drag during takeoff, landing, and flight.

Integration of Control Surfaces

- Control surfaces are attached to the rigid framework provided by spars, ribs, and stringers, ensuring precise movement to change airflow around the wing or stabilizer.

- Integration points, where control surfaces meet wings or tail structures, are critical and require meticulous attention to material selection and design.

- Regular inspections are vital to ensure control surface integrity, as any damage or wear can lead to reduced responsiveness or failure.

Aircraft Safety

- Maintaining the integrity of spars, ribs, stringers, and control surfaces is critical for aircraft safety.

- Regular inspections and maintenance are essential to prevent wear, corrosion, or damage that could compromise the aircraft's structural integrity.

- Understanding the functions and significance of these structural components is crucial for aviation professionals to appreciate the complex engineering that goes into maintaining an aircraft and ensuring its safe operation.

Aircraft Structural Elements

- Spars are the main structural members that bear the load and stresses of flight, providing central support to the wing and fuselage.

- They run spanwise, from one tip of the wing to the other, and serve as the primary load-bearing elements during flight.

- Spars must withstand various forces imposed on the wings, such as lift, weight, and stress from maneuvering and turbulence.

Ribs

- Ribs are cross-sectional components that give the wing its aerodynamic shape and distribute lift forces evenly across the surface of the wing.

- They are attached to the spars and are usually perpendicular to them.

- Ribs can be thought of as the 'rungs' in a ladder with the spars being the side rails.

- They support the wing covering and maintain the airfoil shape, critical for generating lift.

Stringers

- Stringers are longitudinal strips that run along the fuselage and wings, contributing to the strength of the skin and preventing it from warping or buckling under stress.

- They provide additional strength and stiffness to the aircraft structure, helping to distribute loads and resist deformation.

- Stringers help maintain the structural integrity of the fuselage and wings by ensuring the skin does not buckle under stress.

Importance of Spars, Ribs, and Stringers

- These elements work in concert to withstand various forces, ensuring the aircraft maintains its structural integrity and aerodynamic efficiency.

- They are made from various materials, including wood, metal, and advanced composites like carbon fiber.

- Precise manufacturing and assembly of these components are crucial to ensure the airframe can handle dynamic loads during flight.

Control Surfaces

- Control surfaces are movable parts of an aircraft's wings or tail that a pilot uses to manage the plane's attitude.

- They are integrated into the wing and tail structures and are essential for the pilot to control the aircraft's direction.

- Primary control surfaces include ailerons, elevators, and rudders, which control roll, pitch, and yaw, respectively.

- Secondary control surfaces include flaps, slats, spoilers, and trim systems, which adjust lift and drag during takeoff, landing, and flight.

Integration of Control Surfaces

- Control surfaces are attached to the rigid framework provided by spars, ribs, and stringers, ensuring precise movement to change airflow around the wing or stabilizer.

- Integration points, where control surfaces meet wings or tail structures, are critical and require meticulous attention to material selection and design.

- Regular inspections are vital to ensure control surface integrity, as any damage or wear can lead to reduced responsiveness or failure.

Aircraft Safety

- Maintaining the integrity of spars, ribs, stringers, and control surfaces is critical for aircraft safety.

- Regular inspections and maintenance are essential to prevent wear, corrosion, or damage that could compromise the aircraft's structural integrity.

- Understanding the functions and significance of these structural components is crucial for aviation professionals to appreciate the complex engineering that goes into maintaining an aircraft and ensuring its safe operation.

Aircraft Structural Elements

- Spars are the main structural members that bear the load and stresses of flight, providing central support to the wing and fuselage.

- They run spanwise, from one tip of the wing to the other, and serve as the primary load-bearing elements during flight.

- Spars must withstand various forces imposed on the wings, such as lift, weight, and stress from maneuvering and turbulence.

Ribs

- Ribs are cross-sectional components that give the wing its aerodynamic shape and distribute lift forces evenly across the surface of the wing.

- They are attached to the spars and are usually perpendicular to them.

- Ribs can be thought of as the 'rungs' in a ladder with the spars being the side rails.

- They support the wing covering and maintain the airfoil shape, critical for generating lift.

Stringers

- Stringers are longitudinal strips that run along the fuselage and wings, contributing to the strength of the skin and preventing it from warping or buckling under stress.

- They provide additional strength and stiffness to the aircraft structure, helping to distribute loads and resist deformation.

- Stringers help maintain the structural integrity of the fuselage and wings by ensuring the skin does not buckle under stress.

Importance of Spars, Ribs, and Stringers

- These elements work in concert to withstand various forces, ensuring the aircraft maintains its structural integrity and aerodynamic efficiency.

- They are made from various materials, including wood, metal, and advanced composites like carbon fiber.

- Precise manufacturing and assembly of these components are crucial to ensure the airframe can handle dynamic loads during flight.

Control Surfaces

- Control surfaces are movable parts of an aircraft's wings or tail that a pilot uses to manage the plane's attitude.

- They are integrated into the wing and tail structures and are essential for the pilot to control the aircraft's direction.

- Primary control surfaces include ailerons, elevators, and rudders, which control roll, pitch, and yaw, respectively.

- Secondary control surfaces include flaps, slats, spoilers, and trim systems, which adjust lift and drag during takeoff, landing, and flight.

Integration of Control Surfaces

- Control surfaces are attached to the rigid framework provided by spars, ribs, and stringers, ensuring precise movement to change airflow around the wing or stabilizer.

- Integration points, where control surfaces meet wings or tail structures, are critical and require meticulous attention to material selection and design.

- Regular inspections are vital to ensure control surface integrity, as any damage or wear can lead to reduced responsiveness or failure.

Aircraft Safety

- Maintaining the integrity of spars, ribs, stringers, and control surfaces is critical for aircraft safety.

- Regular inspections and maintenance are essential to prevent wear, corrosion, or damage that could compromise the aircraft's structural integrity.

- Understanding the functions and significance of these structural components is crucial for aviation professionals to appreciate the complex engineering that goes into maintaining an aircraft and ensuring its safe operation.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.