Podcast

Questions and Answers

What is the primary function of a gas turbine engine indication system?

What is the primary function of a gas turbine engine indication system?

Which of the following sensors is commonly used to measure engine temperature?

Which of the following sensors is commonly used to measure engine temperature?

What is the primary function of indicators in a gas turbine engine indication system?

What is the primary function of indicators in a gas turbine engine indication system?

What type of display is commonly used in a gas turbine engine indication system?

What type of display is commonly used in a gas turbine engine indication system?

Signup and view all the answers

What is the primary function of the computer in a gas turbine engine indication system?

What is the primary function of the computer in a gas turbine engine indication system?

Signup and view all the answers

What is the primary function of the Engine Performance Monitoring system?

What is the primary function of the Engine Performance Monitoring system?

Signup and view all the answers

What is the benefit of the gas turbine engine indication system in terms of safety?

What is the benefit of the gas turbine engine indication system in terms of safety?

Signup and view all the answers

What is the function of the Warning and Alert Systems?

What is the function of the Warning and Alert Systems?

Signup and view all the answers

What is the purpose of the Diagnostic Capabilities component?

What is the purpose of the Diagnostic Capabilities component?

Signup and view all the answers

What is the benefit of the gas turbine engine indication system in terms of maintenance?

What is the benefit of the gas turbine engine indication system in terms of maintenance?

Signup and view all the answers

What is the primary component of the gas turbine engine indication system?

What is the primary component of the gas turbine engine indication system?

Signup and view all the answers

Study Notes

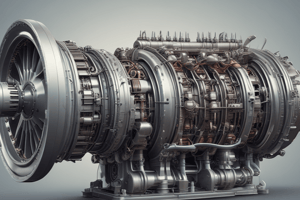

Gas Turbine Engine Indication System

A gas turbine engine indication system is a critical component of an aircraft's engine management system. It provides pilots and maintenance personnel with essential information about the engine's performance and health.

Key Components

-

Sensors: Measure various engine parameters such as temperature, pressure, speed, and vibration. Common sensors include:

- Thermocouples (temperature)

- Pressure sensors (fuel, oil, and compressor)

- Tachometers (engine speed)

- Accelerometers (vibration)

-

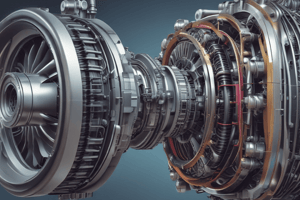

Indicators: Display sensor data to the pilot in a clear and concise manner. Common indicators include:

- Engine Instruments (e.g., EGT, N1, N2, Fuel Flow)

- Warning lights and caution lights

- Digital displays (e.g., LCD, LED)

-

Computer: Processes sensor data and provides calculations, warnings, and alerts. Common computers include:

- Electronic Engine Control (EEC)

- Full Authority Digital Engine Control (FADEC)

Functions

-

Engine Performance Monitoring: Provides real-time data on engine performance, including:

- Engine speed (RPM)

- Temperature (EGT, TIT, etc.)

- Fuel flow and consumption

- Oil pressure and temperature

-

Warning and Alert Systems: Generates alerts and warnings for abnormal engine conditions, including:

- Over-temperature

- Over-speed

- Low oil pressure

- Fuel leaks

-

Diagnostic Capabilities: Allows maintenance personnel to diagnose engine faults and perform troubleshooting, including:

- Fault codes and messages

- Data logging and trend analysis

Benefits

- Improved Safety: Enhances pilot awareness and response to engine anomalies, reducing the risk of engine failure or damage.

- Increased Efficiency: Optimizes engine performance, reducing fuel consumption and emissions.

- Reduced Maintenance: Enables predictive maintenance, reducing downtime and maintenance costs.

Summary

The gas turbine engine indication system is a critical component of an aircraft's engine management system, providing pilots and maintenance personnel with essential information about engine performance and health. Its key components, including sensors, indicators, and computers, work together to monitor engine performance, detect abnormalities, and facilitate diagnostic and maintenance activities.

Gas Turbine Engine Indication System

- Critical component of an aircraft's engine management system, providing essential information about engine performance and health.

Key Components

- Sensors: • Measure various engine parameters such as temperature, pressure, speed, and vibration. • Include thermocouples, pressure sensors, tachometers, and accelerometers.

- Indicators: • Display sensor data to the pilot in a clear and concise manner. • Include engine instruments, warning lights, caution lights, and digital displays.

- Computer: • Processes sensor data and provides calculations, warnings, and alerts. • Includes Electronic Engine Control (EEC) and Full Authority Digital Engine Control (FADEC).

Functions

Engine Performance Monitoring

- Provides real-time data on engine performance, including: • Engine speed (RPM) • Temperature (EGT, TIT, etc.) • Fuel flow and consumption • Oil pressure and temperature

Warning and Alert Systems

- Generates alerts and warnings for abnormal engine conditions, including: • Over-temperature • Over-speed • Low oil pressure • Fuel leaks

Diagnostic Capabilities

- Allows maintenance personnel to diagnose engine faults and perform troubleshooting, including: • Fault codes and messages • Data logging and trend analysis

Benefits

- Improved Safety: Enhances pilot awareness and response to engine anomalies, reducing the risk of engine failure or damage.

- Increased Efficiency: Optimizes engine performance, reducing fuel consumption and emissions.

- Reduced Maintenance: Enables predictive maintenance, reducing downtime and maintenance costs.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Learn about the critical components of a gas turbine engine indication system, including sensors that measure engine parameters and provide essential information to pilots and maintenance personnel.