Podcast

Questions and Answers

What is the factory default voltage setting for the 3D printer?

What is the factory default voltage setting for the 3D printer?

- 220V (correct)

- 130V

- 240V

- 110V

Filament should be inserted into the hotend before preheating.

Filament should be inserted into the hotend before preheating.

False (B)

What temperature should the filament reach for proper flow during printing?

What temperature should the filament reach for proper flow during printing?

180-190°C

The main board wiring diagram is shown in Fig. ______.

The main board wiring diagram is shown in Fig. ______.

Match the following components with their corresponding steps:

Match the following components with their corresponding steps:

What is suggested to do with the bent tip of the filament before installation?

What is suggested to do with the bent tip of the filament before installation?

It is important to ensure the filament reel is tangled before installation.

It is important to ensure the filament reel is tangled before installation.

What action should be taken if resistance is felt during filament installation?

What action should be taken if resistance is felt during filament installation?

What should be adjusted if the nozzle is lower than the platform?

What should be adjusted if the nozzle is lower than the platform?

What is the recommended printing speed range for 3D printing?

What is the recommended printing speed range for 3D printing?

The Cura software allows loading files with the extension 'TXT'.

The Cura software allows loading files with the extension 'TXT'.

What is the purpose of ensuring the heat bed is horizontal?

What is the purpose of ensuring the heat bed is horizontal?

The nozzle size for the 3D printer is 1.75mm.

The nozzle size for the 3D printer is 1.75mm.

To clear the platform in Cura, click on 'File' and then select '__________'.

To clear the platform in Cura, click on 'File' and then select '__________'.

What type of driver needs to be installed for online printing?

What type of driver needs to be installed for online printing?

The diameter of the selected wire is ______.

The diameter of the selected wire is ______.

Match the actions in Cura with their corresponding descriptions:

Match the actions in Cura with their corresponding descriptions:

What is the function of the 'Lay Flat' option in Cura?

What is the function of the 'Lay Flat' option in Cura?

What should be the only characters used in the file name for GCode?

What should be the only characters used in the file name for GCode?

Match the following print settings with their descriptions:

Match the following print settings with their descriptions:

You need to adjust the Z adjustable nut only once during leveling.

You need to adjust the Z adjustable nut only once during leveling.

What is the first step to manipulate a 3D model in Cura?

What is the first step to manipulate a 3D model in Cura?

You can view the model in 'Layers' mode to check for skipped layers.

You can view the model in 'Layers' mode to check for skipped layers.

What should happen when the temperature reaches the target during printing?

What should happen when the temperature reaches the target during printing?

What could be a cause of stripes or bulge on the surface in 3D printing?

What could be a cause of stripes or bulge on the surface in 3D printing?

A clogged hot end can lead to uneven extruding.

A clogged hot end can lead to uneven extruding.

What should you check if your print stops halfway through?

What should you check if your print stops halfway through?

If the quality of filament is poor, it may cause __________ on the surface.

If the quality of filament is poor, it may cause __________ on the surface.

Match the following issues with their potential causes:

Match the following issues with their potential causes:

Which of the following could lead to a file not printing?

Which of the following could lead to a file not printing?

Temperature fluctuations have no impact on the quality of prints.

Temperature fluctuations have no impact on the quality of prints.

What is a common cause of motor shaking or abnormal sound?

What is a common cause of motor shaking or abnormal sound?

What could be a reason for gaps or hollows on the top layer of a 3D print?

What could be a reason for gaps or hollows on the top layer of a 3D print?

A high printing temperature could contribute to printing model melting.

A high printing temperature could contribute to printing model melting.

What should be checked if the print head is moving too fast?

What should be checked if the print head is moving too fast?

The __________ value has been set too low in the slicing software, leading to insufficient filling of the model.

The __________ value has been set too low in the slicing software, leading to insufficient filling of the model.

Match the problems with their solutions:

Match the problems with their solutions:

What could cause wire drawing during printing?

What could cause wire drawing during printing?

Too high a printing speed can lead to gaps between layers.

Too high a printing speed can lead to gaps between layers.

What happens if the filament diameter is incorrect?

What happens if the filament diameter is incorrect?

Which type of laser is primarily used for cutting, boring, and engraving?

Which type of laser is primarily used for cutting, boring, and engraving?

CO2 lasers have a higher electrical-to-optical conversion efficiency compared to Nd:YAG lasers.

CO2 lasers have a higher electrical-to-optical conversion efficiency compared to Nd:YAG lasers.

What is the typical emission wavelength of CO2 lasers?

What is the typical emission wavelength of CO2 lasers?

The __________ of a laser beam can be varied to cut or engrave different materials.

The __________ of a laser beam can be varied to cut or engrave different materials.

Which laser type is ideal for operations requiring very high power?

Which laser type is ideal for operations requiring very high power?

Match the laser type with its primary application:

Match the laser type with its primary application:

What future improvement could be implemented in laser cutting machines according to the content?

What future improvement could be implemented in laser cutting machines according to the content?

Laser engraving using CNC-controlled lasers requires a resistive mask.

Laser engraving using CNC-controlled lasers requires a resistive mask.

Flashcards are hidden until you start studying

Study Notes

Safety Instructions

- Always follow the manufacturer's safety guidelines.

- Ensure adequate ventilation while using the 3D printer.

- Avoid touching hot surfaces.

- Wear safety goggles to protect your eyes from debris.

- Keep flammable materials away from the printer.

Technical Specification

- Printing Parameters:

- Temperature Parameters: Preheating required before filament insertion.

- Software Parameters: Use Cura software for slicing and Gcode generation.

- Electrical Parameters: Voltage selection switch for 110V/220V operation.

- Physical Parameters: Requires 1.75mm filament and a 0.4mm nozzle.

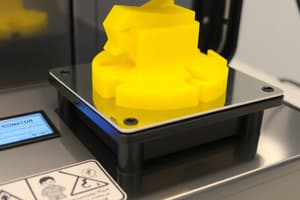

- Part List: Refer to the provided image for components and assembly diagrams.

Product Overview

- Menu Directory:

- Home Menu: General settings and diagnostics.

- APPCATION Menu: Access to applications like printing and leveling.

- SYSTEM Menu: System configuration options.

- PRINT Menu: Print settings and file selection.

Assembly Instructions

- Component parts should be assembled according to provided diagrams.

- Ensure proper wiring connections based on the provided diagram (Figure 10).

- Select the correct voltage setting for your region.

Filament Installation

- Preheat the hotend before inserting filament.

- Trim off any bent tip.

- Rotate the filament during insertion if resistance occurs.

- Ensure the filament reel is free from tangles.

Leveling Instructions

- Level the platform by adjusting the 4 nuts under the bed.

- Adjust the Z axis to ensure the nozzle is at a suitable height.

- Use the "LEVELING" function in the APPCATION menu to test and verify.

Cura Instructions

- Install Cura software for slicing and gcode generation.

- Configure Cura settings based on your printer's specifications.

- Adjust basic and advanced settings according to your needs.

- Use the right plugins for optimal printing performance.

Online Printing Instructions

- Install the CH341SER driver to enable online printing via USB connection.

- In Cura, choose the correct COM port corresponding to your printer.

- Print online by selecting the "Print" option in the Cura software.

Troubleshooting

- Common issues and solutions:

- Filament clogging: Clean or replace the nozzle and nozzle throat.

- Layer shifting: Check belts, driving wheels, and tighten all screws.

- Gaps or hollow: Increase the layer count, adjust fill value, and ensure sufficient filament flow.

- Rough angles: Increase cooling, lower printing speed, or adjust slicing path.

- Wrinkles: Ensure filament quality, stable temperature, and proper Z axis positioning.

- Motor shaking: Check motor cables and ensure proper end stop triggering.

- SD card failure: Verify SD card functionality and formatting.

- Print stopped halfway: Check for Gcode corruption.

- Touch screen unresponsive: Ensure proper connection cables and inspect for damage.

Lasers

- Lasers are increasingly used in industrial machining because they produce high precision and quality products with minimal heat-affected-zone.

- Laser-machined work-pieces have superior dimensional tolerances and accuracy.

- Most laser cutting machines are CNC-controlled, ensuring quality and timely outputs.

- Laser beam intensity can be varied to cut, engrave, or mark various materials.

- Laser engraving using CNC systems does not require a resistive mask. The laser beam path is precisely controlled by the CNC, allowing for complex and intricate designs.

CO2 Lasers

- CO2 lasers are most commonly used for material processing.

- They are produced by passing an electric discharge through a gas mixture of carbon dioxide, nitrogen, and helium.

- CO2 lasers emit infrared light with a typical wavelength of 10.6 μm, but lower wavelengths are used for processing certain polymers.

- CO2 lasers offer a high average power output, ranging from a few Watts up to 50 kW.

- Applications include automotive manufacturing, steel parts production, and marking, annealing, engraving, or welding metals, plastics, or wood.

- CO2 lasers offer excellent beam quality but lower electrical-to-optical conversion efficiency.

Future Scope of Lasers

- Integration of design software like Solidworks to provide a GUI and automatically generate part programs from drafted profiles.

- Increasing the working area of laser cutting machines.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.