Podcast

Questions and Answers

Which of the following best describes the 'build area' in 3D printing?

Which of the following best describes the 'build area' in 3D printing?

- The area on the print bed where the first layer adheres.

- The area surrounding the 3D printer required for operation.

- The physical space the 3D printer occupies.

- The maximum volume of an object that can be printed. (correct)

What is the primary difference between a Bowden extruder and a Direct Drive extruder?

What is the primary difference between a Bowden extruder and a Direct Drive extruder?

- Bowden extruders require more maintenance compared to Direct Drive extruders.

- Bowden extruders are used for flexible filaments, while Direct Drive extruders are used for rigid filaments.

- Bowden extruders provide finer control over extrusion than Direct Drive extruders.

- Bowden extruders are physically separated from the hot end, while Direct Drive extruders mount directly on top of the hot end. (correct)

What advantage does a smaller nozzle size generally offer in 3D printing?

What advantage does a smaller nozzle size generally offer in 3D printing?

- Less need for support structures when printing overhangs.

- Faster printing speeds due to reduced material usage.

- Enhanced ability to print intricate details and smoother finishes. (correct)

- Improved first layer adhesion on various print bed surfaces.

Why is active cooling typically beneficial in 3D printing?

Why is active cooling typically beneficial in 3D printing?

What temperature range is typically expected for a heated bed in a 3D printer?

What temperature range is typically expected for a heated bed in a 3D printer?

Why might a user choose to use multiple extruders in a 3D printer?

Why might a user choose to use multiple extruders in a 3D printer?

What is the main function of the hot end in a 3D printer?

What is the main function of the hot end in a 3D printer?

Which factor is LEAST important to consider when selecting a hot end for a 3D printer?

Which factor is LEAST important to consider when selecting a hot end for a 3D printer?

How might using a larger nozzle size affect a 3D print?

How might using a larger nozzle size affect a 3D print?

What role does G-code play in the operation of a 3D printer with an LCD display?

What role does G-code play in the operation of a 3D printer with an LCD display?

If a 3D printer has a build area specified as 200mm x 200mm x 300mm, what does the '300mm' dimension represent?

If a 3D printer has a build area specified as 200mm x 200mm x 300mm, what does the '300mm' dimension represent?

Which of the following is a primary benefit of using an all-metal hot end over a PEEK-based hot end?

Which of the following is a primary benefit of using an all-metal hot end over a PEEK-based hot end?

What is the most common filament diameter used in FDM 3D printers, according to the information?

What is the most common filament diameter used in FDM 3D printers, according to the information?

Which bed surface is best suited when printing with common materials and needs no solvents or glue?

Which bed surface is best suited when printing with common materials and needs no solvents or glue?

What is the primary reason for using a heated bed in 3D printing?

What is the primary reason for using a heated bed in 3D printing?

Which of the following is a potential drawback of using a Bowden extruder setup?

Which of the following is a potential drawback of using a Bowden extruder setup?

How does a cooling fan enhance the capabilities of a 3D printer?

How does a cooling fan enhance the capabilities of a 3D printer?

What is the primary function of a 3D printer's extruder?

What is the primary function of a 3D printer's extruder?

Which factor is most important when 3D printing with multiple extruders?

Which factor is most important when 3D printing with multiple extruders?

How does the nozzle of a 3D printer influence the final print quality?

How does the nozzle of a 3D printer influence the final print quality?

What is a key consideration when using blue tape (painter's tape) as a print bed surface?

What is a key consideration when using blue tape (painter's tape) as a print bed surface?

A user is experiencing warping issues with ABS filament. What adjustment should they make to their printer settings or setup?

A user is experiencing warping issues with ABS filament. What adjustment should they make to their printer settings or setup?

What advantage does active cooling provide when printing overhangs?

What advantage does active cooling provide when printing overhangs?

What should a user consider to avoid jamming when using a smaller nozzle?

What should a user consider to avoid jamming when using a smaller nozzle?

What is the primary function of the LCD display on a 3D printer?

What is the primary function of the LCD display on a 3D printer?

In what circumstances is a Direct Drive extruder generally preferred over a Bowden extruder?

In what circumstances is a Direct Drive extruder generally preferred over a Bowden extruder?

What is the best practice regarding the nozzle sizes?

What is the best practice regarding the nozzle sizes?

What is the primary consideration when choosing a 3D printer based on the 'Build Area' specification?

What is the primary consideration when choosing a 3D printer based on the 'Build Area' specification?

Flashcards

What is the 'Build Area'?

What is the 'Build Area'?

The maximum size of an object that can be created with a 3D printer, measured in XYZ dimensions.

What is Filament Diameter?

What is Filament Diameter?

The thickness of the filament used in FDM 3D printers, typically 1.75mm or 3mm.

What is the Hot End?

What is the Hot End?

The part of the 3D printer where plastic is melted and extruded in layers.

What is Maximum Printing Temperature?

What is Maximum Printing Temperature?

Signup and view all the flashcards

What is the Nozzle?

What is the Nozzle?

Signup and view all the flashcards

What are the benefits of Smaller Nozzle Size:

What are the benefits of Smaller Nozzle Size:

Signup and view all the flashcards

What are the benefits of Bigger Nozzle Size:

What are the benefits of Bigger Nozzle Size:

Signup and view all the flashcards

What is the Extruder?

What is the Extruder?

Signup and view all the flashcards

What is a Direct Extruder?

What is a Direct Extruder?

Signup and view all the flashcards

What is Bowden Extruder?

What is Bowden Extruder?

Signup and view all the flashcards

What is Cooling Fan?

What is Cooling Fan?

Signup and view all the flashcards

What is a Heated Bed?

What is a Heated Bed?

Signup and view all the flashcards

What is Print Bed Surface?

What is Print Bed Surface?

Signup and view all the flashcards

What is LCD Display?

What is LCD Display?

Signup and view all the flashcards

What are Multiple Extruders?

What are Multiple Extruders?

Signup and view all the flashcards

Study Notes

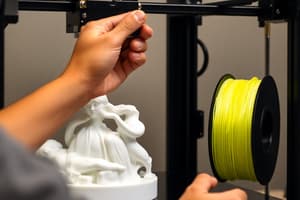

Main Components of 3D Printers

- 3D printers include key components such as print display, extruder, hot end, cooling fan, 3D print, filament, and print bed.

Build Area

- Build area denotes the maximum object size a 3D printer can create, measured in XYZ dimensions.

- An example of build area size is 8 inches wide (X) by 8 inches deep (Y) by 10 inches high, represented as 8x8x10 inches.

- Large or complex print jobs can be divided into smaller parts for printing and combined afterward.

Filament Diameter

- FDM 3D printers typically use 1.75mm or 3mm filament diameter; the trend favors 1.75mm.

- Machines with Bolden Extruder setups work better with 1.75mm filament.

- 3D printers with Direct Drive setups mainly use 3mm filament.

- Sticking to one filament size is more practical when owning different brands of FDM 3D printers.

Hot End

- The hot end is one of the most important parts of a 3D printer, used for melting plastic and extruding it in tiny layers.

- Important factors for a hot end includes maximum printing temperature, nozzle size, options to change it, and active cooling.

Hot End Types

- Old hot ends were PEEK based, printed one or two materials, and had a temperature limit of about 230°C

- Newer hot ends can use a variety of thermoplastics.

- All metal hot ends can print with available materials, including Nylon, PET, and Polycarbonate.

- All metal hot ends extrude at temperatures above 240°C and have a maximum temperature of 320°C.

- Hexagon all metal hot ends feature active cooling to isolate the melt zone, resulting in cleaner prints due to better retraction and less oozing.

- All metal hot ends have fewer parts, are almost jam-free, and are easy to clean, requiring very little maintenance except when changing filaments.

Nozzle

- The nozzle is the tip of the hot end where the plastic exits, and it needs to be exchangeable.

- Nozzle sizes range from 0.25mm to 0.75mm, with 0.5mm being the most common.

- Changing the nozzle size should be based on design and desired results.

Smaller Nozzle Size

- Smoother Finish: Smaller nozzles produce thinner lines and smaller layer heights for a superior part finish.

- More ridge parts: More, thinner lines create more layers, which can result in the part having stronger bonds.

- More Accurate Prints: Accuracy depends on printer calibration/slicing software, a smaller nozzle size can result in dimensions that are closer to perfect.

- More Detailed Prints: Downgrading nozzle size helps emphasize small features in a design.

Bigger Nozzle Size

- Faster printing, bigger nozzle results in thicker strings, reduces layers, and decreases printing time.

- Better first layer adhesion is due to thicker strings leading to more surface area for the plastic to adhere to.

- Less supports may be needed as bigger nozzles handle overhangs because the ratio between layer height and the extrusion width is greater.

- Better reliability comes due to faster printing and more room for error, resulting in a higher success rate with filaments that have some variations in diameter.

Extruder

- The extruder feeds filament to the hot end, there are two different types of extruders.

Direct Extruder

- Filament is fed from the motor spindle to the hot end, that's mounted on top, this allows finer control over extrusion and is easier to work with.

Bowden Extruder

- The filament is fed form a distance to the hot end, the filament has to travel through a tube.

- Bowden extruders reduce weight, allows for faster movement, and reduces vibrations.

- Bowden extruders should produce more accurate, faster prints

- Bowden extruders require better extrusion and retraction calibration

- It's harder to print certain filaments like Flexible, due to the distance it's oozing more, because the retraction is not as effective.

Cooling Fan

- Cooling is beneficial for most 3D prints, all 3D printing materials require active cooling.

- Cooling fans improve overhanging features, will crisp the edges, and good bridging capabilities.

- Fans vary in size (25mm to 40mm) and design, with some blowing at the mid hot end area and others focused at the nozzle tip.

Heated Bed

- Heated beds are required for high temperature, such as ABS, HIPS, Polycarbonate, and Nylon.

- Heated beds keep plastic warm during printing and prevent warping.

- Heated beds ensure better adhesion between layers for printed parts, crucial for the first layer.

- The temperature usually will be between 40°C to 110°C

- Unheated beds are compatible with PLA based plastics and TPUs

- Beds are covered with PEI, PET or Painters blue tape to which the material adhere.

Print Bed Surface

- The print bed surface helps the print to adhere to the print bed during printing.

- Blue tape works with PLA and NinjaFlex, but better alternatives are available.

- PET 3M tape needs a GOO GLUE for the prints to adhere (GOO GLUE is a SOLVENT OF ACETONE AND ABS PLASTIC), PET tape is easy to replace but more expensive.

- PEI 3M tape works without solvents or glue; has a longer lifespan than most print surfaces.

LCD Display

- Using the LCD display allows you to 3D print without a PC, using software such as Cura.

- The display allows more efficient space usage and is used in the majority of print jobs.

- An SD card is required to read the G-code instructions,

Multiple Extruders

- Multiple extruders allow printing in multiple colors/materials by assigning each extruder a specific color/material.

- The benefit of multiple extruders is setting support structures with a different material that can be dissolved in water.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.