Podcast

Questions and Answers

What is the factory default voltage setting for the 3D printer?

What is the factory default voltage setting for the 3D printer?

- 110V

- 240V

- 230V

- 220V (correct)

Filament should be inserted into the hotend without preheating it first.

Filament should be inserted into the hotend without preheating it first.

False (B)

What must be checked before installing the filament into the hotend?

What must be checked before installing the filament into the hotend?

The printer must be preheated.

To avoid resistance during filament installation, it is suggested to cut off the bent tip and __________.

To avoid resistance during filament installation, it is suggested to cut off the bent tip and __________.

Match the assembly steps with their descriptions:

Match the assembly steps with their descriptions:

At what temperature should the filament begin to flow through the hotend?

At what temperature should the filament begin to flow through the hotend?

The main board wiring diagram assists in connecting the correct components.

The main board wiring diagram assists in connecting the correct components.

What tool can be used to remove extruded filament at the nozzle tip before printing?

What tool can be used to remove extruded filament at the nozzle tip before printing?

What is the first step in leveling the platform according to the instructions?

What is the first step in leveling the platform according to the instructions?

The nozzle should be adjusted by tightening if it is lower than the platform.

The nozzle should be adjusted by tightening if it is lower than the platform.

What file types can be loaded into Cura?

What file types can be loaded into Cura?

The __________ option is important to ensure the flat portion of the model is securely attached to the platform.

The __________ option is important to ensure the flat portion of the model is securely attached to the platform.

Match the following terms with their definitions:

Match the following terms with their definitions:

What is the function of the 'Clear platform' option in Cura?

What is the function of the 'Clear platform' option in Cura?

You can change the viewing angle in Cura by left-clicking the model and dragging the mouse.

You can change the viewing angle in Cura by left-clicking the model and dragging the mouse.

What should be done after rotating a model in Cura?

What should be done after rotating a model in Cura?

What is the recommended printing speed for optimal accuracy?

What is the recommended printing speed for optimal accuracy?

The nozzle diameter for printing is 0.8mm.

The nozzle diameter for printing is 0.8mm.

What is the diameter of the wire selected for printing?

What is the diameter of the wire selected for printing?

To disable uniform scaling in the model, click the ______ in the scaling window.

To disable uniform scaling in the model, click the ______ in the scaling window.

Match the following components with their descriptions:

Match the following components with their descriptions:

Which of the following file name restrictions must be followed in Cura?

Which of the following file name restrictions must be followed in Cura?

The CH341SER driver must be installed for USB connection in online printing.

The CH341SER driver must be installed for USB connection in online printing.

What should be done after clicking 'Print...' in Cura?

What should be done after clicking 'Print...' in Cura?

Flashcards are hidden until you start studying

Study Notes

Safety Instructions

- Safety instructions are included in the document

Technical Specification

- Printing parameters, temperature parameters, software parameters, electrical parameters, and physical parameters are listed

Printing Parameters

- Printing speed is recommended to be 50-60mm/s, but not faster to ensure accuracy

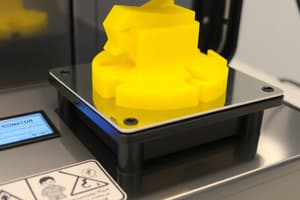

Assembly Instructions

- Figure 1 shows the assembly steps for components

- Figure 6 shows the installation of the top aluminum part

- Figures 8 and 9 illustrate additional assembly steps

- The main board wiring diagram is shown in Figure 10

- The correct voltage mode should be selected according to local voltage ratings, with a switch on the power supply inside the base box (factory default is 220V)

Filament Installation

- Filament should only be inserted into the hotend after it has been preheated

- Bent filament tips should be cut off

- Filament should be rotated if resistance is felt during installation

- Filament should be free of ties or tangles

Leveling Instructions

- Manually insert filament through the Teflon tubing into the hotend after the temperature rises

- Filament should flow through at temperatures above 180-190°C, otherwise, it was not properly inserted

- Customers can remove extruded filament from the nozzle tip with tweezers

- First-layer test prints might result in three different outcomes, shown in Figures 17 and 18 (these figures are not present in the text)

Additional Leveling Steps

- Adjust the four nuts under the platform to ensure a suitable distance between the support plate and the heat bed

- Loosen the Z adjustable nut by X mm if the nozzle is lower than the platform, and tighten it by Y mm if the nozzle is too high (X and Y are defined by the distance between the nozzle and the platform)

- Multiple adjustments might be required

- On the Home menu, click "APPCATION" -> "LEVELING" and then "home" to verify the results

Cura Instructions

- Cura can be downloaded and installed from the provided link (link is not present in the text)

- Machine settings can be adjusted in the Cura software, including basic and advanced options

- Plugins can be added, including Start/End-GCode

- Load 3D models into Cura by selecting "File" -> "Load model file...". Supported file types are STL, OBJ, DAE, and AMF

- Models can be manipulated in Cura by zooming, rotating, changing viewing angle, changing position, and scaling

- There are different viewing modes in Cura, including "Layers" mode to view the toolpath and check for skipped layers or gaps

- Save the GCode file in Cura and confirm that all slices have been included in "Layers view"

- Use only English letters, underscores, and spaces when naming the GCode file

Cura Settings

- Wire diameter is 1.75mm

- Nozzle size is 0.4mm

- Recommended printing speed is 50-60mm/s

- Shell print speed should be reduced to improve flatness of the model surface

Online Printing Instructions

- Install the CH341SER driver from the SD card (Programming software and Driver -> CH341SER)

- Connect the 3D printer to the PC via USB cable

- After the driver installation, a COMx should appear in the Ports section of the Device Manager

- Despite proper installation, an incorrect COMx might still appear in the Ports section

- Configure Cura settings for online printing

- Print online in Cura via the USB connection by selecting "File" -> "Print..."

- After clicking "Print...", a printing window will appear, showing the printing process and allowing temperature control

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.