Podcast

Questions and Answers

Which of the following best describes the primary function of a lathe?

Which of the following best describes the primary function of a lathe?

- To weld together metal pieces using high temperatures

- To remove metal from a cylindrical workpiece to achieve a desired size and shape (correct)

- To mold metal into complex shapes using heat and pressure

- To measure the dimensions of metal objects with high precision

A 'live centre' in a metal lathe setup is simply a metal shaft with a point.

A 'live centre' in a metal lathe setup is simply a metal shaft with a point.

False (B)

What is the purpose of the chuck key?

What is the purpose of the chuck key?

To tighten or loosen the chuck

Before any turning takes place, it is common practice to check that the point of the lathe tool is ______.

Before any turning takes place, it is common practice to check that the point of the lathe tool is ______.

What should you do with the guard during the operation of the lathe?

What should you do with the guard during the operation of the lathe?

The three jaws chuck allows each jaw to be adjusted independently, making it suitable for holding irregularly shaped or non-cylindrical workpieces.

The three jaws chuck allows each jaw to be adjusted independently, making it suitable for holding irregularly shaped or non-cylindrical workpieces.

What should the operator wear when using the lathe?

What should the operator wear when using the lathe?

A ______ calliper is used to measure the outside diameter of the piece.

A ______ calliper is used to measure the outside diameter of the piece.

Why should the metal being machined extrude from the chuck a short distance?

Why should the metal being machined extrude from the chuck a short distance?

What is attached to the tailstock during drilling activities?

What is attached to the tailstock during drilling activities?

Flashcards

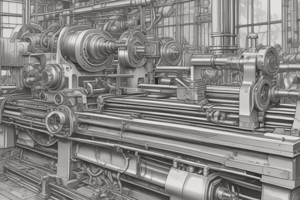

What is a Lathe?

What is a Lathe?

The lathe is a machine that removes metal from a cylindrical metal piece to achieve the desired size and shape.

What is a Chuck?

What is a Chuck?

A device used to securely hold the workpiece in place during machining.

3-Jaw vs. 4-Jaw Chuck

3-Jaw vs. 4-Jaw Chuck

Three jaws move simultaneously for quick centering, whereas four jaws adjust independently for irregular shapes.

What is a Live Center?

What is a Live Center?

Signup and view all the flashcards

What is a Dead Center?

What is a Dead Center?

Signup and view all the flashcards

What is a Chuck Key?

What is a Chuck Key?

Signup and view all the flashcards

What is Parallel Turning?

What is Parallel Turning?

Signup and view all the flashcards

What is Taper Turning?

What is Taper Turning?

Signup and view all the flashcards

What is a Knurling Tool’s purpose?

What is a Knurling Tool’s purpose?

Signup and view all the flashcards

Safety when operating a Lathe?

Safety when operating a Lathe?

Signup and view all the flashcards

Study Notes

- Centre Lathe is a machine that removes metal from a cylindrical metal piece to achieve the desired size or shape.

Parts of the Centre Lathe

- The headstock contains the gears and mechanisms to drive the spindle

- Chuck: holds the workpiece

- Guard: provides safety by protecting the operator from flying chips and coolant

- Coolant supply: cools and lubricates the cutting tool and workpiece

- Light: illuminates the work area

- Tool post: secures the cutting tool

- Top slide: provides fine adjustments to the cutting tool position

- Gear levers: control the spindle speed

- Tailstock: supports the workpiece at the opposite end of the headstock

- Leadscrew: used for threading operations

- Motor lever: starts and stops the motor

- Cross slide: moves the cutting tool perpendicular to the lathe axis

- Saddle handle: controls the longitudinal movement of the saddle

- Feedshaft: provides automated longitudinal feed to the cutting tool

- Emergency stop: immediately stops the lathe

- Lathe bed: is the base of the lathe and provides a rigid support for all the components.

Equipment used

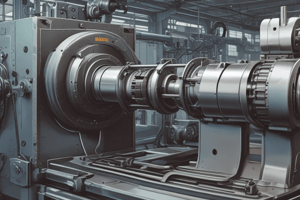

- Three-jaw chucks allow for quick and accurate centering because the jaws move simultaneously.

- Four-jaw chucks allow each jaw to be adjusted independently, making them suitable for holding irregularly shaped workpieces.

- Chuck key: is used to tighten or loosen the chuck jaws.

- Live centre: has a bearing rotation, which provides better rotation, making it suitable for supporting workpieces in between centres

- Dead centre: is a metal shaft with a point.

- Centre drill: creates holes for the live or dead centres.

Metal Lathe Tools

- Lathe cutting tools: made from high-speed steel.

- Shank: is the part of the tool that is fixed into the tool post.

- The cutting tool should be centred to the same height as the tip of the tailstock centre to ensure good finish.

Operations on the Metal Lathe

- Facing off: A piece of steel is placed in the chuck, and a lathe cutting tool levels the end.

- Parallel turning: A layer of material is removed from the rod's surface, with a Vernier calliper used to measure.

- Taper turning: A small amount of metal is removed to form the taper.

- Drilling: The tailstock supports the drilling with a drill chuck attachment.

- Knurling: A knurling tool presses a pattern onto a round section, typically for a grip.

Health and Safety

- Always receive safety instruction before operating the centre lathe.

- The guard must be in position during operation.

- The material must be securely placed in the chuck.

- The metal should not extend too far from the chuck as this increases the risk of an accident.

- Always wear safety goggles

- Hands and fingers must be kept at a safe distance from rotating parts.

- Lathes should have emergency stop switches.

- The machine should be set to operate at recommended speeds and feeds.

- Apply appropriate coolants to the material being turned.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.