What are the stages involved in extracting alumina from bauxite?

Understand the Problem

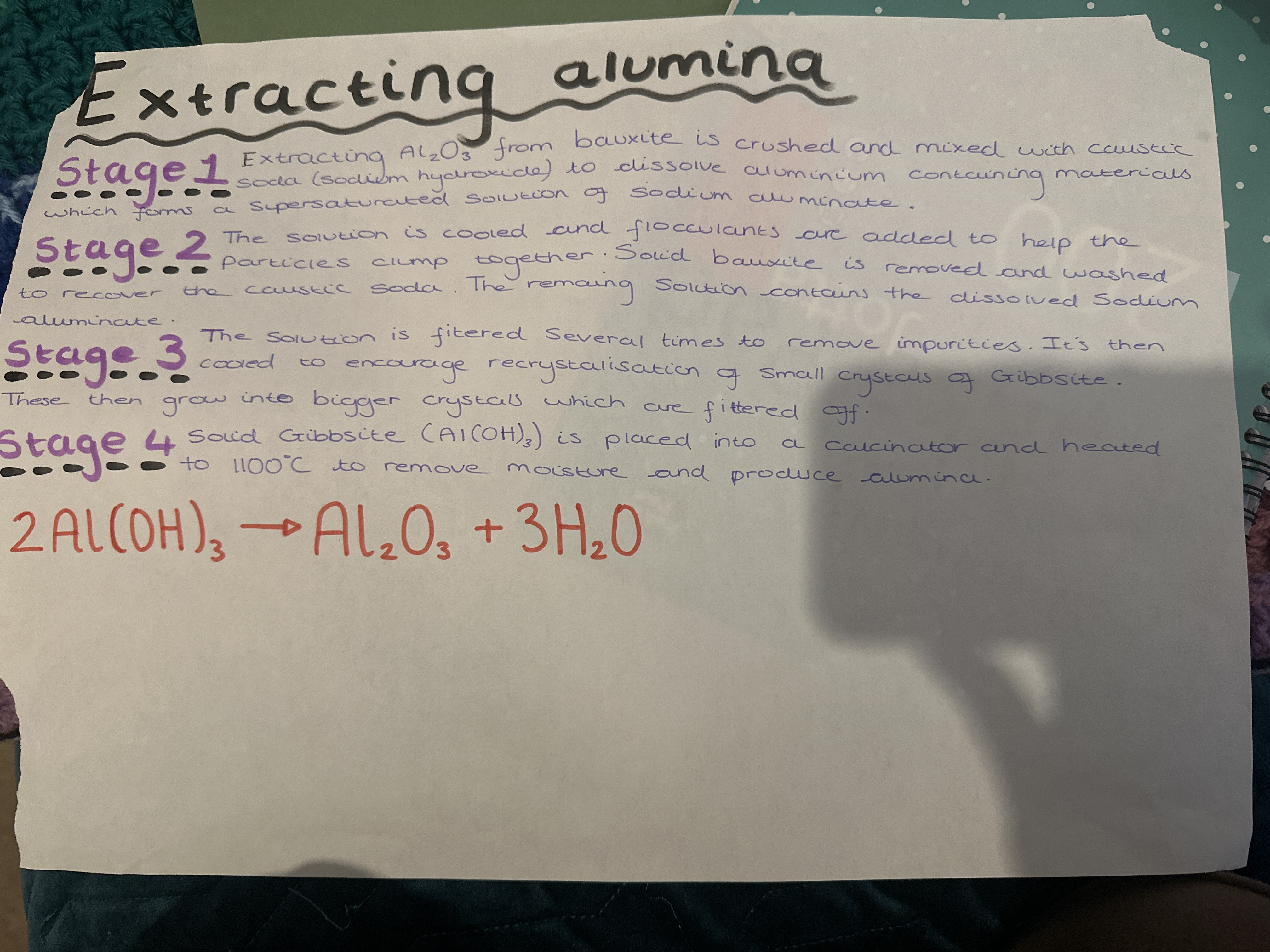

The question outlines the process of extracting alumina from bauxite, detailing the stages and chemical reactions involved. It describes the practical steps taken to purify and convert bauxite into alumina, including the necessary materials and reactions.

Answer

Crush bauxite, dissolve in caustic soda, filter impurities, crystallize gibbsite, heat to get alumina.

The process involves crushing bauxite, dissolving it in caustic soda, filtering impurities, crystallizing gibbsite, and heating to obtain alumina.

Answer for screen readers

The process involves crushing bauxite, dissolving it in caustic soda, filtering impurities, crystallizing gibbsite, and heating to obtain alumina.

More Information

This process is known as the Bayer Process, widely used for refining bauxite into alumina, which is the precursor to aluminum.

Tips

A common mistake is not ensuring complete impurity removal, which can affect the purity of the final alumina.

Sources

- Bayer process - Wikipedia - en.wikipedia.org

- Extracting aluminium from bauxite - aluminum - Chemguide - chemguide.co.uk

- How is alumina obtained from bauxite? - BYJU'S - byjus.com

AI-generated content may contain errors. Please verify critical information