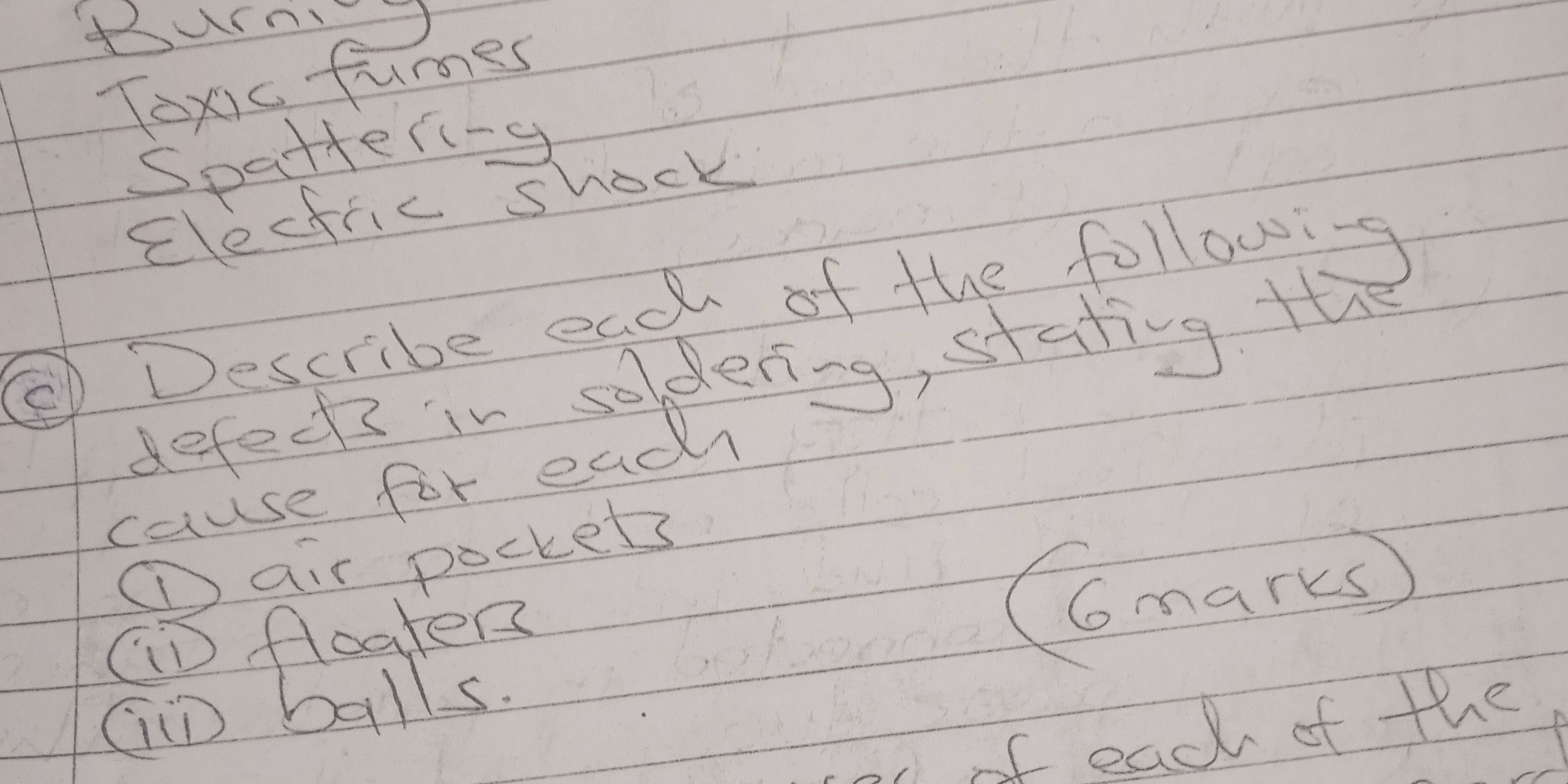

Describe each of the following defects in soldering, stating the cause for each: air pockets, floaters, balls.

Understand the Problem

The question asks to describe the defects in soldering, especially related to air pockets, floaters, and balls, including the cause for each. This involves understanding common soldering issues and their origins.

Answer

Air pockets are gaps in the solder joint caused by contamination; floaters refer to components not properly seated; solder balls are small solder spheres caused by flux gassing, design issues or solder paste problems.

Here are the descriptions of the defects in soldering:

- Air Pockets (Voids): These are gaps or holes within the solder joint, caused by contamination or poor wetting.

- Floaters: This term isn't standard in soldering defect terminology. It may refer to a component that isn't properly seated on the PCB, or lifted off the board due to uneven solder melting, surface tension or other factors.

- Solder Balls: Small spheres of solder scattered around the board. They are caused by the gassing and spitting of flux, improper pad design, weak solder paste, or reflow profile issues.

Answer for screen readers

Here are the descriptions of the defects in soldering:

- Air Pockets (Voids): These are gaps or holes within the solder joint, caused by contamination or poor wetting.

- Floaters: This term isn't standard in soldering defect terminology. It may refer to a component that isn't properly seated on the PCB, or lifted off the board due to uneven solder melting, surface tension or other factors.

- Solder Balls: Small spheres of solder scattered around the board. They are caused by the gassing and spitting of flux, improper pad design, weak solder paste, or reflow profile issues.

More Information

Identifying and understanding the causes of soldering defects are crucial for ensuring the reliability and functionality of electronic devices.

Tips

It's important to use proper soldering techniques, materials, and equipment to minimize the risk of defects. Regular inspection and testing can also catch defects early.

Sources

- Solder Balls or Solder Balling on a PCB - Wave Soldering Defects - epectec.com

- Soldering Defects: Identification, Causes, and Prevention - ELEPCB - elepcb.com

- [PDF] SMT TROUBLE SHOOTING GUIDE - AIM Solder - aimsolder.com

AI-generated content may contain errors. Please verify critical information