Podcast

Questions and Answers

What is the main advantage of the method of selection mentioned in the content?

What is the main advantage of the method of selection mentioned in the content?

- It involves complex machinery.

- It is more accurate than pegged lattice. (correct)

- It is slower than pegged lattice.

- It requires more manual effort to prepare.

What is the primary function of the locking bars in the Hattersley dobby mechanism?

What is the primary function of the locking bars in the Hattersley dobby mechanism?

- To prevent the knives from moving upward.

- To increase the loom speed.

- To hold the baulk during weave selection. (correct)

- To control the reciprocating motion of the knives.

What distinguishes Hattersley dobbies from Keighly dobbies?

What distinguishes Hattersley dobbies from Keighly dobbies?

- Keighly dobbies are faster than Hattersley.

- Hattersley dobbies are double lift positive type. (correct)

- Hattersley dobbies are single lift, while Keighly are double lift.

- Hattersley dobbies do not utilize reciprocating knives.

What is the maximum speed achievable by the reciprocating dobbies mentioned?

What is the maximum speed achievable by the reciprocating dobbies mentioned?

What upgrade does the rotary dobby represent compared to reciprocating dobbies?

What upgrade does the rotary dobby represent compared to reciprocating dobbies?

What role do the push bars play in the Hattersley dobby mechanism?

What role do the push bars play in the Hattersley dobby mechanism?

Which components are necessary for the upward and downward motions in the Hattersley dobby mechanism?

Which components are necessary for the upward and downward motions in the Hattersley dobby mechanism?

Which component is NOT a part of the Hattersley dobby mechanism?

Which component is NOT a part of the Hattersley dobby mechanism?

What is the total number of ends given the ends per inch and the width of the fabric?

What is the total number of ends given the ends per inch and the width of the fabric?

How many repeats can the jacquard handle if the jacquard capacity is 600 and ends per repeat is 200?

How many repeats can the jacquard handle if the jacquard capacity is 600 and ends per repeat is 200?

What is the utilized jacquard capacity when 3 repeats are handled with 200 ends per repeat?

What is the utilized jacquard capacity when 3 repeats are handled with 200 ends per repeat?

What is the formula to calculate harnesses per hook?

What is the formula to calculate harnesses per hook?

If a jacquard has a capacity of 400 and is handling ends per repeat of 150, how many repeats can it effectively handle?

If a jacquard has a capacity of 400 and is handling ends per repeat of 150, how many repeats can it effectively handle?

What is the width of the repeat calculated from ends per repeat and ends per inch?

What is the width of the repeat calculated from ends per repeat and ends per inch?

What is the height of the repeat calculated from picks per repeat and picks per inch?

What is the height of the repeat calculated from picks per repeat and picks per inch?

What can be said about the maximum ends per inch achievable on the loom?

What can be said about the maximum ends per inch achievable on the loom?

What are the two types of jacquards based on the selection method?

What are the two types of jacquards based on the selection method?

Which component is primarily associated with mechanical jacquards?

Which component is primarily associated with mechanical jacquards?

How are electronic jacquards different from mechanical jacquards in terms of operation?

How are electronic jacquards different from mechanical jacquards in terms of operation?

What advantage does the endless plastic paper have over punched cards in jacquard mechanisms?

What advantage does the endless plastic paper have over punched cards in jacquard mechanisms?

In single cylinder jacquards, how many operating cylinders are available?

In single cylinder jacquards, how many operating cylinders are available?

What mechanism is primarily responsible for lifting the hooks in electronic jacquards?

What mechanism is primarily responsible for lifting the hooks in electronic jacquards?

What is a characteristic of double cylinder jacquards?

What is a characteristic of double cylinder jacquards?

Which statement correctly defines the term 'single lift negative shedding mechanism'?

Which statement correctly defines the term 'single lift negative shedding mechanism'?

What is the casting out plan based on the given harness density and ends per inch required?

What is the casting out plan based on the given harness density and ends per inch required?

What is the effective jacquard capacity when utilizing the casting out plan?

What is the effective jacquard capacity when utilizing the casting out plan?

Which jacquard shedding mechanism works after every two picks and is used for higher speed looms?

Which jacquard shedding mechanism works after every two picks and is used for higher speed looms?

What characteristic defines coarse pitch jacquards compared to fine pitch jacquards?

What characteristic defines coarse pitch jacquards compared to fine pitch jacquards?

Which of the following is a typical size of coarse pitch jacquard?

Which of the following is a typical size of coarse pitch jacquard?

What term refers to the distance between the centers of two consecutive needles in jacquard systems?

What term refers to the distance between the centers of two consecutive needles in jacquard systems?

What is the remaining jacquard capacity when considering the utilized hooks?

What is the remaining jacquard capacity when considering the utilized hooks?

What is a primary classification basis for jacquard shedding systems?

What is a primary classification basis for jacquard shedding systems?

What happens to the hook during the next pick cycle if it has been lifted and is required to remain lifted?

What happens to the hook during the next pick cycle if it has been lifted and is required to remain lifted?

What is the primary function of the solenoids in the electronic jacquard shedding mechanism?

What is the primary function of the solenoids in the electronic jacquard shedding mechanism?

What advantage does electronic jacquard shedding have over traditional methods?

What advantage does electronic jacquard shedding have over traditional methods?

What causes the harness to lower into the bottom shed position in the shedding mechanism?

What causes the harness to lower into the bottom shed position in the shedding mechanism?

What was the first year that an electronic jacquard was introduced?

What was the first year that an electronic jacquard was introduced?

What is the function of the supplementary hook in the shedding mechanism?

What is the function of the supplementary hook in the shedding mechanism?

How does the electronic jacquard shedding system update its weaving patterns?

How does the electronic jacquard shedding system update its weaving patterns?

What happens if the feeling needle does not have a hole for the next pick cycle?

What happens if the feeling needle does not have a hole for the next pick cycle?

What will happen to the heald frame when there are no pegs for both feelers (F1 & F2)?

What will happen to the heald frame when there are no pegs for both feelers (F1 & F2)?

What is the state of the heald frame during the first pick when there is a peg for Feeler (F1) and no peg for Feeler (F2)?

What is the state of the heald frame during the first pick when there is a peg for Feeler (F1) and no peg for Feeler (F2)?

During the second pick, what occurs when there is no peg for Feeler (F1) and a peg for Feeler (F2)?

During the second pick, what occurs when there is no peg for Feeler (F1) and a peg for Feeler (F2)?

When both feelers (F1 & F2) have pegs, what is the outcome for the heald frame on two consecutive picks?

When both feelers (F1 & F2) have pegs, what is the outcome for the heald frame on two consecutive picks?

In the scenario where there is a peg for Feeler (F1) and no peg for Feeler (F2), what is the state of the heald frame during the second pick?

In the scenario where there is a peg for Feeler (F1) and no peg for Feeler (F2), what is the state of the heald frame during the second pick?

Which knives catch hooks in the case of both feelers having pegs during the first pick?

Which knives catch hooks in the case of both feelers having pegs during the first pick?

What happens to the heald frame during the first pick when there is no peg for Feeler (F2)?

What happens to the heald frame during the first pick when there is no peg for Feeler (F2)?

What results in both knives missing their respective hooks during a pick?

What results in both knives missing their respective hooks during a pick?

Flashcards

No peg for both feelers (F1 & F2)

No peg for both feelers (F1 & F2)

When neither feeler (F1 nor F2) has a peg, the heald frame stays down on consecutive picks.

Peg for F1, no peg for F2

Peg for F1, no peg for F2

A peg for feeler F1 lifts the heald frame on the first pick but the heald frame stays down on the second because F2 has no peg.

No peg for F1, peg for F2

No peg for F1, peg for F2

When F1 has no peg, the frame is down on the first pick, and then F2 lifts it up on the second pick

Peg for both feelers (F1 & F2)

Peg for both feelers (F1 & F2)

Signup and view all the flashcards

Heald Frame

Heald Frame

Signup and view all the flashcards

Feelers (F1 & F2)

Feelers (F1 & F2)

Signup and view all the flashcards

Knives (K1 & K2)

Knives (K1 & K2)

Signup and view all the flashcards

Hooks (H1 & H2)

Hooks (H1 & H2)

Signup and view all the flashcards

Hattersley Double Lift Positive (HDLP) Dobby

Hattersley Double Lift Positive (HDLP) Dobby

Signup and view all the flashcards

Reciprocating Knives

Reciprocating Knives

Signup and view all the flashcards

Double Lift Positive

Double Lift Positive

Signup and view all the flashcards

Rotary Dobby

Rotary Dobby

Signup and view all the flashcards

Weave Selection

Weave Selection

Signup and view all the flashcards

Dobby

Dobby

Signup and view all the flashcards

Loom Speed

Loom Speed

Signup and view all the flashcards

Punching Machine

Punching Machine

Signup and view all the flashcards

Jacquard Capacity

Jacquard Capacity

Signup and view all the flashcards

Ends per Repeat

Ends per Repeat

Signup and view all the flashcards

Number of Repeats Handled

Number of Repeats Handled

Signup and view all the flashcards

Utilized Jacquard Capacity

Utilized Jacquard Capacity

Signup and view all the flashcards

Harnesses per Hook

Harnesses per Hook

Signup and view all the flashcards

Width of Repeat

Width of Repeat

Signup and view all the flashcards

Height of Repeat

Height of Repeat

Signup and view all the flashcards

Casting Out

Casting Out

Signup and view all the flashcards

Casting Out Plan

Casting Out Plan

Signup and view all the flashcards

Effective Jacquard Capacity

Effective Jacquard Capacity

Signup and view all the flashcards

Remaining Jacquard Capacity

Remaining Jacquard Capacity

Signup and view all the flashcards

Single Lift Jacquard

Single Lift Jacquard

Signup and view all the flashcards

Double Lift Jacquard

Double Lift Jacquard

Signup and view all the flashcards

Coarse Pitch Jacquard

Coarse Pitch Jacquard

Signup and view all the flashcards

Fine Pitch Jacquard

Fine Pitch Jacquard

Signup and view all the flashcards

French Pitch Jacquard

French Pitch Jacquard

Signup and view all the flashcards

Jacquard Types

Jacquard Types

Signup and view all the flashcards

Mechanical Jacquard

Mechanical Jacquard

Signup and view all the flashcards

Electronic Jacquard

Electronic Jacquard

Signup and view all the flashcards

Single Cylinder Jacquard

Single Cylinder Jacquard

Signup and view all the flashcards

Double Cylinder Jacquard

Double Cylinder Jacquard

Signup and view all the flashcards

Jacquard Shedding Mechanism

Jacquard Shedding Mechanism

Signup and view all the flashcards

Single Lift Single Cylinder (SLSC)

Single Lift Single Cylinder (SLSC)

Signup and view all the flashcards

Negative Shedding

Negative Shedding

Signup and view all the flashcards

Single Cylinder Selection

Single Cylinder Selection

Signup and view all the flashcards

Supplementary Hook (H)

Supplementary Hook (H)

Signup and view all the flashcards

Feeling Needle

Feeling Needle

Signup and view all the flashcards

Swing Board

Swing Board

Signup and view all the flashcards

Solenoid

Solenoid

Signup and view all the flashcards

CAD Software

CAD Software

Signup and view all the flashcards

EJS Advantages

EJS Advantages

Signup and view all the flashcards

Study Notes

Weaving Mechanisms

- Warping yarns are divided into two layers: a top shed line and a bottom shed line.

- The gap between these layers is called a shed.

- Shedding mechanisms are used to raise and lower heald frames carrying warp yarns.

- These mechanisms create different types of sheds: bottom closed, semi-open, center closed, and fully open.

- Crank shedding, tappet shedding, dobby shedding, and jacquard shedding are four types of shedding mechanisms.

- Jacquard shedding uses individual harnesses to lift individual warp yarns.

- Positive shedding involves raising and lowering heald frames using double cams.

- Negative shedding uses another mechanism to return heald frames to their original position, such as springs.

- Reversing media, like springs and pulleys, returns the frames to their starting position.

- Crank shedding is the simplest and fastest shedding mechanism, suitable for plain weaves.

- Tappet shedding is simple, inexpensive, and suitable for plain and some basic twill weaves.

- Dobby shedding is more complex, costly, but suitable for a wider range of weave designs.

- Jacquard shedding is the most complex mechanism, used for intricate and specialized designs, capable of higher speeds.

Objectives of Shedding Motion

- Raising and lowering heald frames that carry warp yarns.

- Creating an opening for picking media to pass through.

- Changing the warp yarn position to interlace warp and weft as needed for weaving design.

Types of Shedding Mechanisms

- Crank shedding

- Tappet shedding

- Dobby shedding

- Jacquard shedding

Types of Sheds

- Bottom closed shed

- Semi open shed

- Center closed shed

- Fully open shed

Cam

- A specially designed rotating or sliding metal piece.

- Used to convert rotary motion to linear reciprocating motion (or vice versa).

- Works with a follower to transmit motion.

- Shapes are different depending on the weave design.

- A cam always has a flatter portion, or base (dwell) and a pointed portion, or nose.

- Tappet cams are designed for specific weave designs, e.g., one cam for 3/1 twill weave.

Dwell Period

- The time the reed is stationary at its lowest point in a given cycle.

- Directly relates to machine width and indirectly to machine speed.

Throw or Lift of a Cam

- The difference between the farthest and nearest points of contact on a cam in a cycle.

- Measures maximum displacement for a cam to lift a heald frame.

Repeat Size Limitations of Cams

- Practical limitations on the number of cams for a given weave.

- Generally, the weave designs for dobby and jacquard mechanisms can handle 8 to 12 picks per repeat.

- Increased number of cams means an increase in slope that needs to be managed.

Shed Settings

- Adjusting the shed opening is achieved by moving a fork lever up or down with a clamp screw.

- Increasing the length of link rods increases shed height; vice versa.

Dobby Shedding

- A versatile method suitable for 12 to 32 heald frames.

- Used for creating a shed for more complicated and intricate weaves like stripes, checks and borders.

Principle of Dobby Shedding

- Dobby shedding mechanisms have a drive mechanism, a selection mechanism, and a lifting mechanism.

Classification of Dobby Shedding

- Based on the working principle (lever/reciprocating or rotary).

- Based on the driving method used.

- Based on the weave design selection method (continuous pattern card or electronic).

Electronic Rotary Dobby

- The movement of the ratchet is achieved electronically using solenoids/electromagnets.

- The lifting order of the weave design by a computer system to the solenoids.

- Faster, more sophisticated and has more control mechanisms compared to other types of shedding systems.

Jacquard Shedding

- Invented by a French silk weaver Joseph Marie Jacquard in 1801

- Uses individual harnesses, instead of heald frames, to create a shed.

- Each end (warp yarn) passes through its own individual harness eye, controlled by the jacquard shedding mechanism.

- More complex, but allows for more complex design patterns.

- Modern jacquard shedding systems are highly sophisticated, capable of handling 25,000 picks per repeat.

Jacquard Harness System

- Suspended above the loom.

- Connected to the loom through a jacquard harness system (cords, heald eyes and lingoes).

- A comber board sits below the jacquard mechanism, to line up the parallel harnesses.

- Capacity depends on the number of hooks in one row and number of rows.

Jacquard Card Punching

- To each hook, multiple harnesses are attached (number depends on the weave design's end per repeat).

- Jacquard cards contain the information to control the harness movement for a given weave.

- Cards are laced together to form loops in the system which are repeated throughout the weave cycle.

Casting Out

- A technique used to adjust the harness density of a jacquard to a desired end density per inch.

- Calculating how to adjust the hook usage to achieve the desired width or weave effects when the harness density is not equal to the desired end density.

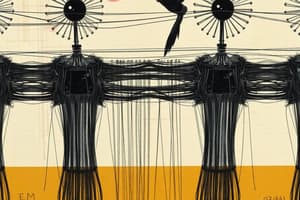

Hattersley Double Lift Positive (HDLP) Dobby

-

Very similar to Keighley dobby.

-

Reciprocating knives are used in this automated system, but the baulk should be rigidly attached to the heald frame for both up and down motions.

-

Has two sets of knives to achieve double lift.

-

Other descriptions of mechanism(s) details for different weaving types (e.g. Fine Pitch Jacquard (Vincenzi etc.)) are included in this document.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.