Podcast

Questions and Answers

What type of burner is typically used in the vertical two drum water tube boiler?

What type of burner is typically used in the vertical two drum water tube boiler?

- Steam atomising burner (correct)

- Solid fuel burner

- Electric burner

- Gas-fired burner

What feature helps ensure a sufficient dryness of steam in the steam drum?

What feature helps ensure a sufficient dryness of steam in the steam drum?

- Vertical solid stays

- Flat plates

- Internal fittings (correct)

- Cylindrical shape

Where are the burner and relevant boiler mountings located in the vertical two drum water tube boiler?

Where are the burner and relevant boiler mountings located in the vertical two drum water tube boiler?

- On top of the boiler (correct)

- Inside the steam drum

- At the bottom of the boiler

- On the side of the boiler

What is the purpose of the manholes in the drums of the boiler?

What is the purpose of the manholes in the drums of the boiler?

What type of construction is used for the steam drum in terms of its plates?

What type of construction is used for the steam drum in terms of its plates?

Which of the following is NOT a characteristic of the burner cone in the boiler?

Which of the following is NOT a characteristic of the burner cone in the boiler?

What design feature aids in accessing the heating coil in the water drum?

What design feature aids in accessing the heating coil in the water drum?

Flashcards are hidden until you start studying

Study Notes

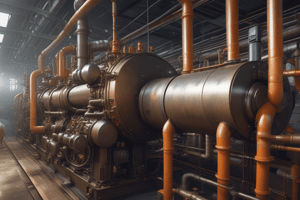

Vertical Two Drum Water Tube Boiler

- Commonly used on ships, featuring a top-fired design.

- Equipped with a steam atomising burner to enhance combustion efficiency.

Control and Monitoring Features

- Local control panel affixed on top for easy operation and monitoring.

- Burner platform provides convenient access for operators.

Structural Design

- Steam drum is cylindrical, equipped with two flat plates of equal thickness.

- Internal pressure supported by vertical solid stays connecting the flat plates.

Distribution and Dryness Control

- Internal fittings ensure uniform distribution of feed water and circulation water.

- Designed for sufficient dryness of steam to enhance performance.

Furnace and Burner Configuration

- Burner cone is integrated into the furnace opening; no refractory materials are used at the furnace top.

- Design promotes efficient heat transfer without additional refractory components.

Maintenance and Inspection

- Manholes strategically located in both steam and water drums for accessibility.

- Ample space within the drums to facilitate inspection and maintenance tasks.

Water Drum Design

- Similar design principles as the steam drum, providing optimal heating coil space.

- Ensures easy access for inspections, enhancing overall maintenance efficiency.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.