Podcast

Questions and Answers

What is the purpose of the inclined water tubes in a Babcock and Wilcox boiler?

What is the purpose of the inclined water tubes in a Babcock and Wilcox boiler?

- To direct the flow of hot gases between the tubes

- To ensure proper circulation of water through the boiler (correct)

- To facilitate efficient cleaning and inspection of the tubes

- To increase the angle of inclination to 30°

What is the angle of inclination of the water tubes to the horizontal in a Babcock and Wilcox boiler?

What is the angle of inclination of the water tubes to the horizontal in a Babcock and Wilcox boiler?

- 40°

- 5°

- 25°

- 15° (correct)

Why are water tube boilers preferred for pressures above 10 bar and capacities exceeding 7000 kg of steam per hour?

Why are water tube boilers preferred for pressures above 10 bar and capacities exceeding 7000 kg of steam per hour?

- To improve fuel combustion

- To reduce maintenance costs

- For ease of transportation

- Due to their higher efficiency (correct)

What is the function of the feed valve in a Babcock and Wilcox boiler?

What is the function of the feed valve in a Babcock and Wilcox boiler?

How does the water circulate through a Babcock and Wilcox boiler?

How does the water circulate through a Babcock and Wilcox boiler?

Where does the steam collect in a Babcock and Wilcox boiler?

Where does the steam collect in a Babcock and Wilcox boiler?

What is the purpose of the superheater tubes in a boiler?

What is the purpose of the superheater tubes in a boiler?

How does a Babcock Wilcox water tube boiler with cross drum differ from a longitudinal drum boiler?

How does a Babcock Wilcox water tube boiler with cross drum differ from a longitudinal drum boiler?

What is the main function of the mud drum in a Stirling water tube boiler?

What is the main function of the mud drum in a Stirling water tube boiler?

Why is a baffle provided at the mud drum in a Stirling water tube boiler?

Why is a baffle provided at the mud drum in a Stirling water tube boiler?

What is the purpose of the fire brick arch in a fire tube boiler?

What is the purpose of the fire brick arch in a fire tube boiler?

How are the steam drums and mud drum supported in a Stirling water tube boiler?

How are the steam drums and mud drum supported in a Stirling water tube boiler?

Why is a babcock Wilcox water tube boiler preferred for large central power stations?

Why is a babcock Wilcox water tube boiler preferred for large central power stations?

What is a common characteristic of both Babcock Wilcox and Stirling water tube boilers?

What is a common characteristic of both Babcock Wilcox and Stirling water tube boilers?

What can be inferred about fire tube boilers from the text?

What can be inferred about fire tube boilers from the text?

What happens when the blow off cock is used in a water tube boiler?

What happens when the blow off cock is used in a water tube boiler?

What is the purpose of Sugden's superheater in a Lancashire boiler?

What is the purpose of Sugden's superheater in a Lancashire boiler?

How are the 'U' tubes attached in Sugden's superheater?

How are the 'U' tubes attached in Sugden's superheater?

In Sugden's superheater, how many tubes are generally carried by one pair of headers?

In Sugden's superheater, how many tubes are generally carried by one pair of headers?

How is the path of gases controlled in Sugden's superheater?

How is the path of gases controlled in Sugden's superheater?

What happens when the steam is passed through the superheater of a Lancashire boiler?

What happens when the steam is passed through the superheater of a Lancashire boiler?

What is the main function of a steam separator in a boiler system?

What is the main function of a steam separator in a boiler system?

What is the primary purpose of hand holes provided at the ends of each cross tube in a boiler?

What is the primary purpose of hand holes provided at the ends of each cross tube in a boiler?

In a vertical boiler, what is the function of a manhole?

In a vertical boiler, what is the function of a manhole?

Why is a Cochran boiler considered to be self-contained and easily transportable?

Why is a Cochran boiler considered to be self-contained and easily transportable?

What is the purpose of a blow off cock in a Cornish boiler?

What is the purpose of a blow off cock in a Cornish boiler?

In a Lancashire boiler, why are there multiple rings of cylindrical form constructed inside the shell?

In a Lancashire boiler, why are there multiple rings of cylindrical form constructed inside the shell?

Which boiler mounting is primarily responsible for controlling the water level in a Cochran boiler?

Which boiler mounting is primarily responsible for controlling the water level in a Cochran boiler?

What does the hemispherical shape of the crown in a Cochran boiler primarily help with?

What does the hemispherical shape of the crown in a Cochran boiler primarily help with?

Why are flue tubes used in Cochran boilers?

Why are flue tubes used in Cochran boilers?

What is the main reason for having two large tubes placed inside the cylindrical shell of a Lancashire boiler?

What is the main reason for having two large tubes placed inside the cylindrical shell of a Lancashire boiler?

What is the purpose of having fusible plug as one of the mountings in a Cornish boiler?

What is the purpose of having fusible plug as one of the mountings in a Cornish boiler?

What is the function of the arch of fire bricks in a locomotive boiler?

What is the function of the arch of fire bricks in a locomotive boiler?

In a locomotive boiler, where is the coal introduced for burning?

In a locomotive boiler, where is the coal introduced for burning?

What is the purpose of a steam dome in a locomotive boiler?

What is the purpose of a steam dome in a locomotive boiler?

What is the main function of dampers in a locomotive boiler?

What is the main function of dampers in a locomotive boiler?

Why is natural draught not achievable in a locomotive boiler without artificial arrangements?

Why is natural draught not achievable in a locomotive boiler without artificial arrangements?

What is one of the demerits associated with locomotive boilers?

What is one of the demerits associated with locomotive boilers?

In a locomotive boiler, what happens to the hot gases generated from burning coal?

In a locomotive boiler, what happens to the hot gases generated from burning coal?

What component prevents entry of burning coal and ashes into furnace tubes?

What component prevents entry of burning coal and ashes into furnace tubes?

Why are some dampers fitted at both ends of an ash pit in a locomotive boiler?

Why are some dampers fitted at both ends of an ash pit in a locomotive boiler?

What is a distinctive feature of locomotive boilers compared to other types?

What is a distinctive feature of locomotive boilers compared to other types?

What is the main difference between a single-acting pump and a double-acting pump?

What is the main difference between a single-acting pump and a double-acting pump?

In a duplex direct-acting steam pump, how are the slide valves in each cylinder operated?

In a duplex direct-acting steam pump, how are the slide valves in each cylinder operated?

What is the purpose of an injector in a boiler system?

What is the purpose of an injector in a boiler system?

Why is an injector commonly used for vertical and locomotive boilers?

Why is an injector commonly used for vertical and locomotive boilers?

What type of pumps are rotary feed pumps, and how are they commonly powered?

What type of pumps are rotary feed pumps, and how are they commonly powered?

What role does an economiser play in a boiler system?

What role does an economiser play in a boiler system?

What distinguishes an independent type economiser from an integral type economiser?

What distinguishes an independent type economiser from an integral type economiser?

What is a unique advantage of using an injector for feeding water into a boiler?

What is a unique advantage of using an injector for feeding water into a boiler?

Why can an injector not be employed in large capacity high pressure boilers?

Why can an injector not be employed in large capacity high pressure boilers?

What feature allows an economiser to enhance thermal efficiency in a boiler system?

What feature allows an economiser to enhance thermal efficiency in a boiler system?

What is the most popular type of boiler for steaming capacities up to about 1000 kg/h and a pressure of about 17 bar?

What is the most popular type of boiler for steaming capacities up to about 1000 kg/h and a pressure of about 17 bar?

Why are shell boilers considerably cheaper than water tube boilers for steam applications that require less than about 30000 kg of steam per hour?

Why are shell boilers considerably cheaper than water tube boilers for steam applications that require less than about 30000 kg of steam per hour?

What factor influences the choice between water tube boilers and shell boilers according to the text?

What factor influences the choice between water tube boilers and shell boilers according to the text?

In high pressure boilers, what is the main method used for water circulation?

In high pressure boilers, what is the main method used for water circulation?

How does the arrangement of tubing in high pressure boilers help improve efficiency?

How does the arrangement of tubing in high pressure boilers help improve efficiency?

What feature distinguishes high pressure boilers used for power generation from other types of boilers?

What feature distinguishes high pressure boilers used for power generation from other types of boilers?

What is a limitation of using natural circulation in high pressure boilers?

What is a limitation of using natural circulation in high pressure boilers?

Why are water tube boilers generally preferred over shell boilers for high pressure and high output applications?

Why are water tube boilers generally preferred over shell boilers for high pressure and high output applications?

What distinguishes high pressure boilers employed for power generation from other types in terms of steam temperature?

What distinguishes high pressure boilers employed for power generation from other types in terms of steam temperature?

What is the primary function of an economiser in a boiler system?

What is the primary function of an economiser in a boiler system?

In a boiler system, what is the purpose of an air preheater?

In a boiler system, what is the purpose of an air preheater?

What advantage does superheated steam provide in a steam plant?

What advantage does superheated steam provide in a steam plant?

Why are superheaters located in the path of furnace gases in a boiler system?

Why are superheaters located in the path of furnace gases in a boiler system?

What is the purpose of having a blow-off cock in a boiler system?

What is the purpose of having a blow-off cock in a boiler system?

Which part of a boiler system is responsible for increasing air temperature before it enters the furnace?

Which part of a boiler system is responsible for increasing air temperature before it enters the furnace?

What is one advantage of using an economiser in a boiler system as described in the text?

What is one advantage of using an economiser in a boiler system as described in the text?

In a boiler system, what is the primary function of a superheater?

In a boiler system, what is the primary function of a superheater?

Why are radiantsuperheaters used where high superheat temperature is required?

Why are radiantsuperheaters used where high superheat temperature is required?

What part of a boiler system helps to maintain a clean external pipe surface for better heat transfer?

What part of a boiler system helps to maintain a clean external pipe surface for better heat transfer?

Why is it important to use pumps in high-pressure boilers?

Why is it important to use pumps in high-pressure boilers?

What is the primary purpose of using small diameter tubes in large numbers in high-pressure boilers?

What is the primary purpose of using small diameter tubes in large numbers in high-pressure boilers?

How does pressurised combustion impact the operation of high-pressure boilers?

How does pressurised combustion impact the operation of high-pressure boilers?

What is one advantage of the Lamont boiler over the Loeffler boiler?

What is one advantage of the Lamont boiler over the Loeffler boiler?

Why does a Loeffler boiler prevent the flow of water into boiler tubes?

Why does a Loeffler boiler prevent the flow of water into boiler tubes?

What is a significant advantage of Loeffler boilers over directly heated boilers?

What is a significant advantage of Loeffler boilers over directly heated boilers?

Why are accessories necessary for steam boilers?

Why are accessories necessary for steam boilers?

Why is a reciprocating pump used as a feed pump in boilers?

Why is a reciprocating pump used as a feed pump in boilers?

What distinguishes a double-acting pump from a single-acting pump?

What distinguishes a double-acting pump from a single-acting pump?

What is the function of a rotary pump in a boiler system?

What is the function of a rotary pump in a boiler system?

Flashcards are hidden until you start studying

Study Notes

Water Tube Boilers

- Water tube boilers are used when pressure above 10 bar and capacity in excess of 7000 kg of steam per hour is required.

- They have two types: Horizontal straight tube (Babcock and Wilcox) and Bent tube boiler.

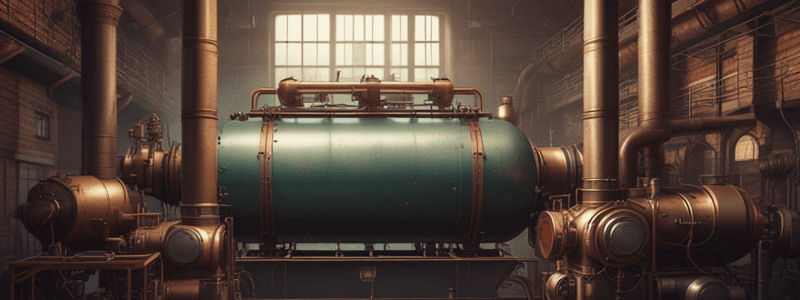

Babcock and Wilcox Boiler

- It is an example of horizontal straight tube boiler.

- It consists of a drum connected to a series of front end and rear end headers by short riser tubes.

- To these headers are connected a series of inclined water tubes of solid drawn mild steel.

- A feed valve is provided to fill the drum and inclined tubes with water.

- The water flows through the inclined tubes via downtake header and goes back into the shell in the form of water and steam via uptake header.

Stirling Boiler

- It is an example of bent tube boiler.

- It consists of two upper drums known as steam drums and a lower drum known as mud or water drum.

- The steam drums are connected to mud drum by bank of bent tubes.

- The steam and water space of the steam drums are interconnected with each other, so that balance of water and steam may be obtained.

- Manhole at one end of each drum is provided for carrying out cleaning operation.

Fire Tube Boilers

- The various fire tube boilers are described as follows:

- Simple vertical boiler

- Cochran boiler

- Cornish boiler

- Lancashire boiler

Simple Vertical Boiler

- It consists of a cylindrical shell, the greater portion of which is full of water and remaining is the steam space.

- At the bottom of the fire box is grate on which fuel is burnt and the ash from it falls in the ash pit.

- The fire box is provided with two cross tubes.

- It is self-contained and can be transported easily.

Cochran Boiler

- It is one of the best types of vertical multi-tubular boiler.

- It consists of a cylindrical shell with a dome shaped top where the space is provided for steam.

- The rate of production in not exceed 2500 kg/h and pressure 7.5 to 10 bar.

Cornish Boiler

- It consists of a cylindrical shell with flat ends through which passes a smaller flue tube containing the furnace.

- The products of combustion pass from the fire grate forward over the brickwork bridge to the end of the furnace tube.

- It is still used in some industries.

Lancashire Boiler

- It is reliable, has simplicity of design, ease of operation and less operating and maintenance costs.

- It is commonly used in sugar-mills and textile industries where along with the power steam and steam for the process work is also needed.

Boiler Accessories

- Economiser: increases the temperature of the feed water, increases the evaporative capacity of the boiler, and increases the overall efficiency of the plant.

- Air Preheater: increases the temperature of air before it enters the furnace, accelerates the combustion and facilitates the burning of coal.

- Superheater: increases the temperature of the steam above its saturation point, reduces the steam consumption of the engine or turbine, and increases the efficiency of the steam plant.

- Steam Separator: separates the steam from the water and removes any impurities from the steam.### High Pressure Boilers

- In high pressure boilers, pumps are used to maintain forced circulation of water through the tubes of the boiler, ensuring positive circulation and increasing evaporative capacity.

- The use of small diameter tubes in large numbers and multiple circuits increases the efficiency of heat utilisation.

- Pressurised combustion is used to increase the rate of firing of fuel and heat release.

- Compactness of high pressure boilers reduces the required floor space.

- The high velocity of water through the tubes eliminates the tendency of scale formation.

- Uniform heating of all parts reduces the danger of overheating and thermal stress.

Lamont Boiler

- The Lamont boiler works on forced circulation, maintained by a centrifugal pump driven by a steam turbine using steam from the boiler.

- An electrically driven pump is also fitted for emergency situations.

- The boiler can generate 45 to 50 tonnes of superheated steam at a pressure of 130 bar and a temperature of 500°C.

Loeffler Boiler

- The Loeffler boiler solves the problem of salt and sediment deposition on the inner surfaces of the water tubes by preventing the flow of water into the boiler tubes.

- The boiler uses forced circulation and evaporates feed water by means of superheated steam from the superheater.

- The boiler can carry higher salt concentrations and is more compact than indirectly heated boilers with natural circulation.

- Loeffler boilers with a capacity of 100 tonnes/h and operating at 140 bar have been commissioned.

Boiler Mounting and Accessories

- Accessories are auxiliary plants required for steam boilers to operate efficiently.

- Feed pumps are used to deliver feed water to the boiler, with two types: reciprocating and rotary pumps.

Feed Pumps

- Reciprocating pumps consist of a pump cylinder and a piston, with two types: single-acting and double-acting.

- The reciprocating pump may not be suitable for high overloads due to overheating.

- Rotary pumps are of centrifugal type and are commonly run by a small steam turbine or an electric motor.

Scotch Boiler

- The Scotch type marine boiler is a popular boiler for steaming capacities up to 1000 kg/h and pressure of about 17 bar.

- It consists of a cylindrical shell with one to four cylindrical, corrugated steel furnaces.

- The furnaces are internally fired and surrounded by water, with a combustion chamber located at the back end.

High Pressure Boilers

- High pressure boilers are preferred for high pressure and high output applications.

- Unique features of high pressure boilers include:

- Forced circulation of water using pumps.

- Type of tubing, including partial systems and multiple sets.

- Improved methods of heating, such as evaporation above critical pressure, mixing of superheated steam, and increasing water velocity.

- Advantages of high pressure boilers include:

- Increased evaporative capacity.

- Compactness.

- Reduced danger of overheating.

- Improved heat transfer.

Injector

- An injector is a device used to feed water into the boiler, commonly employed for vertical and locomotive boilers.

- It uses steam pressure to increase the pressure and velocity of the feed water.

- Advantages of an injector include:

- Low initial cost.

- Simplicity.

- Compactness.

- Absence of dynamic parts.

- High thermal efficiency.

- Disadvantages of an injector include:

- Low pumping efficiency.

- Inability to force very hot water.

- Irregularity of operation under extreme variation in steam pressure.

Economiser

- An economiser is a device that utilises the waste heat of the flue gases to heat the feed water.

- There are two types of economisers: independent and integral.

- The independent type is installed in a chamber apart from the boiler setting, while the integral type is part of the boiler heating surface.

- Advantages of an economiser include:

- Increased efficiency.

- Reduced fuel consumption.

- Compactness.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.