Podcast

Questions and Answers

Drying of solids is needed for easy-to-handle free-flowing liquids.

Drying of solids is needed for easy-to-handle free-flowing liquids.

False (B)

Product size in drying can range from microns to tens of meters.

Product size in drying can range from microns to tens of meters.

False (B)

Drying times can range from 0.25 sec to five months.

Drying times can range from 0.25 sec to five months.

True (A)

Heat can only be transferred by convection or conduction in drying.

Heat can only be transferred by convection or conduction in drying.

Drying is often the first operation in a manufacturing process.

Drying is often the first operation in a manufacturing process.

Drying refers to the removal of air or gas from a material.

Drying refers to the removal of air or gas from a material.

One of the reasons for drying is to increase the cost of transport.

One of the reasons for drying is to increase the cost of transport.

Drying is carried out for one or more of the following reasons: preservation and storage, reduction in cost of transportation, achieving desired quality of product, etc.

Drying is carried out for one or more of the following reasons: preservation and storage, reduction in cost of transportation, achieving desired quality of product, etc.

Drying is a simple operation involving permanent transfer of heat and mass.

Drying is a simple operation involving permanent transfer of heat and mass.

The chapter is about Drying of Liquids.

The chapter is about Drying of Liquids.

Physical changes that may occur during drying include shrinkage and melting.

Physical changes that may occur during drying include shrinkage and melting.

The chapter is part of the Unit Operations course.

The chapter is part of the Unit Operations course.

The chapter is written by Dr. May Ali alsaffar.

The chapter is written by Dr. May Ali alsaffar.

Drying can occur by effecting vaporization of the liquid by supplying cold to the wet feedstock.

Drying can occur by effecting vaporization of the liquid by supplying cold to the wet feedstock.

Most industrial dryers are of the conduction type with hot air or direct combustion gases as the drying medium.

Most industrial dryers are of the conduction type with hot air or direct combustion gases as the drying medium.

Humidity Measurement is discussed in section 1.5.

Humidity Measurement is discussed in section 1.5.

The chapter covers Humidity Data for Air – Gas system.

The chapter covers Humidity Data for Air – Gas system.

Desirable chemical or biochemical reactions may occur during drying, leading to changes in product quality.

Desirable chemical or biochemical reactions may occur during drying, leading to changes in product quality.

Drying can be used to remove impurities from a material.

Drying can be used to remove impurities from a material.

Rate of Drying is discussed in section 1.6.

Rate of Drying is discussed in section 1.6.

Drying involves only heat transfer.

Drying involves only heat transfer.

The chapter discusses Calculation Method of Drying Rate and Time in section 1.9.

The chapter discusses Calculation Method of Drying Rate and Time in section 1.9.

The chapter is for Third Class Chemical Engineering Department.

The chapter is for Third Class Chemical Engineering Department.

Drying conditions can affect the internal surface area of the final product.

Drying conditions can affect the internal surface area of the final product.

Moisture content of a material is usually expressed in terms of its water vapor content as a percentage of the mass of the wet material.

Moisture content of a material is usually expressed in terms of its water vapor content as a percentage of the mass of the wet material.

Vapor diffusion occurs when the liquid does not vaporize within the material.

Vapor diffusion occurs when the liquid does not vaporize within the material.

Surface diffusion is a proven mechanism of mass transfer.

Surface diffusion is a proven mechanism of mass transfer.

A material will always lose water if it is exposed to air with any humidity.

A material will always lose water if it is exposed to air with any humidity.

Liquid diffusion occurs at any temperature regardless of the boiling point of the liquid.

Liquid diffusion occurs at any temperature regardless of the boiling point of the liquid.

Knudsen diffusion occurs at high temperatures and pressures.

Knudsen diffusion occurs at high temperatures and pressures.

Moisture content is always expressed on a dry basis.

Moisture content is always expressed on a dry basis.

Mass transfer mechanisms in drying of solids always occur independently.

Mass transfer mechanisms in drying of solids always occur independently.

Moisture movement in a wet solid is a complex process.

Moisture movement in a wet solid is a complex process.

Continuous dryers are always operated in a batch mode.

Continuous dryers are always operated in a batch mode.

Material balance is an important consideration for batch dryers only.

Material balance is an important consideration for batch dryers only.

The rate of drying in a continuous direct heat drier is always constant.

The rate of drying in a continuous direct heat drier is always constant.

Drying of solids is only used in the chemical engineering industry.

Drying of solids is only used in the chemical engineering industry.

Drying is only used to remove water from a material.

Drying is only used to remove water from a material.

Heat transfer by radiation is not possible in drying.

Heat transfer by radiation is not possible in drying.

Drying is always the final step in a manufacturing process.

Drying is always the final step in a manufacturing process.

Flashcards are hidden until you start studying

Study Notes

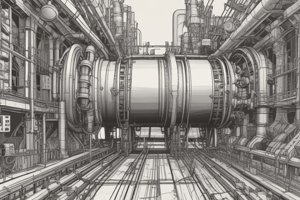

Introduction to Drying of Solids

- Drying of various feedstocks is necessary for easy handling, preservation, and storage, reducing transportation costs, and achieving desired product quality.

- Drying is a complex operation involving transient transfer of heat and mass, along with physical or chemical transformations that may affect product quality and heat and mass transfer mechanisms.

Unique Features of Drying

- Product size can range from microns to tens of centimeters in thickness or depth.

- Product porosity can range from zero to 99.9 percent.

- Drying times can range from 0.25 seconds (tissue paper) to five months (certain hardwood species).

- Production capacities can range from 0.10 kg/h to 100 t/h.

- Product speeds can range from zero (stationary) to 2000 m/s (tissue paper).

- Drying temperatures can range from below the triple point to above the critical point of the liquid.

- Operating pressure can range from a fraction of a millibar to 25 atmospheres.

- Heat can be transferred continuously or intermittently by convection, conduction, radiation, or electromagnetic fields.

Reasons for Drying

- To reduce transportation costs.

- To make materials more suitable for handling (e.g., soap powders, dyestuffs, and fertilizers).

- To provide definite properties (e.g., maintaining the free-flowing nature of salt).

- To remove moisture that may lead to corrosion (e.g., drying of gaseous fuels or benzene prior to chlorination).

Basic Principles of Drying

- Drying involves transient transfer of heat and mass along with physical or chemical transformations that may affect product quality and heat and mass transfer mechanisms.

- Physical changes that may occur include shrinkage, puffing, crystallization, and glass transitions.

- Chemical or biochemical reactions may occur, leading to changes in color, texture, odor, or other properties of the solid product.

Heat and Mass Transfer Mechanisms

- Heat can be supplied by convection (direct dryers), conduction (contact or indirect dryers), radiation, or volumetrically by placing the wet material in a microwave or radio frequency electromagnetic field.

- Over 85 percent of industrial dryers are of the convective type with hot air or direct combustion gases as the drying medium.

- Transport of moisture within the solid may occur by liquid diffusion, vapor diffusion, Knudsen diffusion, surface diffusion, hydrostatic pressure differences, or combinations of these mechanisms.

Moisture Content and Equilibrium

- Moisture content is usually expressed as a percentage of the mass of the dry material.

- If a material is exposed to air at a given temperature and humidity, it will either lose water (if the air has lower humidity) or gain water (if the air has higher humidity) until an equilibrium condition is established.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.