Podcast

Questions and Answers

What is the primary task of the turbine in a gas turbine engine?

What is the primary task of the turbine in a gas turbine engine?

- To compress air

- To generate electricity

- To provide power to drive the compressor and accessories (correct)

- To cool the engine

What is the maximum speed that turbine blade tips may rotate at?

What is the maximum speed that turbine blade tips may rotate at?

- 1500 ft/s (correct)

- 500 ft/s

- 1000 ft/s

- 2000 ft/s

What is the typical entry temperature range of the gas to which the turbine is exposed?

What is the typical entry temperature range of the gas to which the turbine is exposed?

- 1000-2000 °C

- 500-1000 °C

- 1500-2500 °C

- 850-1700 °C (correct)

What is the purpose of exducer vanes in a radial inflow turbine?

What is the purpose of exducer vanes in a radial inflow turbine?

What type of engines are radial inflow turbines sometimes used in?

What type of engines are radial inflow turbines sometimes used in?

What is the shape of the blades in a turbine?

What is the shape of the blades in a turbine?

What is the main function of the nozzle guide vanes in the turbine?

What is the main function of the nozzle guide vanes in the turbine?

What is the name of the vanes that extract the remaining energy from the gas flow?

What is the name of the vanes that extract the remaining energy from the gas flow?

What is the purpose of the turbine casing?

What is the purpose of the turbine casing?

What is a turbine stage composed of?

What is a turbine stage composed of?

What is the function of the shroud in a turbine?

What is the function of the shroud in a turbine?

What is the typical location of a turbine assembly?

What is the typical location of a turbine assembly?

What is the primary function of nozzle guide vanes in a gas turbine engine?

What is the primary function of nozzle guide vanes in a gas turbine engine?

What materials are commonly used to construct nozzle guide vanes?

What materials are commonly used to construct nozzle guide vanes?

What is the purpose of the gaps between shroud segments in a nozzle guide vane assembly?

What is the purpose of the gaps between shroud segments in a nozzle guide vane assembly?

What type of manufacturing is being used to reduce the weight of nozzle guide vanes?

What type of manufacturing is being used to reduce the weight of nozzle guide vanes?

What is the relationship between nozzle guide vane types and turbine blade types?

What is the relationship between nozzle guide vane types and turbine blade types?

How many types of turbine blade and nozzle configurations are in common use today?

How many types of turbine blade and nozzle configurations are in common use today?

What is the main reason for twisting the nozzle and blades of the turbine?

What is the main reason for twisting the nozzle and blades of the turbine?

What is the purpose of the stagger angle in the turbine blades?

What is the purpose of the stagger angle in the turbine blades?

Why are shrouds often used in lower speed turbine locations?

Why are shrouds often used in lower speed turbine locations?

What is the result of the energy absorption during the reaction through the turbine blades?

What is the result of the energy absorption during the reaction through the turbine blades?

What type of turbine design is used in modern turbines for optimum energy conversion to torque?

What type of turbine design is used in modern turbines for optimum energy conversion to torque?

Why are open tip blades often used in high-speed turbine wheels?

Why are open tip blades often used in high-speed turbine wheels?

What is the main reason why the method of attaching turbine blades to the turbine disc is of considerable importance?

What is the main reason why the method of attaching turbine blades to the turbine disc is of considerable importance?

What type of machining is required for fir tree fixing to ensure that the loading is shared by all the serrations?

What type of machining is required for fir tree fixing to ensure that the loading is shared by all the serrations?

What stiffens the blade root when the engine is stationary and cold?

What stiffens the blade root when the engine is stationary and cold?

What is the purpose of the special tabs, pins, rivets, or locking plates in fir tree fixing?

What is the purpose of the special tabs, pins, rivets, or locking plates in fir tree fixing?

What is the component of the turbine engine that has provision for the attachment of blades around its circumference?

What is the component of the turbine engine that has provision for the attachment of blades around its circumference?

What is the result of the centrifugal loading when the turbine is rotating?

What is the result of the centrifugal loading when the turbine is rotating?

Flashcards are hidden until you start studying

Study Notes

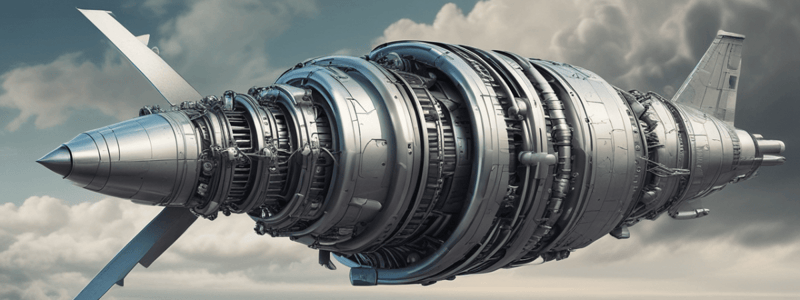

Turbine Section

- The turbine provides power to drive the compressor and accessories, and also provides shaft power for a propeller or rotor in engines that don't use solely a jet for propulsion.

- The turbine extracts energy from the hot gases released from the combustion system and expands them to a lower pressure and temperature.

- Energy is extracted by passing the airflow over a set of aerofoil-shaped blades.

- High stresses are involved in this process, and for efficient operation, the turbine blade tips may rotate at speeds up to 1500 ft/s.

- The continuous flow of gas to which the turbine is exposed may have an entry temperature between 850 and 1700 °C and may reach a velocity of 2500 ft/s in parts of the turbine.

Radial Inflow Turbine

- Radial inflow turbines are used in ancillary equipment such as gas turbine compressors, Auxiliary Power Units (APUs), air turbine motors, and some types of turbo superchargers.

- The design and construction of the turbine center on a disc having radially disposed vanes machined into its face.

- The main difference is the fitting of a set of vanes to the rear face of the turbine wheel, known as exducer vanes, which increase the length of the turbine vanes and improve efficiency.

- Gas flow through the turbine first enters through a ring of stationary nozzle guide vanes, then flows to the eye of the turbine and across the exducer vanes, and exits at atmospheric pressure through the jet pipe.

Axial Flow Turbine

- The basic components of the turbine are:

- Turbine case

- Stator (also called the nozzle)

- Shroud

- Rotor

- A disc and a number of turbine blades make up a turbine rotor, and a nozzle and a rotor make up a turbine stage.

- The rotating assembly is supported on bearings mounted in the turbine casing.

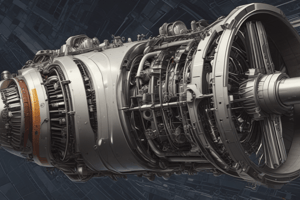

Turbine Case

- The turbine casing encloses the turbine rotor and stator assembly, giving either direct or indirect support to the stator elements.

- A typical case has flanges on both ends that provide a means of attaching the turbine section to the combustion section and the exhaust assembly.

Nozzle Guide Vanes (NGVs)

- NGVs direct flow onto turbine blades and require extremely high heat resistance.

- They are generally constructed from alloys of cobalt, nickel, and chrome.

- Advances in NGV designs include nickel alloy with ceramic coatings, Ceramic Matrix Composites (CMCs), and adaptive manufacturing (3D printing).

- CMCs and adaptive manufacturing are reducing the weight of NGVs by up to two-thirds and increasing the exhaust temperature, thereby increasing the efficiency of the engine.

Turbine Blades

- Three types of turbine blade and nozzle configurations are in common use today:

- Impulse

- Reaction

- Impulse/reaction

- The modern turbines all use the impulse/reaction design for optimum energy conversion to torque, to the propeller or to thrust from the fan.

- Turbine blades are either open at the tip or fitted with interlocking or fixed shrouds.

- Blade and NGV thermal barrier coatings are used to improve efficiency.

Energy Transfer

- The nozzle and blades of the turbine are twisted, with the blades having a stagger angle that is greater at the tip than the root.

- The reasons for this twist are to make the gas flow from the combustion section do equal work at all positions along the length of the blade and to ensure that the flow enters the exhaust system with a uniform axial velocity.

Blade Attachment Methods

- The method of attaching turbine blades to the turbine disc is of considerable importance since the stress in the disc around the attachment point or in the blade root greatly affects the limiting rim speed.

- Fir tree fixing is now used on the majority of gas turbine engines, involving very accurate machining to ensure that the loading is shared by all the serrations.

- The blade is free in the serrations when the engine is stationary and cold and is stiffened in the root by thermal expansion of the disc and blades and centrifugal loading when the turbine is rotating.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.