Podcast

Questions and Answers

What is a characteristic feature of ductile materials compared to brittle materials?

What is a characteristic feature of ductile materials compared to brittle materials?

- Ductile materials have a lower toughness than brittle materials.

- Ductile materials are always stronger than brittle materials.

- Ductile materials show significant plastic deformation before failure. (correct)

- Ductile materials fracture at lower stress levels.

Which theory of failure primarily accounts for multi-axial stress states?

Which theory of failure primarily accounts for multi-axial stress states?

- Von Mises theory (correct)

- Tresca theory

- Mohr's Circle theory

- Hooke's Law

What is the main variable affecting fatigue strength as represented in the S-N diagram?

What is the main variable affecting fatigue strength as represented in the S-N diagram?

- Fatigue limit

- Load frequency

- Mean stress (correct)

- Material density

Which of the following tools is commonly used to design welded pressure vessels?

Which of the following tools is commonly used to design welded pressure vessels?

In the context of stress concentration, which geometric feature is likely to amplify stress in a shaft?

In the context of stress concentration, which geometric feature is likely to amplify stress in a shaft?

What is the main purpose of the factor of safety in mechanical design?

What is the main purpose of the factor of safety in mechanical design?

What is a characteristic of fatigue under low cycle conditions?

What is a characteristic of fatigue under low cycle conditions?

What is the primary concern when designing threaded fasteners under dynamic loading conditions?

What is the primary concern when designing threaded fasteners under dynamic loading conditions?

What is the yield strength of FeE 250 steel?

What is the yield strength of FeE 250 steel?

What percentage of carbon is present in specification 25Cr4Mo2?

What percentage of carbon is present in specification 25Cr4Mo2?

Which element is associated with a factor of 100 in alloy steels?

Which element is associated with a factor of 100 in alloy steels?

What is the percentage composition of manganese in 20C12Pb15?

What is the percentage composition of manganese in 20C12Pb15?

In high alloy steels, what is the carbon percentage in the specification X15Cr25Ni12?

In high alloy steels, what is the carbon percentage in the specification X15Cr25Ni12?

Which of the following elements is indicated to enhance strength in medium alloy steels with a factor of 10?

Which of the following elements is indicated to enhance strength in medium alloy steels with a factor of 10?

What is the tensile strength specified for Fe 360 steel?

What is the tensile strength specified for Fe 360 steel?

How many types of loads can mechanical components be subjected to, according to the content?

How many types of loads can mechanical components be subjected to, according to the content?

What is the required diameter of the shaft with an ultimate tensile strength of 400 MPa and a factor of safety of 2?

What is the required diameter of the shaft with an ultimate tensile strength of 400 MPa and a factor of safety of 2?

How does the thickness 't' of a member with a 50 mm hole relate to the maximum allowable stress compared to a solid member?

How does the thickness 't' of a member with a 50 mm hole relate to the maximum allowable stress compared to a solid member?

What is the maximum stress experienced in a section of a shaft with a 2.5 mm transverse hole and a bending moment of 1.5 kNm?

What is the maximum stress experienced in a section of a shaft with a 2.5 mm transverse hole and a bending moment of 1.5 kNm?

What effect does the transverse hole have on the section's stress concentration factor and maximum stress?

What effect does the transverse hole have on the section's stress concentration factor and maximum stress?

If the hole was not present in the shaft, what would be the expected factor of safety (FOS) for the same bending moment of 1.5 kNm in a hot rolled carbon steel material?

If the hole was not present in the shaft, what would be the expected factor of safety (FOS) for the same bending moment of 1.5 kNm in a hot rolled carbon steel material?

What is the factor of safety applied for the mild steel shaft in the bending moment scenario?

What is the factor of safety applied for the mild steel shaft in the bending moment scenario?

What is the yield point strength of the mild steel used for the shaft?

What is the yield point strength of the mild steel used for the shaft?

Which theory is used to determine the maximum torque that causes failure of the shaft?

Which theory is used to determine the maximum torque that causes failure of the shaft?

What is the tensile strength of the plane carbon steel 45C8 used for the crank shaft?

What is the tensile strength of the plane carbon steel 45C8 used for the crank shaft?

What is a key limitation of conventional design equations for stress?

What is a key limitation of conventional design equations for stress?

What phenomenon occurs due to the presence of discontinuities in a component's cross-section?

What phenomenon occurs due to the presence of discontinuities in a component's cross-section?

In the photo-elasticity technique, what is used to observe stress distribution?

In the photo-elasticity technique, what is used to observe stress distribution?

What effect is observed near a circular hole in a plate subjected to tensile stress?

What effect is observed near a circular hole in a plate subjected to tensile stress?

What does the maximum principal strain theory indicate about failure?

What does the maximum principal strain theory indicate about failure?

In total strain energy theory, what condition leads to failure?

In total strain energy theory, what condition leads to failure?

What formula represents the failure condition in the maximum principal strain theory?

What formula represents the failure condition in the maximum principal strain theory?

Which aspect is not considered in total strain energy theory?

Which aspect is not considered in total strain energy theory?

Under what condition does failure occur in a bi-axial stress scenario according to principal strain theory?

Under what condition does failure occur in a bi-axial stress scenario according to principal strain theory?

What is the significance of Poisson's ratio in determining failure according to the theories of failure?

What is the significance of Poisson's ratio in determining failure according to the theories of failure?

What happens when the total strain energy exceeds the yield point energy according to Haigh's theory?

What happens when the total strain energy exceeds the yield point energy according to Haigh's theory?

When determining root diameter of a bolt, what is a key factor that needs to be considered?

When determining root diameter of a bolt, what is a key factor that needs to be considered?

Flashcards are hidden until you start studying

Study Notes

Steel Specifications

- Fe 360 has a tensile strength of 360 MPa.

- FeE 250 has a yield strength of 250 MPa.

Plain Carbon Steel Composition

- 55C4: Carbon 0.55%, Manganese 0.4%.

- 40C8: Carbon range 0.35-0.45%, Manganese range 0.7-0.9%.

Free Cutting Steel Composition

- 25C12S14: Carbon 0.25%, Manganese 1.2%, Sulphur 0.14%.

- 20C12Pb15: Carbon 0.2%, Manganese 1.2%, Lead 0.15%.

- Elements like S, Pb, Se, Te may be included based on presence.

Low & Medium Alloy Steels

- Total alloying elements must not exceed 10%.

- Significant alloying elements and their factors include:

- Cr, Co, Ni, Mn, Si, W: factor 4.

- Al, Be, V, Pb, Cu, Nb, Ti, Ta, Zr, Mo: factor 10.

- P, S, N: factor 100.

- Example:

- 25Cr4Mo2: Carbon 0.25%, Chromium 1%, Molybdenum 0.2%.

- 40Ni8Cr8V2: Carbon 0.4%, Nickel 2%, Chromium 2%, Vanadium 0.2%.

High Alloy Steels

- Total alloying elements exceed 10%.

- Example: X15Cr25Ni12 comprises Carbon 0.15%, Chromium 25%, Nickel 12%.

Principal Stresses and Theories of Failure

- Mechanical components can be subjected to multiple loading types.

- Theories of failure include:

- Maximum principal stress theory.

- Maximum principal strain theory (St. Venant’s theory).

- Total strain energy theory (Haigh’s theory).

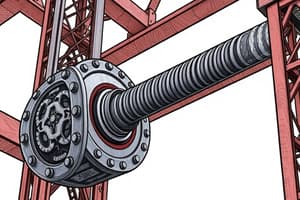

Stress Concentration

- Stress concentration arises from geometric discontinuities or irregularities in components.

- This leads to localized high stresses, often significantly higher than theoretical predictions.

- An experimental method for evaluating stress distribution uses photoelasticity, displaying stress distributions around holes.

Mechanical Design Concepts

- Ductile vs. brittle fracture descriptions.

- Key stress-related phenomena: strain energy, toughness, hardness, creep.

- Load types: axial, bending, torsional.

- Design applications involving shafts, keys, riveted joints, welded joints, threaded fasteners, and power screws.

Practical Applications

- Calculations involving principal stresses, shear stresses, and dimensions of structural elements are critical for design safety.

- Commonly assessed factors include yield strengths, factors of safety, and maximum torque limits when analyzing structural integrity.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.