Podcast

Questions and Answers

Which of these is NOT a key characteristic of soldering, as opposed to welding?

Which of these is NOT a key characteristic of soldering, as opposed to welding?

- A molten metallic filler material is used to join two materials.

- The parent materials melt during the process. (correct)

- The process utilizes a filler material that melts below 400°C.

- The filler material has a lower melting point than the materials being joined.

In which industry is soldering most commonly employed?

In which industry is soldering most commonly employed?

- Textile

- Construction

- Electronics Assembly (correct)

- Automotive

What is the primary distinction between soldering and brazing?

What is the primary distinction between soldering and brazing?

- The materials being joined.

- The temperature at which the filler material melts. (correct)

- The application of the process.

- The type of filler material used.

What is the approximate annual quantity of electronic components sold globally?

What is the approximate annual quantity of electronic components sold globally?

Besides electronics assembly, where else is soldering traditionally used?

Besides electronics assembly, where else is soldering traditionally used?

What is the primary reason that soldering is so widely used in electronics assembly?

What is the primary reason that soldering is so widely used in electronics assembly?

Why are soldered joints often found inside electronic components as well?

Why are soldered joints often found inside electronic components as well?

Which of the following industries does NOT typically utilize soldering?

Which of the following industries does NOT typically utilize soldering?

Which of the following is NOT a typical substrate material for PCBs?

Which of the following is NOT a typical substrate material for PCBs?

What is the typical thickness of a standard 1oz copper foil used in PCB manufacturing?

What is the typical thickness of a standard 1oz copper foil used in PCB manufacturing?

Why is it important to use entrance and exit materials during PCB drilling?

Why is it important to use entrance and exit materials during PCB drilling?

What is the primary reason for using woven glass fibers in PCB substrate materials?

What is the primary reason for using woven glass fibers in PCB substrate materials?

What type of etching process is used for single crystal materials like silicon in PCB manufacturing?

What type of etching process is used for single crystal materials like silicon in PCB manufacturing?

What is the main purpose of the alignment marks used in PCB lithography?

What is the main purpose of the alignment marks used in PCB lithography?

Which of the following methods is NOT typically used for creating holes in PCBs?

Which of the following methods is NOT typically used for creating holes in PCBs?

During positive photoresist lithography, which areas are exposed to UV light?

During positive photoresist lithography, which areas are exposed to UV light?

What is the relationship between the exposure time, sensitivity, and intensity of the UV light in photolithography?

What is the relationship between the exposure time, sensitivity, and intensity of the UV light in photolithography?

Which type of etching creates a smooth, non-directional etch profile in the PCB?

Which type of etching creates a smooth, non-directional etch profile in the PCB?

What is the primary advantage of flip-chip assembly over wire bonding?

What is the primary advantage of flip-chip assembly over wire bonding?

Which of the following materials is commonly used to encapsulate integrated circuits (ICs) in a package?

Which of the following materials is commonly used to encapsulate integrated circuits (ICs) in a package?

What is the primary purpose of underfill in flip-chip assembly?

What is the primary purpose of underfill in flip-chip assembly?

Which of the following technologies, besides wire bonding, is commonly used for level one interconnection?

Which of the following technologies, besides wire bonding, is commonly used for level one interconnection?

What is the purpose of the "under bump metallisation" (UBM) layer in a flip-chip package?

What is the purpose of the "under bump metallisation" (UBM) layer in a flip-chip package?

What process is used to expose the internal components of an IC package for inspection?

What process is used to expose the internal components of an IC package for inspection?

In flip-chip assembly, what is the primary factor that contributes to stress on the solder joint during temperature cycles?

In flip-chip assembly, what is the primary factor that contributes to stress on the solder joint during temperature cycles?

Which of the following is NOT a key advantage of flip-chip assembly?

Which of the following is NOT a key advantage of flip-chip assembly?

What role do local fiducials play in PCB manufacturing?

What role do local fiducials play in PCB manufacturing?

Which of the following is NOT a process commonly associated with PCB manufacturing?

Which of the following is NOT a process commonly associated with PCB manufacturing?

Which market sector does NOT typically involve consumer electronics?

Which market sector does NOT typically involve consumer electronics?

What is one primary purpose of the various PCB assembly processes mentioned?

What is one primary purpose of the various PCB assembly processes mentioned?

Which of these components is least likely to be categorized under service products in electronics?

Which of these components is least likely to be categorized under service products in electronics?

What is often included in the interconnection requirements of PCBs?

What is often included in the interconnection requirements of PCBs?

Which process is primarily used to create patterns on PCBs?

Which process is primarily used to create patterns on PCBs?

Which of the following best describes the changes in electronics manufacturing over time?

Which of the following best describes the changes in electronics manufacturing over time?

What is the purpose of applying heat during the reflow soldering process?

What is the purpose of applying heat during the reflow soldering process?

What characteristic of solder paste makes it suitable for stencil printing?

What characteristic of solder paste makes it suitable for stencil printing?

Which statement about the reflow process using convection or IR soldering is true?

Which statement about the reflow process using convection or IR soldering is true?

What is a key difference between reflow soldering and mass soldering?

What is a key difference between reflow soldering and mass soldering?

During the cooling phase of soldering, what is the primary effect on the solder?

During the cooling phase of soldering, what is the primary effect on the solder?

What is the typical temperature range for maintaining a pot of molten solder in mass soldering?

What is the typical temperature range for maintaining a pot of molten solder in mass soldering?

What function does the stencil serve in the solder paste application process?

What function does the stencil serve in the solder paste application process?

Why is it important to remove oxide and dross from solder during mass soldering?

Why is it important to remove oxide and dross from solder during mass soldering?

What does Moore's Law specifically relate to?

What does Moore's Law specifically relate to?

What does Rent’s Rule suggest about circuit complexity?

What does Rent’s Rule suggest about circuit complexity?

In the equation I = bCp from Rent’s Rule, what does 'I' represent?

In the equation I = bCp from Rent’s Rule, what does 'I' represent?

According to microprocessor trends, what has been the trend regarding pin count?

According to microprocessor trends, what has been the trend regarding pin count?

What is the significance of Moore’s Law in the context of technology?

What is the significance of Moore’s Law in the context of technology?

What year marks the introduction of the first microprocessor, the Intel i4004?

What year marks the introduction of the first microprocessor, the Intel i4004?

Which factor does 'p' represent in Rent’s Rule?

Which factor does 'p' represent in Rent’s Rule?

What is the minimum feature size of the Intel i4004 microprocessor?

What is the minimum feature size of the Intel i4004 microprocessor?

Flashcards

Local Fiducials

Local Fiducials

The use of vision systems to accurately locate the position of components on a Printed Circuit Board (PCB) during assembly.

Internet of Things (IoT)

Internet of Things (IoT)

A widely used, interconnected network of physical objects that can collect and exchange data through the internet.

PCB Etching

PCB Etching

The process of removing excess metallic material from a Printed Circuit Board (PCB), leaving behind the desired circuitry.

Photolithography

Photolithography

Signup and view all the flashcards

Electronics Manufacturing

Electronics Manufacturing

Signup and view all the flashcards

PCB Manufacturing

PCB Manufacturing

Signup and view all the flashcards

Contamination Control

Contamination Control

Signup and view all the flashcards

Yield

Yield

Signup and view all the flashcards

Glass reinforced polyimide

Glass reinforced polyimide

Signup and view all the flashcards

PTFE

PTFE

Signup and view all the flashcards

Non-reinforced polyimide/polyester films

Non-reinforced polyimide/polyester films

Signup and view all the flashcards

Woven Glass Fibre

Woven Glass Fibre

Signup and view all the flashcards

Copper foil/film

Copper foil/film

Signup and view all the flashcards

Ounce (oz)

Ounce (oz)

Signup and view all the flashcards

Drilling

Drilling

Signup and view all the flashcards

PCB Drill Bits

PCB Drill Bits

Signup and view all the flashcards

Multi-spindle PCB Drilling machine

Multi-spindle PCB Drilling machine

Signup and view all the flashcards

Etching

Etching

Signup and view all the flashcards

Soldering

Soldering

Signup and view all the flashcards

Solder

Solder

Signup and view all the flashcards

Brazing

Brazing

Signup and view all the flashcards

Welding

Welding

Signup and view all the flashcards

Electronic Assembly

Electronic Assembly

Signup and view all the flashcards

Printed Circuit Board (PCB)

Printed Circuit Board (PCB)

Signup and view all the flashcards

Soldering Process

Soldering Process

Signup and view all the flashcards

Solder Paste

Solder Paste

Signup and view all the flashcards

Stencil Printing

Stencil Printing

Signup and view all the flashcards

Solder Paste Stencil

Solder Paste Stencil

Signup and view all the flashcards

Reflow Soldering

Reflow Soldering

Signup and view all the flashcards

Reflow Oven/Furnace

Reflow Oven/Furnace

Signup and view all the flashcards

Temperature Profile

Temperature Profile

Signup and view all the flashcards

Mass Soldering

Mass Soldering

Signup and view all the flashcards

Flux

Flux

Signup and view all the flashcards

What is Moore's Law?

What is Moore's Law?

Signup and view all the flashcards

What is Rent's Rule?

What is Rent's Rule?

Signup and view all the flashcards

What is the trend in microprocessor pin count?

What is the trend in microprocessor pin count?

Signup and view all the flashcards

What are interconnection hierarchies?

What are interconnection hierarchies?

Signup and view all the flashcards

What is the first microprocessor?

What is the first microprocessor?

Signup and view all the flashcards

What is minimum feature size on a microprocessor?

What is minimum feature size on a microprocessor?

Signup and view all the flashcards

What are bond pads on a microprocessor?

What are bond pads on a microprocessor?

Signup and view all the flashcards

What was the minimum feature size of the first microprocessor?

What was the minimum feature size of the first microprocessor?

Signup and view all the flashcards

Wire bonding

Wire bonding

Signup and view all the flashcards

Decapping

Decapping

Signup and view all the flashcards

PCB

PCB

Signup and view all the flashcards

Level one interconnection

Level one interconnection

Signup and view all the flashcards

Wirebond

Wirebond

Signup and view all the flashcards

Flip Chip

Flip Chip

Signup and view all the flashcards

Underfill

Underfill

Signup and view all the flashcards

Study Notes

Electronics Manufacturing

- Electronics manufacturing is a large, complex, and rapidly evolving industry

- Key processes include lithography, drilling, etching, and plating

- Interconnection requirements/hierarchies are crucial for complex products

- Component types and their manufacture are essential factors in electronics assembly

- PCB manufacturing processes are critical to production

- Soldering processes connect components to PCBs

- Contamination control, yield, and testing are crucial to high-quality products

Introduction to Electronics Manufacturing

- Electronic products cover a wide range of applications, including consumer, transport, medical, military, industrial, and telecommunications sectors

- Consumer electronics encompass various devices, such as smartphones, TVs, and gaming consoles

- Other examples of appliances are washing machines and cam timers

- The transport sector uses electronics in aircraft, cars, and other vehicles, with controls for features like braking systems, and electronic throttle control

- Telecommunications use electronics for data centers and network infrastructure, with specialized applications like fibre optics

Technology Trends

- The rapid evolution of electronics is driven by technology trends, emphasizing both speed and functional requirements

- Comparing electronics to other technologies reveals significant advancements, like faster speeds, and smaller forms

- These historical trends show radical changes in speed, size and cost of items, and were made possible thanks to the development of valves to transistors, and the invention of integrated circuits

Interconnection Requirements/Hierarchies

- Interconnection hierarchies are crucial in electronics manufacturing, as they connect components in layers

- Level 1 interconnections: connect components to the outside world

- Level 2 interconnections: connect these components to printed circuit boards (PCBs)

Component Types and Their Manufacture

- There are two main categories of electrically-based components: Passive and Active

- Passive components include resistors, capacitors, and inductors

- Active components include diodes, transistors, and integrated circuits (ICs)

- Various physical forms of components exist, based on mounting method

PCB Manufacturing Processes

- PCB materials are essential to production, particularly substrates and conductors, including copper foil

- Lithographic processes (like imaging, etching, and plating) are crucial for creating the necessary circuits on PCBs

- Drilling prepares holes for the electrical connections

- The manufacturing of single-sided, double-sided plated-through-hole(PTH) and multilayer PCBs have differing steps, and need varying levels of accuracy and complexity

- There are alternative hole-formation processes, such as punching, moulding, and laser drilling

- Routing and cutting out PCBs is another step

- Exposure methods for photoresist include contact, proximity and projection methods

- Contrast in photoresist determines response to varying exposures

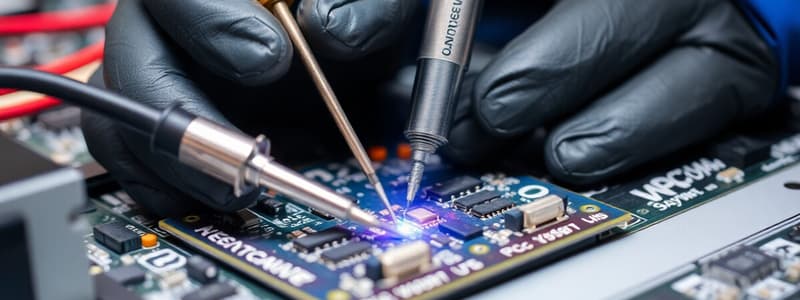

Soldering Processes

- Solder alloys are commonly used for joins, and include elements like tin, lead, copper, and others

- Intermetallics must be present in good solder joints, but need to be of a controlled thickness

- Forms of solder include wire, paste, and bulk

- Soldering processes encompass hand soldering, reflow soldering, and mass soldering

- Various considerations are essential in safe operating areas, such as temperature thresholds and durations during soldering, flux activity, and the use of protective measures

Contamination Control, Yield, and Testing

- Yield calculations consider the exponential distribution of defects in each step of electronics manufacturing

- Cleanliness in electronics manufacturing is crucial for preventing defects

- Cleanrooms are designed to minimize contamination, with features like clean materials and air systems

- Inspection and tests are done regularly and across all production phases to ensure high quality

Other Relevant Topics

- Moore's Law is a key concept, referring to the steady increase in the number of transistors in a chip every two years

- Metal Cutting Precision and SKF are examples of factors that have greatly changed over time, and thus reflect the increasing importance in high precision manufacturing

- Different technologies result from innovations and advances in electronics, like better memory, and improved circuit design.

- Examples include a typical desktop computer assembly in 1999 and a comparison of different components and how they have changed since then

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.