Podcast

Questions and Answers

What is the main limitation of the processes described before?

What is the main limitation of the processes described before?

- They cannot produce shiny bearing surfaces

- They require manual labor for finishing

- They cannot be used for secondary operations

- They cannot make parts to their final dimensions and surface finish (correct)

What kind of operations are being referred to?

What kind of operations are being referred to?

- Quality control operations

- Secondary and finishing operations (correct)

- Packaging and shipping operations

- Primary manufacturing operations

What is the importance of surface finish in part production?

What is the importance of surface finish in part production?

- It affects the part's durability

- It affects the part's weight

- It affects the part's functionality (correct)

- It affects the part's aesthetic appeal

What does the text imply about the processes described before?

What does the text imply about the processes described before?

What is the context of the part production being discussed?

What is the context of the part production being discussed?

What is the term for the angle between the major flank and the cutting plane?

What is the term for the angle between the major flank and the cutting plane?

What is the main goal of machining by cutting?

What is the main goal of machining by cutting?

Which of the following is NOT a type of material used for machining tools?

Which of the following is NOT a type of material used for machining tools?

In the context of machining, what is the 'workpiece'?

In the context of machining, what is the 'workpiece'?

What is the direction in which the cutting tool moves during machining?

What is the direction in which the cutting tool moves during machining?

What is the primary effect of reducing friction between the cutting tool and work-piece?

What is the primary effect of reducing friction between the cutting tool and work-piece?

What is the result of reducing the friction between the cutting tool and work-piece on the tool's temperature?

What is the result of reducing the friction between the cutting tool and work-piece on the tool's temperature?

What is the primary benefit of reducing the friction between the cutting tool and work-piece?

What is the primary benefit of reducing the friction between the cutting tool and work-piece?

What happens to the wear of the tool when friction between the cutting tool and work-piece is reduced?

What happens to the wear of the tool when friction between the cutting tool and work-piece is reduced?

What are the two effects of reducing friction between the cutting tool and work-piece?

What are the two effects of reducing friction between the cutting tool and work-piece?

What is the tool angle a measure of?

What is the tool angle a measure of?

What is the flank in relation to the tool?

What is the flank in relation to the tool?

What is the wedge in the context of the tool?

What is the wedge in the context of the tool?

What is the focus of the description provided?

What is the focus of the description provided?

What is the critical aspect of the tool face in relation to the flank?

What is the critical aspect of the tool face in relation to the flank?

What is the primary purpose of a face plate in a turning operation?

What is the primary purpose of a face plate in a turning operation?

What type of chuck is typically used for holding symmetrical workpieces?

What type of chuck is typically used for holding symmetrical workpieces?

What is the primary difference between straight turning and taper turning?

What is the primary difference between straight turning and taper turning?

What is the formula to calculate the average diameter of the ring in a turning operation?

What is the formula to calculate the average diameter of the ring in a turning operation?

What is the unit of cutting speed in a turning operation?

What is the unit of cutting speed in a turning operation?

What is the formula to calculate the cutting time in a turning operation?

What is the formula to calculate the cutting time in a turning operation?

What is the primary purpose of knurling in a turning operation?

What is the primary purpose of knurling in a turning operation?

What is the term for the process of cutting a groove on the external surface of a workpiece?

What is the term for the process of cutting a groove on the external surface of a workpiece?

Study Notes

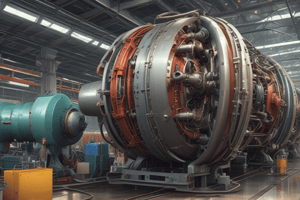

Secondary and Finishing Operations

- Shiny bearing surfaces of a part cannot be made to their final dimensions and surface finish by any of the processes described before.

Tool Materials

- Alloy tool steel

- High speed steel

- Carbides

- Ceramics

- Diamond

Machining by Cutting

- Cutting direction is involved in the process

- Depth to be cut is a factor

- Tool and workpiece are involved in the process

Clearance (Relief) Angle

- It is the angle between the major flank and the cutting plane

- Reduces friction between the cutting tool and work-piece, reducing heat and wear of the tool

Tool (Wedge) Angle

- It is the angle between the tool face and flank

Work Piece Holding

- Face plate can be used

- 4-jaw chuck can be used

- 3-jaw chuck can be used

- Between two centers can be used

Tool Holding

- Tool post can be used

Main Turning Operations

- Straight turning: involves multiple depths of cut

- Taper turning: involves a tapered shape

- Turning and external grooving: involves cutting a groove

- Facing: involves cutting a flat surface

- Cutting with a form tool: involves cutting a specific shape

- Boring and internal grooving: involves cutting a hole and a groove

- Drilling: involves cutting a hole

- Recessing and Cutting off: involves cutting a recess and cutting off a piece

- Threading: involves cutting a thread

- Knurling: involves cutting a textured surface

The Turning Process

- The average diameter of the ring can be calculated using Davg = (D+d) / 2

- The cutting speed V (m/min) can be calculated using v = (πDN) / 1000

- The cutting time can be calculated using t = l / v

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz covers the processes that cannot be used to achieve final dimensions and surface finish of a part. It explores the limitations of various manufacturing processes.