Podcast

Questions and Answers

When should SCBA be inspected after use?

When should SCBA be inspected after use?

- Before cleaning and disinfection

- After cleaning and disinfection (correct)

- Only if there are visible contaminants

- Weekly during routine maintenance

Who is responsible for inspecting their assigned SCBA daily?

Who is responsible for inspecting their assigned SCBA daily?

- The firefighter captain

- All personnel (correct)

- The Equipment Manager

- Designated safety officer

What should you check for during the visual inspection of all SCBA components?

What should you check for during the visual inspection of all SCBA components?

- Correct configuration of buttons

- Presence of manufacturer labels

- Signs of deterioration, dirt, cracks, or debris (correct)

- Proper inflation of the air cylinder

In the inspection of the facepiece, what indicates a defect?

In the inspection of the facepiece, what indicates a defect?

Which condition would NOT be an appropriate step for checking the regulator?

Which condition would NOT be an appropriate step for checking the regulator?

What should be ensured regarding the exhalation valve during facepiece inspection?

What should be ensured regarding the exhalation valve during facepiece inspection?

What should you do before installing the quick connect coupling?

What should you do before installing the quick connect coupling?

What specific aspect should you check if the SCBA is equipped with a quick connect hose?

What specific aspect should you check if the SCBA is equipped with a quick connect hose?

How do you release the quick connect from the cylinder valve?

How do you release the quick connect from the cylinder valve?

What must be checked on the cylinder approval sticker?

What must be checked on the cylinder approval sticker?

What pressure should the cylinder have at a minimum?

What pressure should the cylinder have at a minimum?

What needs to be ensured regarding the power module and pressure reducer in the carrier assembly?

What needs to be ensured regarding the power module and pressure reducer in the carrier assembly?

Which of the following should be checked for damage in the control module?

Which of the following should be checked for damage in the control module?

What indicates that the quick connect coupling is properly attached to the cylinder valve adapter?

What indicates that the quick connect coupling is properly attached to the cylinder valve adapter?

What should you listen for when allowing the control module to remain motionless for approximately 20 seconds?

What should you listen for when allowing the control module to remain motionless for approximately 20 seconds?

How do you reset the full PASS alarm?

How do you reset the full PASS alarm?

What should be verified when the PASS pre-alarm sounds?

What should be verified when the PASS pre-alarm sounds?

What should you do after pressing the alarm button on the control module?

What should you do after pressing the alarm button on the control module?

How can you ensure the proper attachment of the regulator to the facepiece?

How can you ensure the proper attachment of the regulator to the facepiece?

What should you do to check the manual activation of the PASS alarm?

What should you do to check the manual activation of the PASS alarm?

What is the last step to ensure the speaker module is operating properly?

What is the last step to ensure the speaker module is operating properly?

What is the first step to be performed when releasing the pressure?

What is the first step to be performed when releasing the pressure?

What should you do immediately after removing the facepiece from the face?

What should you do immediately after removing the facepiece from the face?

At what pressure should the control module pressure reading drop below when venting the pressure?

At what pressure should the control module pressure reading drop below when venting the pressure?

Which LED display should be present in HUD at the appropriate pressure while venting the system?

Which LED display should be present in HUD at the appropriate pressure while venting the system?

Which lights should be flashing red when the primary low pressure warning device is alarming?

Which lights should be flashing red when the primary low pressure warning device is alarming?

At what air pressure should the alarms continue?

At what air pressure should the alarms continue?

What should be done when the system pressure falls below 200 psi?

What should be done when the system pressure falls below 200 psi?

How many times should the reset button be pressed to turn the control module off?

How many times should the reset button be pressed to turn the control module off?

What is the final step in the procedure for releasing the pressure?

What is the final step in the procedure for releasing the pressure?

Flashcards are hidden until you start studying

Study Notes

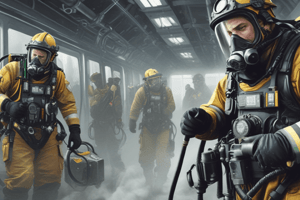

Operational Check

- SCBA inspection is part of the daily check-off and must be performed after cleaning and disinfection.

- All personnel are responsible for inspecting their assigned SCBA daily, and this responsibility cannot be delegated.

- The SCBA inspection consists of a visual inspection and a functional test.

All Components

- Inspect all components for deterioration, dirt, cracks, debris, tears, holes, stickiness, signs of heat or chemical related damage, or other visible signs of damage.

- Inspect all straps for tears, cuts, wear, abrasion, missing buckles or straps.

Facepiece

- Inspect the lens for cracks, scratches, deformation, and color change.

- Check the facepiece rubber for a tight seal and secure fit to the lens ring.

- Ensure the exhalation valve is clean and operates easily.

- Inspect the facepiece inlet for damage and ensure the inhalation valve is in place.

- Inspect the nosecup to ensure the check valve is in place and the nosecup is secure to the component housing.

Regulator

- Ensure that moisture or debris is not present, especially inside the regulator and in the microphone ports.

- Inspect the o-ring and seal ring for damage or debris.

- Inspect the quick connect hose for deterioration, dirt, cracks, tears, or tackiness.

- Inspect the quick connect fittings and ensure they operate properly and are secured.

Pressure Reducer

- Inspect the high pressure relief valve for damage.

- Ensure the adapter on the cylinder valve is tight.

- Reattach the handwheel to the cylinder valve and push the quick connect coupling onto the cylinder valve adapter until an audible snap is heard.

Cylinder and Valve Assembly

- Check the hydrostatic test date on the cylinder approval sticker.

- Ensure the needle and gauge face on the cylinder valve gauge are clearly visible and not bent.

- Ensure the rubber boot is present on the cylinder valve.

- The cylinder must have a minimum pressure of 4050 PSI.

Carrier Assembly

- Operate the latch on the cylinder band to ensure it opens and closes properly and holds the cylinder securely.

- Ensure the unit identifier is present.

- Ensure the lumbar pad is attached securely.

- Ensure the power module and pressure reducer are secured to the back panel and lower cover.

Control Module

- Inspect the displays for cracks and other visible damage.

- Ensure the buttons are not damaged or missing.

- Inspect the hose assembly for secure attachment to the control module.

- Ensure the needle and gauge face on the gauge are clearly visible and not bent.

Power Module

- Verify proper function of the HUD, control module, power module, and low pressure warning device.

- Perform the PASS alarm operation guide with a full cylinder.

PASS Alarm Operation Guide

- Verify the proper function of the HUD, control module, power module, and low pressure warning device by observing the control module gauge and display when the alarms sound.

- Allow the control module to remain motionless for approximately 20 seconds to verify the power module sounds repeated tones of the PASS pre-alarm.

- Allow the control module to remain motionless until the full alarm sounds (30 seconds) to verify the power module sounds the tones of the PASS full alarm.

- Reset the PASS alarm by pressing the left reset button (green) on the side of the control module twice within approximately one second.

- To check the manual activation of the PASS alarm, press and hold the alarm button on the front of the control module until the alarm activates.

Procedure for Releasing the Pressure

- Press and hold the on/off button on the speaker module until the audible tone sounds and the unit turns ON.

- Push the regulator release buttons to ensure air flow stops.

- Remove the facepiece from the face and close the cylinder valve fully.

- Slowly open the bypass valve on the regulator to vent the pressure until the control module pressure reading drops below approximately 1575 PSI.

- Ensure a flashing red LED displays in HUD at the appropriate pressure, and the primary low pressure warning device is alarming.

- The alarms should continue until the air pressure is 200 psi or less.

- When the system pressure falls below 200 psi, turn the control module off by pressing the reset button (green) two times within approximately one second.

- Open the bypass valve slowly to release any remaining pressure in the system.

- Close the bypass valve and stow the SCBA.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.