Podcast

Questions and Answers

What protects the leading edge of wooden rotor blades from abrasion?

What protects the leading edge of wooden rotor blades from abrasion?

- Aluminum tip cap

- Aluminum pockets

- Stainless steel cap (correct)

- Fiberglass cloth

What is a distinct advantage of metal rotor blades?

What is a distinct advantage of metal rotor blades?

- They are lighter than wood blades

- They are more resistant to moisture damage

- They have better quality control during construction (correct)

- They are less expensive to manufacture

What is the purpose of the aluminum pockets on metal rotor blades?

What is the purpose of the aluminum pockets on metal rotor blades?

- To attach the blade to the rotor head

- To protect the blade from abrasion

- To improve the blade's aerodynamic profile (correct)

- To provide additional strength to the blade

What is a disadvantage of wooden rotor blades?

What is a disadvantage of wooden rotor blades?

What type of construction is common to all rotor blades?

What type of construction is common to all rotor blades?

What is the purpose of the steel cuff on metal rotor blades?

What is the purpose of the steel cuff on metal rotor blades?

What is the main reason why most wooden rotor blades are in matched pairs?

What is the main reason why most wooden rotor blades are in matched pairs?

What type of material is used to cover the exterior surface of a fiberglass rotor blade?

What type of material is used to cover the exterior surface of a fiberglass rotor blade?

What is the location of the blade tip?

What is the location of the blade tip?

What is the purpose of the blade tip cap?

What is the purpose of the blade tip cap?

What is the leading edge of the blade?

What is the leading edge of the blade?

Why is the leading edge of the blade thicker than the trailing edge?

Why is the leading edge of the blade thicker than the trailing edge?

Why is the leading edge of the blade covered with a hard cap or coating?

Why is the leading edge of the blade covered with a hard cap or coating?

What is the span of a rotor blade?

What is the span of a rotor blade?

Why is the span line important to blade repairers?

Why is the span line important to blade repairers?

What is a primary advantage of using a uniform planform for rotor blades?

What is a primary advantage of using a uniform planform for rotor blades?

What does a uniform blade design reduce in terms of production?

What does a uniform blade design reduce in terms of production?

How does a tapered planform blade differ in performance compared to a uniform planform?

How does a tapered planform blade differ in performance compared to a uniform planform?

What is a characteristic of most rotor blades in terms of twist?

What is a characteristic of most rotor blades in terms of twist?

Which material is commonly used for the skin of rotor blades?

Which material is commonly used for the skin of rotor blades?

What is the function of the blade root in a rotor blade?

What is the function of the blade root in a rotor blade?

Why are tapered planform blades not commonly used by manufacturers?

Why are tapered planform blades not commonly used by manufacturers?

What consequence arises if the blade angle remains constant along its length?

What consequence arises if the blade angle remains constant along its length?

What is the faying surface in bonding?

What is the faying surface in bonding?

Why do manufacturers avoid drilling holes in load-carrying parts of the blade?

Why do manufacturers avoid drilling holes in load-carrying parts of the blade?

What type of weights are placed into the leading edge of a blade for mass balance?

What type of weights are placed into the leading edge of a blade for mass balance?

What happens when weights in the blade are adjusted?

What happens when weights in the blade are adjusted?

What is a potential consequence of careless use of cleaning solvents on bonded joints?

What is a potential consequence of careless use of cleaning solvents on bonded joints?

Which weight type is typically located at the tip of the blade?

Which weight type is typically located at the tip of the blade?

What does adding spanwise weight to a blade do to the center of gravity?

What does adding spanwise weight to a blade do to the center of gravity?

When is a repairer allowed to move weights in helicopter blades?

When is a repairer allowed to move weights in helicopter blades?

What effect does subtracting weight have on the center of gravity?

What effect does subtracting weight have on the center of gravity?

What negative consequences can arise from blades failing to track correctly?

What negative consequences can arise from blades failing to track correctly?

How can tracking weights be used to retain blade track?

How can tracking weights be used to retain blade track?

What is a cheaper method to align rotor blades to the same plane of rotation?

What is a cheaper method to align rotor blades to the same plane of rotation?

What is the function of a trim tab during tracking operations?

What is the function of a trim tab during tracking operations?

Where is the trim tab typically located on a rotor blade?

Where is the trim tab typically located on a rotor blade?

What is one reason for adding tracking weights to helicopter blades?

What is one reason for adding tracking weights to helicopter blades?

What must happen for all rotor blades to fly in the same plane of rotation?

What must happen for all rotor blades to fly in the same plane of rotation?

What is the purpose of painting the bottom of the rotor blade black?

What is the purpose of painting the bottom of the rotor blade black?

What is the purpose of blade stations?

What is the purpose of blade stations?

What is the main advantage of a single-pocket or fairing blade?

What is the main advantage of a single-pocket or fairing blade?

What is the main advantage of a multiple-pocket or fairing blade?

What is the main advantage of a multiple-pocket or fairing blade?

What is the purpose of the internal structural components in a rotor blade?

What is the purpose of the internal structural components in a rotor blade?

What is bonding in the context of rotor blade construction?

What is bonding in the context of rotor blade construction?

Which type of rotor blade is typically used on large helicopters?

Which type of rotor blade is typically used on large helicopters?

Flashcards

Fiberglass Rotor Blade

Fiberglass Rotor Blade

A type of rotor blade with an exterior surface covered with resin-impregnated fiberglass cloth.

Wooden Rotor Blades

Wooden Rotor Blades

Rotor blades made of wood, commonly used in older helicopters.

Stainless Steel Cap on Wooden Blade

Stainless Steel Cap on Wooden Blade

A protective stainless steel cap covering the leading edge of a wooden rotor blade to prevent wear.

Matched Wooden Rotor Blades

Matched Wooden Rotor Blades

Signup and view all the flashcards

Abrasion Protection on Wooden Blades

Abrasion Protection on Wooden Blades

Signup and view all the flashcards

Quality Control of Metal Blades

Quality Control of Metal Blades

Signup and view all the flashcards

Aluminum Spar in Metal Blades

Aluminum Spar in Metal Blades

Signup and view all the flashcards

Individual Replacement of Metal Blades

Individual Replacement of Metal Blades

Signup and view all the flashcards

Rotor Blade Root

Rotor Blade Root

Signup and view all the flashcards

Rotor Blade Tip

Rotor Blade Tip

Signup and view all the flashcards

Leading Edge

Leading Edge

Signup and view all the flashcards

Leading Edge Cap

Leading Edge Cap

Signup and view all the flashcards

Trailing Edge

Trailing Edge

Signup and view all the flashcards

Rotor Blade Span

Rotor Blade Span

Signup and view all the flashcards

Span Line

Span Line

Signup and view all the flashcards

Span Line and Damage

Span Line and Damage

Signup and view all the flashcards

Uniform Planform

Uniform Planform

Signup and view all the flashcards

Negative Tip Twist

Negative Tip Twist

Signup and view all the flashcards

Tapered Planform

Tapered Planform

Signup and view all the flashcards

Blade-Element Theory

Blade-Element Theory

Signup and view all the flashcards

Blade Root

Blade Root

Signup and view all the flashcards

Rotor Blade Twist

Rotor Blade Twist

Signup and view all the flashcards

Rotor Blade Internal Structure

Rotor Blade Internal Structure

Signup and view all the flashcards

What is the blade bottom surface?

What is the blade bottom surface?

Signup and view all the flashcards

What are blade stations?

What are blade stations?

Signup and view all the flashcards

What is a single-pocket rotor blade?

What is a single-pocket rotor blade?

Signup and view all the flashcards

What is a multiple-pocket rotor blade?

What is a multiple-pocket rotor blade?

Signup and view all the flashcards

What are the internal structural components of a rotor blade?

What are the internal structural components of a rotor blade?

Signup and view all the flashcards

What is bonding in rotor blade construction?

What is bonding in rotor blade construction?

Signup and view all the flashcards

What is a disadvantage of the single-pocket rotor blade?

What is a disadvantage of the single-pocket rotor blade?

Signup and view all the flashcards

What is an advantage of the multiple-pocket rotor blade?

What is an advantage of the multiple-pocket rotor blade?

Signup and view all the flashcards

Tracking Weights

Tracking Weights

Signup and view all the flashcards

Trim Tab

Trim Tab

Signup and view all the flashcards

Rotor Blade Tracking

Rotor Blade Tracking

Signup and view all the flashcards

Bonding

Bonding

Signup and view all the flashcards

Faying surface

Faying surface

Signup and view all the flashcards

Mass balance weight

Mass balance weight

Signup and view all the flashcards

Spanwise balance

Spanwise balance

Signup and view all the flashcards

Spanwise balance weight

Spanwise balance weight

Signup and view all the flashcards

Solvent's effect on bonds

Solvent's effect on bonds

Signup and view all the flashcards

Spanwise balance weight

Spanwise balance weight

Signup and view all the flashcards

Weight movement

Weight movement

Signup and view all the flashcards

Study Notes

Rotary Wing Aerodynamics

- AVIA-1035 course

- Focuses on rotor blade aerodynamics

Rotor Blades

- Design and construction vary between manufacturers, but all aim for efficiency and cost-effectiveness.

- Helicopter design dictates specific requirements for rotor blades, influencing their design.

Rotor Blade Design

- Most blades are symmetrical airfoils to create a stable aerodynamic pitch.

- Stability is ensured when the center of gravity, center of pressure, and feathering axis are aligned.

- The constant alignment of these forces across blade pitch changes yields flight stability.

Asymmetrical Airfoils

- Asymmetrical airfoils are becoming more common

- This design is capable of producing greater lift compared to symmetrical airfoils.

- Aerodynamic stability achieved with a 3° upward angle on the trailing edge.

- This design counteracts excessive center of pressure shifts

Rotor Blade Materials

- Common materials include aluminum, steel, brass, and fiberglass.

- Initial blades often used wood, still used in some applications.

- Metal blades were used next, followed by composite designs incorporating multiple materials.

- Composite blades are the most recent design.

Wooden Rotor Blades

- First production blades employed laminated wood from various species (birch, spruce, pine, balsa).

- A steel core was placed within the wood laminations near the leading edge for reinforcement.

- A resin-impregnated fiberglass cloth covers the exterior surfaces.

Wooden Blade Details

- Two-thirds of the outboard leading edge covered with stainless steel caps for abrasion prevention.

- Blade pairs are often a matching set for construction consistency; a single blade is not easily substituted.

- Moisture affects wood blades; this can be mitigated by a brief helicopter run-up.

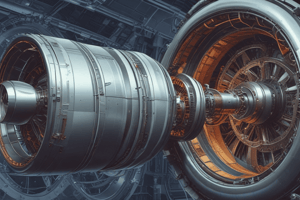

Metal Rotor Blades (Aluminum)

- Have been used for over 40 years.

- Construction varies considerably among manufacturers and over time.

- Typical blades use an extruded hollow aluminum spar forming the leading edge.

- Quality control during construction is an advantage.

Metal Blades - Design Details

- Single blades can be replaced without a matched set.

- Aluminum pockets bonded to the trailing edge help with streamlining.

- An aluminum tip cap is fastened using screws, enhancing assembly efficiency.

- Metal blades have a limited lifespan due to flight stresses.

Rotor Blades - Diagrams

- Diagrams (Figures 3-6, 3-7, 3-8, 3-9, 3-10, 3-11, 3-12, 3-13, 3-14, 3-15, 3-16, 3-17. 3-18, 3-19, 3-20, 3-21, 3-22, 3-23, and 3-24) depict blade components and construction features.

Fiberglass/Composite Rotor Blades

- Fiberglass is a primary material for construction.

- The spar can be made of fiberglass or metal.

- Roving material impregnated with epoxy resin is wound around a foam core.

- Fiberglass cloth makes up the blade skins, providing rigidity and protection.

Rotor/Blade Reinforcement/Additions

- Root reinforcement plates are added to fiberglass blades.

- Trail edge foam filler and additional roving strips to the trailing edge reinforce stability.

- Fiber coverings that add fairing and streamline the blade.

- The leading edge of the fiberglass blade is protected by a stainless steel strip.

- Balancing weights are added to the blade tip during manufacturing.

Rotor Blade - Aluminum Hollow Spar Design

- Featured in Figure 3-7, highlighting structural details.

Rotor Blade - Composite Roving Design

- Depicted in Figure 3-7, showing the blade root details.

Rotor Blade - Other Details

- Additional protection with rubber erosion strips bonded to the underside of the blade.

- Steel socket for attaching the blade to the rotor head.

- Stainless steel tip caps fastened to the spar and tip pocket.

- Internal grounding strips for static electricity transfer to the aircraft.

Blade Nomenclature

- The planform is the blade shape viewed from above.

- Uniform planforms are common for easier construction.

- Tapered planforms give better lift throughout the blade.

Rotor Blade - Span and Span Line

- Span is the distance from root to tip, a crucial measurement.

- Span line is an imaginary line that runs parallel to the blade from the root to the tip.

- Damages are often reported relative to the location on the span line.

Rotor Blade Defects

- Defects parallel to the span line are less critical; the chordwise stress affects the entire blade.

Chord and Chord Line

- Blade width measured at the widest point, the chord.

- Chord line an imaginary line from leading to trailing edge, perpendicular to the span line.

- Used as a reference line for angular measurement.

Spar Construction

- Spar, the primary support structure, is often made of aluminum, steel or fiberglass.

- Usually D-shaped, forming the airfoil leading edge.

- Shape varies based on material and blade design fit.

Blade Construction - Other Components

- Internal structural components include ribs, I-beams, spanwise channels, and aluminum honeycomb foil for strength.

Bonding

- Bonding methods reduce hardware needs, which usually weaken the structural bond.

- Bonding surfaces called faying surfaces.

- This process is not susceptible to chemical damage or many cleaning solvents.

Blade Construction - Single Pocket

- Uses a single, continuous skin for top and bottom construction

- Skin wraps across the entire span and chord from behind the spar.

- Simple design minimizes the number of joining points (pockets) or fairings during bonding.

Blade Construction - Multiple Pocket

- Most large-rotor blades use multiple pockets or fairings behind the spar

- Repairs only require replacing pockets or fairings instead of the entire blade, making repairs more efficient and cost-effective.

Blade Balance

- Three types of balancing weights (mass chordwise, spanwise, and tracking) are used to ensure proper balance and distribution.

- Mass balance bars are bonded to the leading edge of the blade.

- Balance ensures that the center of gravity is about 25% of the chord.

- Manufacturer-specific methods, shapes, and locations for balance vary.

Blade Movement Restriction

- Usually, helicopter blade weights are fixed and not easily repositioned or adjusted.

- Changing weights affect the center of gravity.

- Spanwise weights affect the center of gravity to move outward or inward.

Blade Construction & Efficiency

- Rotating blades should track on the same level plane for efficiency and vibration-free operation.

- Tracking deviations cause vibrations leading to damage and reduced comfort.

- Air turbulence caused by blade rotation also reduces performance.

Blade Construction - Trim Tabs

- Trim tabs are used to fine-tune the blade's position in the plane of rotation.

- Placement is typically at the blade tip for the necessary aerodynamic reaction.

Tail Rotor Blades

- Tail rotor blades are used for directional control in helicopters.

- Metal blades are built similarly to the main rotor blades with aluminum extrusions, hollow extrusions, and sheet channels.

- Fiberglass tail rotor blades use fiberglass sheets and solid titanium spars.

Blade Preservation and Storage

- Maintenance instructions for rotor blade handling, storage, inspections, and documentation.

- Condemn blades with nonrepairable damage.

- Tape blade holes and inspect for damage.

- Clean the blade external surfaces.

- Protect surface areas from erosion or corrosion.

- Secure blades and containers after cleaning and repairs.

- Document critical information such as NSN, model, and serial number.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.