Podcast

Questions and Answers

What is the purpose of the diffuser in a gas turbine engine?

What is the purpose of the diffuser in a gas turbine engine?

- To reduce the air velocity before it enters the combustion chamber. (correct)

- To mix the air with fuel before it enters the combustion chamber.

- To increase the static pressure before it enters the combustion chamber.

- To increase the air velocity before it enters the combustion chamber.

What determines the Angle of Attack (AOA) of the compressor blade?

What determines the Angle of Attack (AOA) of the compressor blade?

- Static pressure and air density.

- Inlet air velocity and compressor rpm. (correct)

- Compressor surge and aerofoil design.

- Fuel control sensors and compressor stall.

What happens when a single compressor blade or stage stalls?

What happens when a single compressor blade or stage stalls?

- It is said to have stalled. (correct)

- The entire compressor stalls.

- The engine shuts down.

- The engine experiences a surge.

What is the result of a compressor stall?

What is the result of a compressor stall?

What can cause engine damage and a loud audible noise?

What can cause engine damage and a loud audible noise?

How can inlet designs reduce the chance of an intake-induced stall?

How can inlet designs reduce the chance of an intake-induced stall?

What is the primary task of an axial compressor?

What is the primary task of an axial compressor?

What is the result of the airflow as it passes through the rotor blades and stator vanes?

What is the result of the airflow as it passes through the rotor blades and stator vanes?

Why does the space between the rotor shaft and the stator casing gradually decrease from front to rear in an axial flow compressor?

Why does the space between the rotor shaft and the stator casing gradually decrease from front to rear in an axial flow compressor?

What is the advantage of higher compressor pressure ratios in a gas turbine engine?

What is the advantage of higher compressor pressure ratios in a gas turbine engine?

What is the compressor pressure ratio of a single stage in an axial flow compressor?

What is the compressor pressure ratio of a single stage in an axial flow compressor?

Why are multiple compressor stages needed in an axial flow compressor?

Why are multiple compressor stages needed in an axial flow compressor?

What is the primary function of the stator vanes in a compressor stage?

What is the primary function of the stator vanes in a compressor stage?

What determines the velocity present in each stage of the compressor?

What determines the velocity present in each stage of the compressor?

What is the typical material used to make rotor blades?

What is the typical material used to make rotor blades?

What is the purpose of the rotor blades in a compressor stage?

What is the purpose of the rotor blades in a compressor stage?

What is a blisk in a compressor rotor?

What is a blisk in a compressor rotor?

What is the trend in modern turbine engine design regarding blisks?

What is the trend in modern turbine engine design regarding blisks?

What is the purpose of the band in a gas turbine engine?

What is the purpose of the band in a gas turbine engine?

When are internal VBVs fully open?

When are internal VBVs fully open?

What is the purpose of the variable vane system in a gas turbine engine?

What is the purpose of the variable vane system in a gas turbine engine?

What controls the operation of the variable vane system?

What controls the operation of the variable vane system?

What happens to the variable stator vanes as the compressor speed is reduced?

What happens to the variable stator vanes as the compressor speed is reduced?

What is the benefit of the variable vane system in a gas turbine engine?

What is the benefit of the variable vane system in a gas turbine engine?

What is the primary advantage of fan blades without stabilizing support shrouds?

What is the primary advantage of fan blades without stabilizing support shrouds?

What material is commonly used for the leading edge sheath of fan blades?

What material is commonly used for the leading edge sheath of fan blades?

What is the purpose of moment weighing of fan blades?

What is the purpose of moment weighing of fan blades?

What type of fan blades are becoming the top choice for new high/ultra-high bypass engines?

What type of fan blades are becoming the top choice for new high/ultra-high bypass engines?

What is the unit of measurement for the moment weight of a fan blade?

What is the unit of measurement for the moment weight of a fan blade?

What is the benefit of integrating a computer with the mechanical system of blade moment weighing?

What is the benefit of integrating a computer with the mechanical system of blade moment weighing?

Flashcards are hidden until you start studying

Study Notes

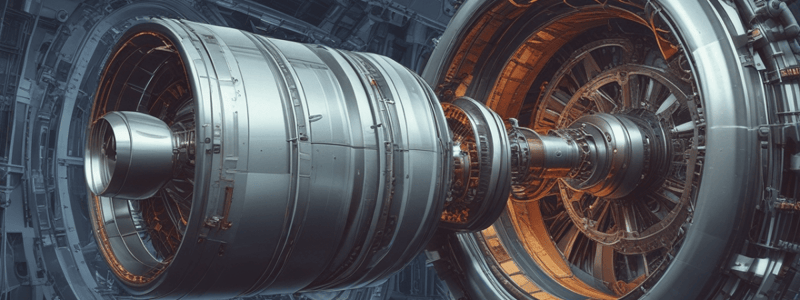

Compressor Stages

- Each rotor consists of a set of blades fitted into a disc, which moves air rearwards through each stage.

- The speed of the rotor determines the velocity present in each stage, and with increased velocity, kinetic energy is transferred to the air.

- Stator vanes are placed to the rear of the rotor blades to receive the air at high velocity and act as a diffuser, changing kinetic energy to potential energy (pressure).

Rotor Blades

- Rotor blades are aerofoils fitted into the disc and move air rearwards through each stage.

- Rotor rpm determines airflow axial velocity through each stage.

- Blades are normally made from stainless steel alloy or titanium alloy.

- Discs are made from nickel steel alloy or titanium alloy.

Blisks

- Some compressor rotors have one-piece blade and rotor units called blisks.

- Blisks are commonly used in small turboprop and turboshaft engines.

- Forged blisk technology is being applied to many smaller fans, compressor rotors, and stators, and to some turbine components.

Axial Flow Compressor Operation

- A single stage in an axial flow compressor can produce a compressor pressure ratio of approximately 1.25:1.

- High compressor pressure ratios are obtained by adding more compressor stages.

- The task of an axial compressor is to raise air pressure rather than air velocity.

- Each compressor stage raises the pressure of the incoming air while the air's velocity is alternately increased, then decreased as airflow proceeds through the compressor.

Compressor Pressure Ratio

- The compressor pressure ratio of a gas turbine engine is an extremely important design consideration.

- The higher the compression, the more remarkable the advantage to the operating cycle in terms of thermal efficiency.

- The diffuser is known as the point of highest pressure in the gas turbine engine.

Compressor Stall and Surge

- Compressor aerofoils experience an infinite variety of AOAs and air densities, and controlling the angle of attack (AOA) is a design function.

- Compressor stall is an imbalance between the two vector quantities of inlet air velocity and compressor rpm.

- When a single compressor blade or stage stalls, it is said to have stalled. When the entire compressor stalls, it is known as surge.

Fan Blade Design

- The latest high-bypass engines have low-aspect-ratio fan blades, known as wide chord blades.

- Swept fan blades are now becoming the top choice for all new high/ultra-high bypass engines among leading manufacturers.

- Low-aspect-ratio fan blades, without mid-span shrouds, produce a higher mass airflow.

Fan Blade Replacement

- With the introduction of the large fan blade, moment weighing of blades has assumed a greater significance.

- The moment weight of a blade is identical to the unbalance effect of the blade when installed into a disc.

- The recorded measurement of blade moment weights enables each blade to be distributed around the disc so that these unbalances are cancelled.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.