Podcast

Questions and Answers

What is the function of pneumatic system devices?

What is the function of pneumatic system devices?

To convert compressed air energy into mechanical energy

What is a Single Acting Cylinder used for?

What is a Single Acting Cylinder used for?

For tasks that do not require a significant amount of force

What are the typical size limits for commonly produced single-acting cylinders?

What are the typical size limits for commonly produced single-acting cylinders?

Up to 100 mm in diameter and a stroke of up to 100 mm

Which of the following is a component of a single-acting cylinder?

Which of the following is a component of a single-acting cylinder?

What is the function of a double acting cylinder?

What is the function of a double acting cylinder?

What is the primary characteristic of a double-acting cylinder without cushioning?

What is the primary characteristic of a double-acting cylinder without cushioning?

What is the purpose of using air as a cushion in double-acting cylinders?

What is the purpose of using air as a cushion in double-acting cylinders?

Describe a double end rod cylinder.

Describe a double end rod cylinder.

What is the range of motion for the piston rod in a rotary actuator?

What is the range of motion for the piston rod in a rotary actuator?

What is an air motor typically used for?

What is an air motor typically used for?

How do grippers function?

How do grippers function?

What are vacuum generators used for?

What are vacuum generators used for?

Flashcards

Pneumatic Actuators

Pneumatic Actuators

Devices that operate using compressed air to convert pneumatic energy into mechanical work.

Single Acting Cylinder

Single Acting Cylinder

A cylinder where the air pressure acts in only one direction, and a spring returns it to its original position.

Double Acting Cylinder

Double Acting Cylinder

A Cylinder where air pressure can be applied in both directions to extend and retract the piston rod.

Cylinder Without Cushioning

Cylinder Without Cushioning

Signup and view all the flashcards

Cylinder with Air Cushion

Cylinder with Air Cushion

Signup and view all the flashcards

Double End Rod Cylinder

Double End Rod Cylinder

Signup and view all the flashcards

Rotary Actuator

Rotary Actuator

Signup and view all the flashcards

Air Motor

Air Motor

Signup and view all the flashcards

Grippers

Grippers

Signup and view all the flashcards

Grippers - Finger Separating

Grippers - Finger Separating

Signup and view all the flashcards

Parallel Grippers

Parallel Grippers

Signup and view all the flashcards

Vacuum Generators

Vacuum Generators

Signup and view all the flashcards

Piston

Piston

Signup and view all the flashcards

Piston Rod

Piston Rod

Signup and view all the flashcards

Return Spring

Return Spring

Signup and view all the flashcards

Base End Cover

Base End Cover

Signup and view all the flashcards

Head End Cover

Head End Cover

Signup and view all the flashcards

Cylinder Tube

Cylinder Tube

Signup and view all the flashcards

Pressure Connection

Pressure Connection

Signup and view all the flashcards

Vent Hole

Vent Hole

Signup and view all the flashcards

Study Notes

- Pneumatic system devices function to convert compressed air energy into mechanical work.

Single Acting Cylinder

- Single acting cylinders are suitable for applications requiring less force.

- The acting force is countered by a spring.

- Commonly produced with a bore size of no more than 100 mm and a stroke of no more than 100 mm.

Single Acting Cylinder Components

- Piston

- Piston rod

- Return spring

- Base end cover

- Head end cover

- Cylinder tube

- Pressure connection

- Vent hole

- Bash and sealing element

- Piston seal

Double Acting Cylinder

- Double acting cylinders.

Double Acting Cylinder Components

- Seal and piston

- Cylinder tube

- Air seal

- Piston rod

Double Acting Cylinder (No Cushioning)

- Double acting cylinders without cushioning use air pressure for movement in both directions.

- Affordable option suitable for low-speed applications.

Double Acting Cylinder (Cushioning)

- Double acting cylinders with cushioning are designed for higher speed operations.

- Movement relies on air pressure.

- Air cushioning is used to prevent impact between the piston and end caps at the end of the stroke.

Double End Rod Cylinder

- Double end rod cylinders share a similar structure to single acting cylinders but feature two piston rods.

- Both rods extend from either side and move in alternating directions.

Rotary Actuators

- Rotary actuators feature rods that rotate back and forth but are limited to a maximum rotation of 360°.

- Rotation can be controlled clockwise or counterclockwise.

- Applications require specification of the actuator's rotation angle

Air Motor

- Air motors are used in high-impact applications or those needing air pressure to impact a workpiece beyond normal tasks, such as drilling.

- Can rotate 360 degrees.

Grippers

- Grippers employ mechanical mechanisms to work in conjunction with cylinders to grip materials or workpieces of various shapes.

- Includes finger separation.

Grippers (Parallel End Type)

- Grippers with parallel fingers.

Vacuum Generators

- Vacuum generators are used for vacuuming and gripping objects.

- Operation is dependent on the design of the rubber cup.

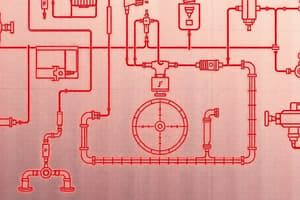

Pneumatic Symbols

- Several Pneumatic symbols that represent

- Single acting cylinder with air pressure

- Spring return

- Double ended piston, double acting cylinder

- Single cylinder with spring return etc

- Motor symbols represented include

- Single driven with adjustable pressure

- Double drive motor with adjustable pressure

- Rotate Cylinder

- The document features symbols for work pieces as well

- Two way operated

- Single way operated

- Parallel movement

- NC/NO push types

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.