Podcast

Questions and Answers

What is the primary function of pneumatic controllers?

What is the primary function of pneumatic controllers?

- To amplify electrical signals

- To regulate fluid flow

- To measure temperature

- To convert electrical energy to pneumatic energy (correct)

What is a common issue in pneumatic relays that requires repair?

What is a common issue in pneumatic relays that requires repair?

- Overheating of the relay coil

- Leaks in the hydraulic system

- Blockages in air lines (correct)

- Corrosion of electrical contacts

What tool is typically used to diagnose issues in pneumatic controllers?

What tool is typically used to diagnose issues in pneumatic controllers?

- Pneumatic pressure gauge (correct)

- Multimeter

- Oscilloscope

- Thermocouple

What is a benefit of regular maintenance in pneumatic controllers and relays?

What is a benefit of regular maintenance in pneumatic controllers and relays?

What skill is essential for repairing pneumatic controllers and relays?

What skill is essential for repairing pneumatic controllers and relays?

What is a typical sign that a pneumatic controller may need repair?

What is a typical sign that a pneumatic controller may need repair?

Which component is critical to ensure proper functioning of pneumatic relays?

Which component is critical to ensure proper functioning of pneumatic relays?

What might be a consequence of neglecting regular repair on pneumatic controllers?

What might be a consequence of neglecting regular repair on pneumatic controllers?

What is an important aspect of diagnosing issues in pneumatic controllers?

What is an important aspect of diagnosing issues in pneumatic controllers?

Which replacement part is commonly needed during the repair of pneumatic relays?

Which replacement part is commonly needed during the repair of pneumatic relays?

What is the primary goal of repairing pneumatic controllers and relays?

What is the primary goal of repairing pneumatic controllers and relays?

Why is it essential to perform regular maintenance on pneumatic controllers and relays?

Why is it essential to perform regular maintenance on pneumatic controllers and relays?

What is a common symptom of a faulty pneumatic controller?

What is a common symptom of a faulty pneumatic controller?

Who typically performs repairs on pneumatic controllers and relays?

Who typically performs repairs on pneumatic controllers and relays?

What is a critical step in the repair process of pneumatic controllers and relays?

What is a critical step in the repair process of pneumatic controllers and relays?

What is the primary reason for performing regular maintenance on pneumatic controllers and relays?

What is the primary reason for performing regular maintenance on pneumatic controllers and relays?

What is a critical aspect of repairing pneumatic controllers and relays?

What is a critical aspect of repairing pneumatic controllers and relays?

What is a common consequence of neglecting regular repair of pneumatic controllers and relays?

What is a common consequence of neglecting regular repair of pneumatic controllers and relays?

What is an essential skill for technicians repairing pneumatic controllers and relays?

What is an essential skill for technicians repairing pneumatic controllers and relays?

What is a typical goal of repairing pneumatic controllers and relays?

What is a typical goal of repairing pneumatic controllers and relays?

Flashcards are hidden until you start studying

Study Notes

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers and relays are critical components in automated systems, utilizing compressed air for operation.

- Regular maintenance and repair extend the lifespan and ensure the efficiency of these devices.

- Common issues include air leaks, mechanical failures, and calibration errors, which can impede performance.

- Troubleshooting involves identifying the source of malfunctions through systematic testing and inspection.

- Replacement of worn-out components, such as diaphragms and seals, is often necessary for restoring function.

- Proper lubricants and cleaning agents are essential for maintaining the operational integrity of pneumatic systems.

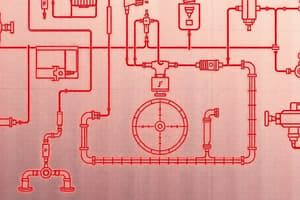

- Familiarization with schematics and manuals is crucial for effective repairs and understanding component functions.

- Safety procedures must always be followed, including depressurizing systems before conducting repairs to prevent accidents.

Objective for Repair

- Understanding the principles behind pneumatic controllers and relays is essential for effective repair and maintenance.

- Pneumatic controllers are devices that use air pressure to regulate various processes in industrial settings.

- Relays are electromagnetic switches used to control the flow of electricity in conjunction with pneumatic systems.

Key Repair Techniques

- Regular inspection of pneumatic components can identify wear and potential failure points, ensuring proactive maintenance.

- Utilize appropriate tools and safety equipment when conducting repairs to minimize risks.

- Common issues include leaks in air supply, malfunctioning valves, and inconsistent pressure regulation.

Components of Pneumatic Systems

- Pneumatic controllers typically consist of sensors, actuators, and control valves which work together to manage air pressure levels.

- Relays function as intermediaries to operate larger devices using smaller electrical signals, ensuring reliability in control systems.

Maintenance Best Practices

- Schedule routine maintenance checks to prolong the life of pneumatic controllers and relays.

- Keep detailed logs of performance and repairs to track operational efficiency and identify recurring problems.

- Ensure all repairs adhere to manufacturer specifications to maintain warranty coverage and system integrity.

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers and relays are critical components in industrial automation systems.

- They regulate pressure, flow, and temperature using compressed air as a control medium.

- Regular maintenance and timely repairs ensure operational efficiency and prolong equipment lifespan.

- Common failure points include leaks in hoses, worn-out seals, and malfunctioning valves.

- Diagnosing issues requires understanding pneumatic diagrams and using pressure gauges.

- Repair processes may involve replacing damaged components and calibrating settings for optimal performance.

- Knowledge of safety protocols is essential, especially when dealing with pressurized systems.

- Training in troubleshooting techniques can enhance problem-solving skills in maintenance scenarios.

- Familiarity with manufacturers’ manuals is crucial for correct parts identification and repair procedures.

- Proper documentation of maintenance activities supports regulatory compliance and future repairs.

Repair of Pneumatic Controllers and Relays

- Pneumatic controllers and relays are essential in automated systems for regulating processes.

- They operate by using compressed air to control valve positions and other mechanisms in industrial applications.

- Regular maintenance and repair of these components are critical for ensuring operational efficiency and reliability.

- Common issues include leaks, wear and tear of seals, and malfunctioning sensors.

- Effective troubleshooting involves checking air supply pressure, inspecting components for damage, and ensuring proper calibration.

- Replacement of defective parts should follow manufacturer specifications to maintain system integrity.

- Safety precautions must be observed when working on pneumatic systems to prevent accidents and ensure proper functioning.

- Understanding the operational principles of pneumatic systems aids in diagnosing problems effectively.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.