Podcast

Questions and Answers

How is non-woven fabric created?

How is non-woven fabric created?

- By bonding fibers together using various methods (correct)

- By weaving threads together

- By knitting threads together

- By spinning fibers into a yarn

What is the purpose of spunbonding in creating non-woven fabric?

What is the purpose of spunbonding in creating non-woven fabric?

- To form fibers into a web

- To bond fibers together by melting and cooling them (correct)

- To create a melt-blown mat

- To blow fine fibers through an extruder

What is one of the key characteristics of polyester fibers used in non-woven materials?

What is one of the key characteristics of polyester fibers used in non-woven materials?

- Heavyweight

- Non-biodegradable

- Low absorbency

- High-strength (correct)

Which industry uses non-woven materials for sound insulation and filtration purposes?

Which industry uses non-woven materials for sound insulation and filtration purposes?

Which method involves blowing fine fibers through an extruder and then cooling them in the air to create non-woven fabric?

Which method involves blowing fine fibers through an extruder and then cooling them in the air to create non-woven fabric?

Which of the following materials is commonly used in non-woven fabrics due to its low cost and good mechanical properties?

Which of the following materials is commonly used in non-woven fabrics due to its low cost and good mechanical properties?

What is a current focus area in research to improve non-woven materials?

What is a current focus area in research to improve non-woven materials?

Which of the following is NOT mentioned as an application area for non-woven materials?

Which of the following is NOT mentioned as an application area for non-woven materials?

What do researchers aim to achieve by incorporating nanoparticles into non-woven materials?

What do researchers aim to achieve by incorporating nanoparticles into non-woven materials?

What is the key feature of polypropylene (PP) that makes it suitable for use in non-woven materials?

What is the key feature of polypropylene (PP) that makes it suitable for use in non-woven materials?

What type of fabrics are created through various bonding techniques using a range of materials?

What type of fabrics are created through various bonding techniques using a range of materials?

Which process involves a combination of melt blowing and spunbonding to create a final non-woven fabric?

Which process involves a combination of melt blowing and spunbonding to create a final non-woven fabric?

Flashcards are hidden until you start studying

Study Notes

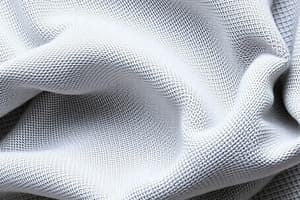

Non-Woven Manufacturing Process

Non-woven fabric is a unique material that is not woven or knitted from threads. Instead, it is created by bonding together fibers using various methods. This article will discuss the manufacturing process of non-woven materials, focusing on the techniques used and the materials involved.

Bonding Techniques

There are three primary methods for bonding fibers together to create non-woven fabrics:

-

Melt Blowing: This process involves blowing fine fibers through an extruder and then cooling them in the air. The fibers are bonded together by the heat of the air, forming a non-woven mat.

-

Spunbonding: In this method, fibers are formed into a web and then bonded together by melting and cooling them. This process can be used to create both thin, lightweight materials and thicker, more durable fabrics.

-

Melt-blown-spunbonding: This is a combination of melt blowing and spunbonding. Fibers are first melt-blown to create a melt-blown mat, which is then spunbonded to create a final non-woven fabric.

Materials

Non-woven fabrics can be made from a variety of materials, including:

-

Polypropylene (PP): PP is a thermoplastic polymer that is commonly used in non-woven materials due to its high strength, low density, and excellent heat resistance.

-

Polyethylene (PE): Similar to PP, PE is a thermoplastic polymer that is widely used in non-woven materials due to its low cost and good mechanical properties.

-

Polyester: Polyester fibers can be used in non-woven materials to create high-strength, lightweight fabrics.

Applications

Non-woven materials have a wide range of applications, including:

-

Medical and hygiene products: Non-woven fabrics are used in items such as disposable diapers, surgical gowns, and masks due to their high strength and absorbency.

-

Food packaging: Non-woven materials can be used to create biodegradable and compostable packaging for food products.

-

Automotive: Non-woven materials are used in the automotive industry for applications such as sound insulation and filtration.

-

Geotextiles: Non-woven fabrics are used in the construction industry for erosion control, drainage, and filtration.

Future Developments

Research is ongoing to improve the sustainability and functionality of non-woven materials. Some areas of focus include:

-

Bio-based materials: Developing non-woven fabrics from renewable resources such as cellulose and lignocellulose.

-

Nano-composites: Incorporating nanoparticles into non-woven materials to enhance their mechanical properties and barrier performance.

-

Smart materials: Developing non-woven fabrics with embedded sensors or other functionalities to create "smart" materials.

In conclusion, non-woven materials are created through various bonding techniques using a range of materials. These fabrics have a wide range of applications, and research is ongoing to improve their sustainability and functionality.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.