Podcast

Questions and Answers

What primarily determines a metal's suitability for welding in terms of its reactivity?

What primarily determines a metal's suitability for welding in terms of its reactivity?

- Its density and weight

- Its color and luster

- Its tendency to react with gases, acids, or bases (correct)

- Its melting point

Metals that are highly reactive are generally more suitable for welding without any special precautions.

Metals that are highly reactive are generally more suitable for welding without any special precautions.

False (B)

Name one factor that increases metal reactivity based on periodic table trends.

Name one factor that increases metal reactivity based on periodic table trends.

Moving down a group

The use of __________ gases is vital in MIG welding to prevent oxygen from compromising weld quality.

The use of __________ gases is vital in MIG welding to prevent oxygen from compromising weld quality.

Match the metal to its reactivity level:

Match the metal to its reactivity level:

Why is sodium not used in welding?

Why is sodium not used in welding?

Noble metals, such as gold, are highly reactive due to their unstable electron configurations.

Noble metals, such as gold, are highly reactive due to their unstable electron configurations.

What measures might welders take to ensure strong welds in reactive metals?

What measures might welders take to ensure strong welds in reactive metals?

__________ is a chemical reaction where metals react with oxygen, forming oxides.

__________ is a chemical reaction where metals react with oxygen, forming oxides.

Match the term with its correct description:

Match the term with its correct description:

Which outcome is most likely if highly reactive metals are welded without protection?

Which outcome is most likely if highly reactive metals are welded without protection?

Cleaning metal surfaces is unnecessary when welding reactive metals if proper shielding gases are used.

Cleaning metal surfaces is unnecessary when welding reactive metals if proper shielding gases are used.

Why is it important to understand oxidation and corrosion in agricultural mechanics?

Why is it important to understand oxidation and corrosion in agricultural mechanics?

Rusting is a common effect of __________ particularly in iron and its alloys.

Rusting is a common effect of __________ particularly in iron and its alloys.

Match the welding issue with the appropriate preventive measure:

Match the welding issue with the appropriate preventive measure:

Which of the following metals is known for its low reactivity?

Which of the following metals is known for its low reactivity?

Reactive metals are suitable for applications needing long-term stability without protective measures.

Reactive metals are suitable for applications needing long-term stability without protective measures.

In what applications are stable metals like gold often utilized?

In what applications are stable metals like gold often utilized?

When welding reactive metals, __________ coatings and shielding gases are necessary to prevent oxidation.

When welding reactive metals, __________ coatings and shielding gases are necessary to prevent oxidation.

Match the metal handling requirement with reactive or stable classification:

Match the metal handling requirement with reactive or stable classification:

For what purpose is platinum primarily utilized in applications?

For what purpose is platinum primarily utilized in applications?

Oxidation can improve the structural integrity of metals over time.

Oxidation can improve the structural integrity of metals over time.

Name one shielding gas used to prevent the intrusion of oxygen during welding.

Name one shielding gas used to prevent the intrusion of oxygen during welding.

In the periodic table, metal reactivity __________ as you move down the group and to the left.

In the periodic table, metal reactivity __________ as you move down the group and to the left.

Match the metal with the characteristic it's known for

Match the metal with the characteristic it's known for

Flashcards

Definition of reactivity?

Definition of reactivity?

Reactivity refers to how easily an element reacts with other substances like gases, acids, or bases.

Periodic table reactivity trends?

Periodic table reactivity trends?

Metal reactivity increases as you move down the group and to the left on the periodic table.

Example of a reactive metal?

Example of a reactive metal?

Sodium exemplifies a highly reactive metal, reacting violently with water and oxygen.

Characteristics of stable metals?

Characteristics of stable metals?

Signup and view all the flashcards

Characteristics of reactive metals?

Characteristics of reactive metals?

Signup and view all the flashcards

Handling reactive metals in welding?

Handling reactive metals in welding?

Signup and view all the flashcards

Impact on weld quality?

Impact on weld quality?

Signup and view all the flashcards

Role of shielding gas?

Role of shielding gas?

Signup and view all the flashcards

Protecting the weld pool?

Protecting the weld pool?

Signup and view all the flashcards

Definition of oxidation?

Definition of oxidation?

Signup and view all the flashcards

Effects of oxidation rusting?

Effects of oxidation rusting?

Signup and view all the flashcards

Prevention methods for welders?

Prevention methods for welders?

Signup and view all the flashcards

Study Notes

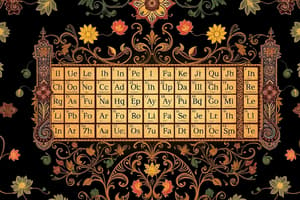

Reactivity of Metals

- Reactivity refers to how easily an element reacts with other substances such as gases, acids, or bases.

- Highly reactive metals often undergo chemical changes readily.

- In the periodic table, metal reactivity increases as you move down the group and to the left.

- Cesium and Francium are among the most reactive.

- Noble metals like gold are less reactive due to their stable electron configurations.

- Sodium exemplifies a highly reactive metal, reacting violently with water and oxygen.

- Sodium's high reactivity prevents its use in welding as it can compromise weld integrity if not handled properly or kept away from contact with air.

Stable vs. Reactive Metals

- Stable metals exhibit low reactivity, making them resistant to oxidation and corrosion.

- The durability of stable metals ensures they maintain structural integrity in various applications, particularly in electronics and precision tools.

- Reactive metals tend to corrode rapidly when exposed to moisture and oxygen.

- Reactive metals are less ideal for applications requiring long-term stability without protective measures.

- When welding reactive metals like magnesium and aluminum, proper handling is necessary to prevent oxidation.

- Proper handling includes using protective coatings and shielding gases.

- Gold is widely used in electronics due to its conductivity and resistance to tarnishing.

- Platinum, is utilized in chemical reactions and high-precision instruments.

Importance of reactivity in welding

- Highly reactive metals can lead to weak welds if exposed to oxygen or moisture during welding.

- Shielding gases like argon or CO₂ are vital in MIG welding as they prevent the intrusion of oxygen that can compromise weld quality.

- Proper use of shielding gases enhances the performance and reliability of welds involving reactive metals.

- Protecting the weld pool from oxidation is essential to ensure strong welds in reactive metals.

- Cleaning metal surfaces and maintaining controlled environments are effective measures to prevent contamination during welding.

Oxidation and Corrosion

- Oxidation is a chemical reaction where metals react with oxygen, forming oxides.

- Oxidation can compromise the metal's integrity and lead to structural failure if not managed accordingly.

- Rusting is the most common effect of oxidation, particularly in iron and its alloys.

- Rust leads to weak, flaky materials that lose strength and can no longer perform their intended function effectively.

- Techniques such as cleaning the metal surfaces and employing shielding gases like argon or CO₂ are essential to prevent oxidation during welding.

- Understanding oxidation and corrosion is crucial in agricultural mechanics, where equipment may be exposed to moisture and chemicals.

- Appropriate materials and preventive measures enhance safety and longevity in components like fuel tanks and wiring.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.