Podcast

Questions and Answers

Which of the following processes is NOT typically associated with plastic deformation of metal?

Which of the following processes is NOT typically associated with plastic deformation of metal?

- Forging

- Extrusion

- Casting (correct)

- Rolling

Higher temperatures generally increase the yield strength of metals during forming processes.

Higher temperatures generally increase the yield strength of metals during forming processes.

False (B)

What type of stresses are primarily applied in the bulk deformation processes?

What type of stresses are primarily applied in the bulk deformation processes?

Compressive stresses

In metal forming, high __________ is a desirable property that allows for easier shaping of the material.

In metal forming, high __________ is a desirable property that allows for easier shaping of the material.

Match the following metal forming processes with their description:

Match the following metal forming processes with their description:

What is the main purpose of the bending process in sheet metalworking?

What is the main purpose of the bending process in sheet metalworking?

Hot rolling involves processing metals at room temperature.

Hot rolling involves processing metals at room temperature.

What are extrudates?

What are extrudates?

In metal drawing, the metal is __________ through a die.

In metal drawing, the metal is __________ through a die.

Match the following processes with their descriptions:

Match the following processes with their descriptions:

Which of the following operations is often referred to as pressworking?

Which of the following operations is often referred to as pressworking?

Cold rolling can be performed at temperatures above 900°C.

Cold rolling can be performed at temperatures above 900°C.

What tooling is typically used in cutting operations in sheet metalworking?

What tooling is typically used in cutting operations in sheet metalworking?

What is the recrystallization temperature in terms of the melting point on an absolute scale?

What is the recrystallization temperature in terms of the melting point on an absolute scale?

Hot working generally results in work hardening of metals.

Hot working generally results in work hardening of metals.

What happens to the yield strength and ductility of low carbon steel as cold work is increased?

What happens to the yield strength and ductility of low carbon steel as cold work is increased?

Hot working is typically performed somewhat above __________ of the melting point.

Hot working is typically performed somewhat above __________ of the melting point.

Match the following characteristics with either hot working or cold working:

Match the following characteristics with either hot working or cold working:

What is one advantage of cold working?

What is one advantage of cold working?

Warm working is performed at temperatures above the recrystallization temperature.

Warm working is performed at temperatures above the recrystallization temperature.

What is the term used to describe the process that requires the metal to be heated to allow further deformation in cold working?

What is the term used to describe the process that requires the metal to be heated to allow further deformation in cold working?

In warm working, the dividing line between cold working and warm working is often expressed in terms of _________ temperature.

In warm working, the dividing line between cold working and warm working is often expressed in terms of _________ temperature.

Match the following types of metal working with their primary characteristics:

Match the following types of metal working with their primary characteristics:

Which of the following is a disadvantage of cold working?

Which of the following is a disadvantage of cold working?

One disadvantage of warm working is the scaling of part surfaces.

One disadvantage of warm working is the scaling of part surfaces.

What is a key advantage of warm working compared to cold working?

What is a key advantage of warm working compared to cold working?

Flashcards

Metal Forming

Metal Forming

Changing a metal's shape using plastic deformation.

Plastic Deformation

Plastic Deformation

Permanent shape change in a material without breaking.

Material Properties (Metal Forming)

Material Properties (Metal Forming)

Low yield strength and high ductility are ideal for metal forming.

Bulk Deformation

Bulk Deformation

Signup and view all the flashcards

Yield Strength

Yield Strength

Signup and view all the flashcards

Forging

Forging

Signup and view all the flashcards

Cold Working

Cold Working

Signup and view all the flashcards

Warm Working

Warm Working

Signup and view all the flashcards

Hot Working

Hot Working

Signup and view all the flashcards

Recrystallization Temperature

Recrystallization Temperature

Signup and view all the flashcards

Advantages of Cold Working

Advantages of Cold Working

Signup and view all the flashcards

Disadvantages of Cold Working

Disadvantages of Cold Working

Signup and view all the flashcards

Sheet Metalworking

Sheet Metalworking

Signup and view all the flashcards

Bending (Sheet Metalworking)

Bending (Sheet Metalworking)

Signup and view all the flashcards

Deep Drawing (Sheet Metalworking)

Deep Drawing (Sheet Metalworking)

Signup and view all the flashcards

Cutting (Sheet Metalworking)

Cutting (Sheet Metalworking)

Signup and view all the flashcards

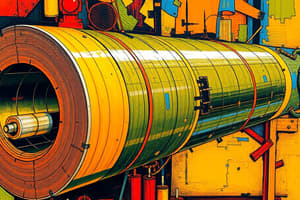

Rolling (Metal Forming)

Rolling (Metal Forming)

Signup and view all the flashcards

Metal Extrusion

Metal Extrusion

Signup and view all the flashcards

Metal Drawing

Metal Drawing

Signup and view all the flashcards

Hot working temperature

Hot working temperature

Signup and view all the flashcards

Hot working advantage: Isotropy

Hot working advantage: Isotropy

Signup and view all the flashcards

Hot working disadvantage: Oxidation

Hot working disadvantage: Oxidation

Signup and view all the flashcards

Cold working effect: Yield strength

Cold working effect: Yield strength

Signup and view all the flashcards

Cold working effect: Ductility

Cold working effect: Ductility

Signup and view all the flashcards

Study Notes

Metal Manufacturing Process

- Metal forming changes metal workpiece shapes.

- Dies apply stresses exceeding the metal's yield strength.

- Metal's shape aligns with the die's geometry.

- Plastic deformation stresses are typically compressive.

- Examples include rolling, forging, and extrusion.

- Some processes use tensile stresses (stretching) or both tensile and compressive stresses (bending), or shear stresses (shear spinning).

Material Properties in Metal Forming

- Desirable metal properties include low yield strength and high ductility.

- These properties change with temperature; ductility increases and yield strength decreases as temperature rises.

- Other factors influencing forming include strain rate and friction.

Basic Types of Deformation Processes

- Bulk deformation: Significant shape changes in large components.

- Examples: Rolling, forging, extrusion, and wire/bar drawing.

- Sheet metalworking: Forming operations on thin metal sheets (e.g., strips, coils).

- Examples: Bending, deep drawing, and cutting.

Bulk Deformation Processes

- Rolling: Thick metals are passed between rollers to reduce thickness. Types include hot (high temperature) and cold (room temperature) rolling.

- Forging: Metal is shaped by hammering or pressing.

- Extrusion: A metal billet is pushed through a die to create desired profiles ("extrudates").

- Wire and Bar Drawing: Drawing metal through dies to reduce cross-sectional area.

Metal Extrusion

- A metal forming process where a billet is forced through a die to produce specific cross-sections (extrudates).

- This is done using either mechanical or hydraulic presses.

Sheet Metalworking (cont.)

- Bending: Shaping metal sheets into desired profiles.

- Deep drawing: Forming a sheet of metal into a cavity, often resulting in hollow shapes.

- Shearing: Cutting metal sheets using specialized dies.

Metal Drawing

- A manufacturing process that reduces metal stock cross-section by forcing it through a die.

- Similar to extrusion, but drawing pulls the metal through the die opening.

Drawing Process

- Performed in cold conditions for better accuracy.

- Metal is hardened beforehand.

- Surfaces are cleaned (e.g., shot blasting).

- Metal is washed and dried.

- Lubricating chemicals are applied.

Temperature in Metal Forming

- Deformation is often more efficient at elevated temperatures.

- Metal forming temperatures are categorized into:

- Cold working (room temperature or slightly above)

- Warm working (above room temperature, but below recrystallization)

- Hot working (above recrystallization temperature).

1. Cold Working

- Performed at or slightly above room temperature.

- Many mass production operations use cold forming.

- Minimal machining is typically needed.

- Advantages include better accuracy, tolerances, and surface finish; no heating is required.

- Disadvantages include higher forces and power, strain hardening limitations.

2. Warm Working

- Performed above room temperature, but below recrystallization temperature.

- Often uses approximately 0.3 times the metal's melting point (absolute temperature).

- Advantages include lower forces and power compared to cold working; more intricate shapes are possible, and annealing may not be needed.

- Disadvantages include scaling on the workpiece's surface.

3. Hot Working

- Performed at temperatures above the recrystallization point.

- Roughly at 0.6 times the metal's melting point.

- Advantages include significantly easier shaping, lower forces and power, and the ability to form metals that would fracture in cold working.

- Disadvantages include lower dimensional accuracy, higher energy consumption, surface oxidation, and shorter tool life.

Impact of Cold Work

- Increased cold work leads to increased yield and tensile strength, and decreased ductility.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.