Podcast

Questions and Answers

What is a major reason for the growth in the medical applications of additive manufacturing?

What is a major reason for the growth in the medical applications of additive manufacturing?

- Elimination of custom devices

- Higher patient expectations (correct)

- Lower survival rates for diseases

- Decreasing technology costs

Additive manufacturing is primarily focused on mass-produced devices in the medical field.

Additive manufacturing is primarily focused on mass-produced devices in the medical field.

False (B)

Name three examples of customised devices in additive manufacturing for medical applications.

Name three examples of customised devices in additive manufacturing for medical applications.

Maxillofacial prostheses, dental aligners, artificial limbs.

Additive manufacturing can influence both customised devices and _______ devices.

Additive manufacturing can influence both customised devices and _______ devices.

Match the following customised medical devices with their descriptions:

Match the following customised medical devices with their descriptions:

What is one benefit for patients regarding localized scanning and manufacturing?

What is one benefit for patients regarding localized scanning and manufacturing?

The NHS incurs costs of over £700 million per year due to missed appointments.

The NHS incurs costs of over £700 million per year due to missed appointments.

What are some potential benefits for medical staff when it comes to localized scanning?

What are some potential benefits for medical staff when it comes to localized scanning?

Reduced manual labour leads to quicker treatment and less ________ during normal use of the product.

Reduced manual labour leads to quicker treatment and less ________ during normal use of the product.

Match the following benefits to the correct groups (Patient, Medical Staff, NHS):

Match the following benefits to the correct groups (Patient, Medical Staff, NHS):

What is a benefit of using non-contact methods for producing custom devices?

What is a benefit of using non-contact methods for producing custom devices?

Traditional methods for producing customised devices are often less accurate than modern techniques.

Traditional methods for producing customised devices are often less accurate than modern techniques.

What is the primary purpose of a burn mask?

What is the primary purpose of a burn mask?

The traditional method of construction for prosthetic legs involves producing a physical _____ of the remaining limb.

The traditional method of construction for prosthetic legs involves producing a physical _____ of the remaining limb.

Match the following benefits with their corresponding types of production methods:

Match the following benefits with their corresponding types of production methods:

Which of the following is NOT mentioned as a drawback of traditional methods?

Which of the following is NOT mentioned as a drawback of traditional methods?

Weight saving is considered a factor in improving the function of devices.

Weight saving is considered a factor in improving the function of devices.

Name one reason why traditional methods may require adjustments after fitting.

Name one reason why traditional methods may require adjustments after fitting.

What is a potential disadvantage of traditional mould-making for prosthetics?

What is a potential disadvantage of traditional mould-making for prosthetics?

Using 3D printing for prosthetic sockets eliminates all manual steps in the process.

Using 3D printing for prosthetic sockets eliminates all manual steps in the process.

List one advantage of using 3D printing to create prosthetic sockets.

List one advantage of using 3D printing to create prosthetic sockets.

The stakeholder that is primarily concerned with the management of healthcare resources is the ______.

The stakeholder that is primarily concerned with the management of healthcare resources is the ______.

Match the following stakeholders with their primary concern:

Match the following stakeholders with their primary concern:

What is one way to streamline the prosthetic fitting process?

What is one way to streamline the prosthetic fitting process?

3D printing of prosthetic sockets can potentially be more expensive than traditional methods.

3D printing of prosthetic sockets can potentially be more expensive than traditional methods.

Why is it important to consider the effects on stakeholders in the prosthetic fitting process?

Why is it important to consider the effects on stakeholders in the prosthetic fitting process?

Who is involved in the impression taking stage of the process?

Who is involved in the impression taking stage of the process?

The production of the final prosthetic includes activities like fitting and colour-matching.

The production of the final prosthetic includes activities like fitting and colour-matching.

What are the costs associated with the patient consultation stage?

What are the costs associated with the patient consultation stage?

In the impression taking stage, costs include patient travel, accommodation, staff salary, laboratory time, and _____ for materials.

In the impression taking stage, costs include patient travel, accommodation, staff salary, laboratory time, and _____ for materials.

Match each stage of the process with its associated costs:

Match each stage of the process with its associated costs:

What potential advantage does eliminating the patient visit in the impression taking stage offer?

What potential advantage does eliminating the patient visit in the impression taking stage offer?

The tooling route refers to a completely digital process without any patient involvement.

The tooling route refers to a completely digital process without any patient involvement.

Identify one area where steps of the process can be eliminated or replaced.

Identify one area where steps of the process can be eliminated or replaced.

What is a main benefit of optimizing the schedule of work in the manufacturing process?

What is a main benefit of optimizing the schedule of work in the manufacturing process?

The production of molds from patterns remains unchanged regardless of the manufacturing process.

The production of molds from patterns remains unchanged regardless of the manufacturing process.

What is one method mentioned for producing patterns in manufacturing?

What is one method mentioned for producing patterns in manufacturing?

The _______ process of manufacturing often accounts for only a small fraction of the total costs.

The _______ process of manufacturing often accounts for only a small fraction of the total costs.

Match the following Additive Manufacturing processes with their descriptions:

Match the following Additive Manufacturing processes with their descriptions:

Which of the following is a potential concern during the Fused Deposition Modelling process?

Which of the following is a potential concern during the Fused Deposition Modelling process?

The primary focus of the session is on metal AM processes.

The primary focus of the session is on metal AM processes.

What do the overall process costs of manufacturing devices include beyond the physical costs?

What do the overall process costs of manufacturing devices include beyond the physical costs?

What is a primary focus of additive manufacturing (AM) in medical applications?

What is a primary focus of additive manufacturing (AM) in medical applications?

Customised devices in medical applications can include dental aligners and artificial limbs.

Customised devices in medical applications can include dental aligners and artificial limbs.

What is one common benefit of using additive manufacturing in medical applications?

What is one common benefit of using additive manufacturing in medical applications?

The production of medical devices using additive manufacturing can lead to improved ________ for patients by creating tailored solutions.

The production of medical devices using additive manufacturing can lead to improved ________ for patients by creating tailored solutions.

Match the following medical devices with their uses:

Match the following medical devices with their uses:

What is one benefit to medical staff from localized scanning and manufacturing?

What is one benefit to medical staff from localized scanning and manufacturing?

NHS incurs expenses of over £700 million annually due to missed appointments.

NHS incurs expenses of over £700 million annually due to missed appointments.

What is a potential benefit for patients resulting from reduced manual labor in the treatment process?

What is a potential benefit for patients resulting from reduced manual labor in the treatment process?

Reduced manual labor leads to less ______ during normal use of the product.

Reduced manual labor leads to less ______ during normal use of the product.

Match the following groups with their respective benefits:

Match the following groups with their respective benefits:

What is a significant cost associated with the production of the final prosthetic?

What is a significant cost associated with the production of the final prosthetic?

The impression taking stage can be eliminated if the patient already has a 3D scan.

The impression taking stage can be eliminated if the patient already has a 3D scan.

List one potential advantage of using additive manufacturing for producing prosthetics over traditional methods.

List one potential advantage of using additive manufacturing for producing prosthetics over traditional methods.

In the milling stage, key costs include staff salaries, laboratory time, and _____ for materials.

In the milling stage, key costs include staff salaries, laboratory time, and _____ for materials.

Match the stage of the prosthetic process with its associated people involved:

Match the stage of the prosthetic process with its associated people involved:

Which stage involves costs related to patient travel and accommodation?

Which stage involves costs related to patient travel and accommodation?

Adding value to the patient consultation can be achieved by scanning patients in batches.

Adding value to the patient consultation can be achieved by scanning patients in batches.

Identify one key stakeholder involved in the impression taking stage.

Identify one key stakeholder involved in the impression taking stage.

What is a primary drawback of traditional methods for producing customized devices?

What is a primary drawback of traditional methods for producing customized devices?

Non-contact methods for producing custom devices can help reduce patient anxiety during the fitting process.

Non-contact methods for producing custom devices can help reduce patient anxiety during the fitting process.

What is the purpose of a burn mask?

What is the purpose of a burn mask?

The traditional method to create a prosthetic socket involves making a physical _____ of the remaining limb.

The traditional method to create a prosthetic socket involves making a physical _____ of the remaining limb.

Match the following terms with their descriptions:

Match the following terms with their descriptions:

What is one of the psychological benefits of using non-contact methods?

What is one of the psychological benefits of using non-contact methods?

Additive manufacturing processes are considered slower than traditional methods for customized device production.

Additive manufacturing processes are considered slower than traditional methods for customized device production.

What type of manufacturing is often skilled-dependent and slow?

What type of manufacturing is often skilled-dependent and slow?

What is a potential benefit of localized scanning and manufacturing for prosthetics?

What is a potential benefit of localized scanning and manufacturing for prosthetics?

Using 3D printing for prosthetic sockets completely removes the need for manual steps in the process.

Using 3D printing for prosthetic sockets completely removes the need for manual steps in the process.

Name one stakeholder that must be considered when making decisions in the prosthetic fitting process.

Name one stakeholder that must be considered when making decisions in the prosthetic fitting process.

Minimizing the number of ________ in the prosthetic fitting process can benefit both patients and medical staff.

Minimizing the number of ________ in the prosthetic fitting process can benefit both patients and medical staff.

Which of the following may require adjustments to a prosthetic over time?

Which of the following may require adjustments to a prosthetic over time?

3D printed prosthetic sockets tend to be less expensive than traditional sockets.

3D printed prosthetic sockets tend to be less expensive than traditional sockets.

List one disadvantage of traditional mould-making for prosthetics.

List one disadvantage of traditional mould-making for prosthetics.

What is a benefit of using additive manufacturing in the medical field?

What is a benefit of using additive manufacturing in the medical field?

Additive manufacturing processes are primarily hazardous and cannot be used in an office environment.

Additive manufacturing processes are primarily hazardous and cannot be used in an office environment.

What is one potential bottleneck that can be reduced in the medical device manufacturing process?

What is one potential bottleneck that can be reduced in the medical device manufacturing process?

The _______ process in manufacturing includes activities like fitting and colour-matching for prosthetics.

The _______ process in manufacturing includes activities like fitting and colour-matching for prosthetics.

Match the following additive manufacturing processes with their primary feature:

Match the following additive manufacturing processes with their primary feature:

What does the term 'optimizing the schedule of work' in manufacturing refer to?

What does the term 'optimizing the schedule of work' in manufacturing refer to?

The overall cost of manufacturing a device is often only a small fraction of the total process cost.

The overall cost of manufacturing a device is often only a small fraction of the total process cost.

What are the two main processes involved in the production of a mould from a pattern?

What are the two main processes involved in the production of a mould from a pattern?

Flashcards

Why is there such a demand for medical applications?

Why is there such a demand for medical applications?

The increasing age of the population, rising survival rates for major illnesses, and cost restrictions all contribute to the growing demand for medical applications.

What are the innovations AM brings to the medical field?

What are the innovations AM brings to the medical field?

Additive Manufacturing (AM) can innovate by creating new products and process chains, impacting the production of both customized and mass-produced medical devices.

What are examples of customized medical devices?

What are examples of customized medical devices?

Customized medical devices like maxillofacial prostheses, dentures, orthotics, and artificial limbs cater to individual needs and ensure proper fit.

How are customized devices used in surgeries?

How are customized devices used in surgeries?

Signup and view all the flashcards

Why use AM for implants despite higher cost?

Why use AM for implants despite higher cost?

Signup and view all the flashcards

Geometric complexity

Geometric complexity

Signup and view all the flashcards

Fit to individual

Fit to individual

Signup and view all the flashcards

Weight saving

Weight saving

Signup and view all the flashcards

Fluid flow

Fluid flow

Signup and view all the flashcards

Cellular growth

Cellular growth

Signup and view all the flashcards

Traditional methods for custom medical devices

Traditional methods for custom medical devices

Signup and view all the flashcards

Burn mask

Burn mask

Signup and view all the flashcards

Traditional burn mask construction

Traditional burn mask construction

Signup and view all the flashcards

Digital technologies in Medical Devices

Digital technologies in Medical Devices

Signup and view all the flashcards

Digital patient modeling

Digital patient modeling

Signup and view all the flashcards

Customized medical device

Customized medical device

Signup and view all the flashcards

Benefits of digital technologies in healthcare

Benefits of digital technologies in healthcare

Signup and view all the flashcards

Digital technologies in maxillofacial prostheses

Digital technologies in maxillofacial prostheses

Signup and view all the flashcards

Traditional prosthetic mold-making

Traditional prosthetic mold-making

Signup and view all the flashcards

3D printed prosthetic socket

3D printed prosthetic socket

Signup and view all the flashcards

Stakeholders in prosthetic development

Stakeholders in prosthetic development

Signup and view all the flashcards

Process chain analysis

Process chain analysis

Signup and view all the flashcards

Streamlining consultations

Streamlining consultations

Signup and view all the flashcards

Localized prosthetic manufacturing

Localized prosthetic manufacturing

Signup and view all the flashcards

Benefits of 3D printed sockets

Benefits of 3D printed sockets

Signup and view all the flashcards

Optimizing the prosthetic process chain

Optimizing the prosthetic process chain

Signup and view all the flashcards

Patient Consultation

Patient Consultation

Signup and view all the flashcards

Impression Taking

Impression Taking

Signup and view all the flashcards

Scanning at Consultation

Scanning at Consultation

Signup and view all the flashcards

AM Advantages

AM Advantages

Signup and view all the flashcards

AM Limitations

AM Limitations

Signup and view all the flashcards

Tooling Route Prosthetics

Tooling Route Prosthetics

Signup and view all the flashcards

AM Prosthetics

AM Prosthetics

Signup and view all the flashcards

Customization

Customization

Signup and view all the flashcards

Additive Manufacturing (AM)

Additive Manufacturing (AM)

Signup and view all the flashcards

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM)

Signup and view all the flashcards

Medical Applications of AM

Medical Applications of AM

Signup and view all the flashcards

Custom Prosthetics

Custom Prosthetics

Signup and view all the flashcards

AM for Burn Masks

AM for Burn Masks

Signup and view all the flashcards

Digital Technologies in Healthcare

Digital Technologies in Healthcare

Signup and view all the flashcards

AM for Maxillofacial Prosthetics

AM for Maxillofacial Prosthetics

Signup and view all the flashcards

AM for Surgical Guides

AM for Surgical Guides

Signup and view all the flashcards

Study Notes

Additive Manufacturing - Medical Applications

- Additive manufacturing (AM) is a growing sector

- Factors contributing to the growth of AM in medicine include:

- Ageing population

- Increased survival rates for major diseases

- Cost constraints, particularly for the NHS

- Patient expectations

- High value (both financial and otherwise)

- AM is impacting medical devices in two areas

- Customised devices

- Mass-produced devices

- Focus on week is on customised medical devices

Examples of Customised Devices

- Maxillofacial prostheses

- Dentures

- Dental aligners

- Custom orthoses

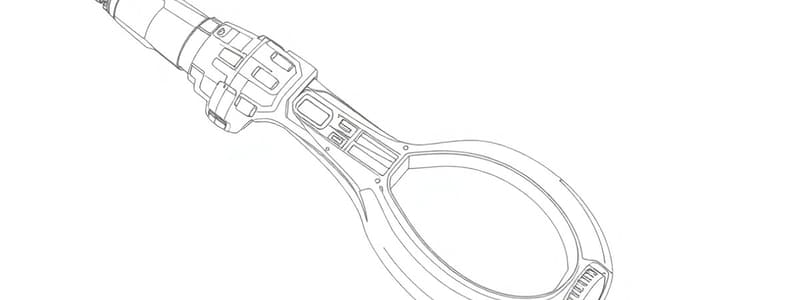

- Artificial limbs

- Burns splints

Customised Devices to Assist with Surgeries

- Drill guides

- Surgical planning models

Customised Implants

- AM devices can cost more than traditional devices, but

- Benefits of AM can be geometric complexity, fit to individual, weight saving, and fluid flow

- Considerations of the overall process chain need to be considered

Traditional Methods

- Often hand-made

- Labour-intensive

- Skill-dependent

- Slow

- Can be inaccurate

- May involve one or more visits to a specialist

- Can involve adjustments/replacement if fit is incorrect

- May involve physical contact

Examples of Traditional Methods - Burn Masks

- Traditional burn mask construction using plaster to create a mould and then a plastic mask

- Can be painful

- Patients may become anxious

Traditional Method of Construction - Benefits & Considerations

- Benefits include effectiveness

- Disadvantages include the physical contact, pain, and patient anxiety during the process

- Potential alternatives involve non-contact scanning & AM to create a user-friendly mould process, but this potentially incurs higher financial costs

Traditional Method of Production - Prosthetic Legs

- Steps involve producing a physical mould of the remaining limb, followed by manual finishing, creation of a socket, and alignment

- Procedure can be performed in a load-bearing situation and can be painful soon after injury

- Consider using AM to 3D print the socket

- Consider potential advantages & disadvantages and the stakeholder impact

Stakeholders

- Patients

- Carers/family

- Medical staff

- NHS (consider how considerations might differ in various countries)

- Other stakeholders (employers, colleagues, government)

Benefits of using AM in different stakeholders

- Patient: Less travel, reduced time away from work, less stress, more patients serviced

- Medical Staff: Higher patient throughput, focus on specialist input

- NHS: Reduction in missed appointments, lower transport costs, shorter waiting lists

AM Opportunities

- Minimise number of consultations

- Localise Scanning & Manufacture

- Reduce manual labour

AM - Maxillofacial Prostheses

- This particular form of prostheses is designed to match location, geometry, and colour

- Using digital technologies for value addition at each stage

- Tooling routes

Stages of AM Process

- People involved & Costs: A breakdown of the people who are typically involved in each stage and the associated costs for a prostheses production

- Patient Consultation

- Impression Taking

- Design and Manufacture of Pattern

- Production of Mould from Pattern

- Production of Final Prosthetic (Colour Matching & Fitting)

- Opportunities : Scan patient at consultation, eliminate patient visit, remove stages (eg. 3D CAD & AM to produce), the same for production of mould, same for production of final prosthetic

Summary of AM

- AM is often not the full cost of treatment, though it is a small fraction of the overall cost

- There are potential bottlenecks

- Identify the stakeholders and the potential benefits to everyone involved in treatment

- Consider the pros and cons of different AM applications to identify appropriate procedures

Other 'Non-Metals'

- Different materials are considered for AM.

- Despite current limitations, new developments are coming through

- All processes require understanding of material properties to be viable

Sheet Lamination

- Arguably the simplest AM process

- Profiles of cross-sections are cut from sheet materials, then stacked or bonded

- No single system; various methods of bonding

- Patenting is not possible due to the method’s simplicity

- Any material available in plate or sheet form is possible

EOS Laser Sintering

- Coate foundry sand

- Used to produce one-off castings

- Developed to help BMW make engine blocks

- Multiple similar processes

Direct Shell Production Casting

- Based on MIT 3D printing principle

- Creates investment casting shells directly

- Parts will need some post-production finishing

Figulo

- Ceramic process based on MIT 3D Printing technology

- Several design restrictions

- Low detail; no moving parts/assemblies

- Certain geometries difficult to produce

- Parts glazed after production

Medical Materials (Applications)

- Sterilizable devices (surgical equipment etc)

- Bio-compatible materials

- Bio-absorbable materials

- Bio-active materials

Construction (Applications)

- Production of emergency housing

- More complex architecture

- Ventilation incorporation

- Pipe-work

- Termite mounds

Solarsinter

- Combine sun & sand to fuse silica (Desert)

- Sustainable process for future

'Moondust'

- Consider transportation of materials

- Use of the Moon's materials in AM (e.g. Laser Sintering)

Food (Applications)

- Market for personalised food

- Food for long-term missions

- Ability to create taste, consistency, and aesthetics

Ashes (Applications)

- Laser sintering of ashes for keepsake

Additional Considerations

- The shift in some instances away from one machine doing everything in AM processes

- Identifying specific applications appropriate for specific AM processes

- Consider the potential of the following slides in other non-metal applications

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.