Podcast

Questions and Answers

What is deformation primarily caused by?

What is deformation primarily caused by?

- Temperature changes

- Chemical reactions

- Stress induced within the material (correct)

- External pressure alone

How is strain defined mathematically?

How is strain defined mathematically?

- Deformation multiplied by original length

- Change in mass divided by original mass

- Change in volume divided by original volume

- Change in length divided by original length (correct)

Which type of stress corresponds with elongation in the material?

Which type of stress corresponds with elongation in the material?

- Compressive stress

- Transverse stress

- Torsional stress

- Tensile stress (correct)

What characterizes elastic strain?

What characterizes elastic strain?

Which statement accurately describes plastic strain?

Which statement accurately describes plastic strain?

During which type of stress would one expect a reduction in length?

During which type of stress would one expect a reduction in length?

What distinguishes elastic and plastic strains at the atomic level?

What distinguishes elastic and plastic strains at the atomic level?

Which type of stress is specifically mentioned as creating shear stresses in the body?

Which type of stress is specifically mentioned as creating shear stresses in the body?

What physical property describes the ability of a material to be drawn into wires without fracture?

What physical property describes the ability of a material to be drawn into wires without fracture?

What is the term used for the localized reduction in cross-sectional area at the fracture site of ductile materials?

What is the term used for the localized reduction in cross-sectional area at the fracture site of ductile materials?

How is the percent elongation of a material calculated?

How is the percent elongation of a material calculated?

Which of the following materials would be classified as brittle based on elongation properties?

Which of the following materials would be classified as brittle based on elongation properties?

What characteristic distinguishes ductile materials from brittle materials during deformation?

What characteristic distinguishes ductile materials from brittle materials during deformation?

What is the SI unit of force?

What is the SI unit of force?

Which type of force is directed towards each other and produces compressive stress?

Which type of force is directed towards each other and produces compressive stress?

What does stress represent in mechanical properties?

What does stress represent in mechanical properties?

If two forces act on a body in opposite directions, what kind of resultant force is created?

If two forces act on a body in opposite directions, what kind of resultant force is created?

How is stress (σ) mathematically defined?

How is stress (σ) mathematically defined?

When two forces are applied parallel to each other but in opposite directions, what kind of resultant force is produced?

When two forces are applied parallel to each other but in opposite directions, what kind of resultant force is produced?

When a force is applied to a body that leads to a change in position or shape, this force is known as?

When a force is applied to a body that leads to a change in position or shape, this force is known as?

What property describes the behavior of materials under load?

What property describes the behavior of materials under load?

What defines the elastic limit of a material?

What defines the elastic limit of a material?

At what point on the stress-strain curve is the yield strength located?

At what point on the stress-strain curve is the yield strength located?

What is the significance of percent offset when measuring yield strength?

What is the significance of percent offset when measuring yield strength?

What should occur during the construction of an appliance using wire?

What should occur during the construction of an appliance using wire?

What is regarded as functional failure in a restoration?

What is regarded as functional failure in a restoration?

What happens to a material when it exceeds its yield strength?

What happens to a material when it exceeds its yield strength?

How is the yield strength defined?

How is the yield strength defined?

What occurs if a material is stressed beyond its ultimate strength?

What occurs if a material is stressed beyond its ultimate strength?

What distinguishes the fracture process of a brittle material from a ductile material?

What distinguishes the fracture process of a brittle material from a ductile material?

Which statement correctly defines resilience?

Which statement correctly defines resilience?

Which material is likely to exhibit ductile fracture?

Which material is likely to exhibit ductile fracture?

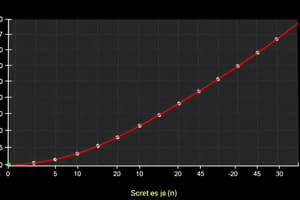

How is toughness represented in the stress-strain curve?

How is toughness represented in the stress-strain curve?

How does resilience relate to orthodontic wires?

How does resilience relate to orthodontic wires?

What characterizes the toughness of a material?

What characterizes the toughness of a material?

What are the primary characteristics of a brittle material during deformation?

What are the primary characteristics of a brittle material during deformation?

Which of the following describes what happens when load is removed from a resilient material?

Which of the following describes what happens when load is removed from a resilient material?

Flashcards are hidden until you start studying

Study Notes

Mechanical Properties

- Mechanical properties describe how materials behave under force or load.

- Force produces or tends to produce a change in a body's position, movement, or shape.

- Force is characterized by magnitude, speed (static/dynamic), point of application, and direction.

- Stress is the internal reaction to an external force, equal in intensity and opposite in direction to the applied force.

- Stress is calculated as force per unit area.

- Deformation is the distortion produced by stress within a material.

- Strain is the change in length per unit length, calculated as deformation/original length.

- Strain can be elastic (reversible) or plastic (permanent).

- Elastic strain involves stretching without breaking chemical bonds between atoms.

- Plastic strain involves the breaking and formation of new bonds, causing permanent changes in atomic arrangement.

- The elastic limit is the maximum stress a material can withstand without permanent deformation.

- The proportional limit is the point where stress becomes non-proportional to strain.

- The yield strength is the stress at which a small amount of permanent strain occurs.

- Ultimate strength is the maximum stress a material can withstand before failure.

- Fracture strength is the stress at which a material breaks.

- Malleability is the ability of a material to be deformed under compressive force without fracture.

- Ductility is the ability of a material to be drawn into wires without fracture.

- Percent elongation measures the maximum amount of permanent deformation a material can exhibit.

- Brittle materials exhibit little plastic deformation and fracture near the proportional limit.

- Ductile materials exhibit large amounts of plastic deformation and fracture after significant deformation.

- Resilience is the energy required to deform a material to its proportional limit, represented by the area under the elastic portion of the stress-strain curve.

- Toughness is the energy required to break a material, represented by the area under the entire stress-strain curve.

- Toughest materials have high proportional limits and good ductility.

- Brittle materials are generally not tough.

Clinically Relevant Properties

- Orthodontic wires require high resilience for gradual tooth movement.

- Restorations should not be subjected to stresses exceeding their yield strength to avoid permanent deformation.

- Malleable materials facilitate shaping into sheets, while ductile materials are suitable for drawing into wires.

Other Important Concepts

- Shear stresses are generated within a material when forces are applied parallel to the surface.

- Torsional stress and transverse stress are generated in specific loading conditions.

- Necking is localized reduction in cross-sectional area at the fracture site, often observed in ductile materials.

- Dental gold alloys are typically ductile, while nickel-chromium alloys are considered brittle.

- Dental amalgam, cements, and ceramics are generally considered brittle materials.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.