Podcast

Questions and Answers

Which component of a marine diesel engine converts the piston's up-and-down motion into rotational motion?

Which component of a marine diesel engine converts the piston's up-and-down motion into rotational motion?

- Piston

- Crankshaft (correct)

- Combustion Chamber

- Cylinder

What is the main purpose of the cooling system in a marine diesel engine?

What is the main purpose of the cooling system in a marine diesel engine?

- To convert fuel into energy

- To maintain engine temperature within regulated limits (correct)

- To compress air before combustion

- To store fuel for combustion

Which type of marine diesel fuel is typically used in larger vessels and requires heating before its usage?

Which type of marine diesel fuel is typically used in larger vessels and requires heating before its usage?

- Low Sulfur Fuels

- Biodiesel

- HFO (Heavy Fuel Oil) (correct)

- MDO (Marine Diesel Oil)

During routine maintenance, how often should oil changes typically be performed?

During routine maintenance, how often should oil changes typically be performed?

What is the primary function of fuel filters in the maintenance of marine diesel engines?

What is the primary function of fuel filters in the maintenance of marine diesel engines?

What characterizes MDO (Marine Diesel Oil) among marine fuels?

What characterizes MDO (Marine Diesel Oil) among marine fuels?

Which component of a marine diesel engine is primarily responsible for igniting the fuel after it is injected?

Which component of a marine diesel engine is primarily responsible for igniting the fuel after it is injected?

What maintenance action is crucial to ensure the proper functioning of the engine's cooling system?

What maintenance action is crucial to ensure the proper functioning of the engine's cooling system?

Flashcards are hidden until you start studying

Study Notes

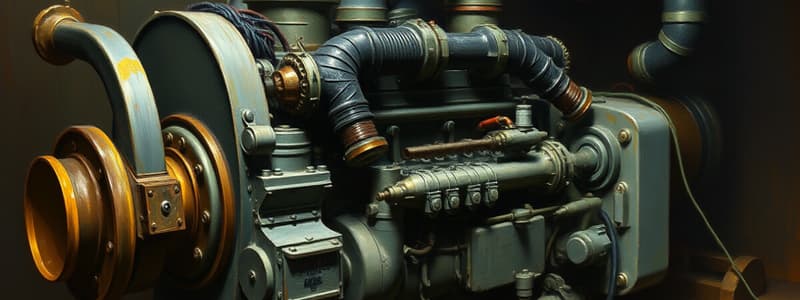

Engine Operation

- Basic Principle: Marine diesel engines operate on the four-stroke or two-stroke cycle, converting fuel energy into mechanical energy.

- Components:

- Cylinders: Where combustion occurs.

- Pistons: Move within the cylinders to create mechanical energy.

- Crankshaft: Converts up-and-down piston motion into rotational motion.

- Combustion Process:

- Air is compressed in the cylinder, raising temperature.

- Fuel is injected into the compressed air, igniting due to high temperature.

- Expansion of combustion gases pushes the piston down.

- Starting Systems: Typically include electrical (starter motors) or air systems (air start motors).

- Cooling Systems: Keep engine temperature regulated, often using seawater or freshwater cooling circuits.

Fuel Types

- Marine Diesel Fuel: Typically classified into two main types:

- MDO (Marine Diesel Oil): A blend of diesel and marine gas oil, suitable for most applications.

- HFO (Heavy Fuel Oil): A thicker, residual oil used in larger vessels; requires heating before use.

- Biodiesel: An alternative fuel derived from renewable sources, can be mixed with traditional diesel fuels.

- Low Sulfur Fuels: Increasingly used to comply with international regulations to reduce emissions.

- Fuel Quality: Important to monitor for contaminants (water, particulates) to prevent engine damage.

Maintenance Procedures

- Routine Checks:

- Inspect oil levels, coolant, and fuel systems regularly.

- Monitor gauges (temperature, pressure) during operation.

- Oil Changes: Typically every 250-500 hours of operation to ensure engine lubrication and performance.

- Filter Maintenance:

- Replace fuel filters and oil filters periodically.

- Check air filters for cleanliness to maintain airflow.

- Cooling System Maintenance:

- Flush and replace coolant as needed.

- Inspect and clean heat exchangers.

- Engine Overhauls: Scheduled based on operating hours; includes inspecting/replacing pistons, injectors, and valves.

- Record Keeping: Maintain detailed logs of maintenance activities and engine performance for regulatory compliance and troubleshooting.

Engine Operation

- Marine diesel engines function on either a four-stroke or two-stroke cycle, converting fuel energy into mechanical power.

- Cylinders serve as combustion chambers where the fuel-air mixture ignites.

- Pistons generate mechanical energy by moving within the cylinders during combustion.

- The crankshaft transforms the piston's vertical movement into rotational force.

- During combustion, air is compressed, raising its temperature, before fuel is injected and ignited by the heat.

- The expansion of combustion gases drives the piston downward.

- Starting systems generally include electric starters or air start motors for initiating engine operation.

- Cooling systems are essential to regulate engine temperature, utilizing seawater or freshwater circuits for effective heat management.

Fuel Types

- Marine diesel fuels are primarily categorized into MDO (Marine Diesel Oil) and HFO (Heavy Fuel Oil).

- MDO is a mixture of diesel and marine gas oil, well-suited for various applications.

- HFO is a denser residual oil typically used in larger vessels, requiring pre-heating to ensure flow.

- Biodiesel is an eco-friendly alternative sourced from renewable materials, which can be blended with conventional diesel.

- Low sulfur fuels are increasingly adopted to meet international regulations aimed at reducing emissions.

- Monitoring fuel quality for contaminants like water and particulates is crucial to avoid engine damage.

Maintenance Procedures

- Regular routine checks should include inspections of oil levels, coolant, and fuel systems.

- Gauges for temperature and pressure need to be monitored closely during engine operation.

- Oil changes are recommended every 250-500 hours to maintain optimal engine function and lubrication.

- Fuel and oil filters should be replaced periodically; air filters should be kept clean to ensure proper airflow.

- Cooling systems require regular flushing and coolant replacement, along with cleaning of heat exchangers.

- Scheduled engine overhauls are based on operational hours, focusing on inspecting and possibly replacing pistons, injectors, and valves.

- Detailed record-keeping of maintenance activities and engine performance is essential for regulatory compliance and effective troubleshooting.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.