Podcast

Questions and Answers

What is forming?

What is forming?

A mechanical deformation process on metals where the workpiece is reshaped without adding or removing material.

What is the carbon content of low-carbon steel?

What is the carbon content of low-carbon steel?

- Under 0.3 percent (correct)

- Between 0.6 and 2 percent

- Between 0.3 and 0.6 percent

- More than 2 percent

What process applies stresses that exceed the yield strength of the metal?

What process applies stresses that exceed the yield strength of the metal?

- Plastic deformation

- Sheet metalworking

- Bulk deformation (correct)

- Casting

Hot working and cold working both improve the strength of metals during shape changes.

Hot working and cold working both improve the strength of metals during shape changes.

What are the advantages of bulk deformation processes?

What are the advantages of bulk deformation processes?

Volume/bulk deformation processes change the shape of the metal workpiece without changing its ______.

Volume/bulk deformation processes change the shape of the metal workpiece without changing its ______.

What are the basic types of metal forming processes?

What are the basic types of metal forming processes?

Match the following forming processes with their descriptions:

Match the following forming processes with their descriptions:

Which of the following is a type of rolling process?

Which of the following is a type of rolling process?

Flashcards are hidden until you start studying

Study Notes

Manufacturing Processes II - Forming Technology

- Forming Definition: A mechanical deformation process that reshapes metals without adding or removing material.

- Forming Mechanism: Uses plastic deformation to change the shape of workpieces, maintaining their mass.

Types of Forming Processes

- Volume/Bulk Deformation: Involves shape changes through plastic deformation using applied forces.

- Material Forms: Typically starts with cylindrical bars, billets, or rectangular slabs.

- Temperature Classification: Includes cold forming, warm forming, and hot forming.

Effects of Carbon in Steel

- Low-Carbon Steel: Contains <0.3% carbon; noted for being cost-effective, easily weldable, and machinable.

- Medium-Carbon Steel: Contains 0.3%-0.6% carbon; balances workability, cost, and durability; commonly used in automotive applications.

- High-Carbon Steel: Contains 0.6%-2% carbon; very hard, used for tools and blades; more brittle and challenging to machine.

Bulk Deformation Processes

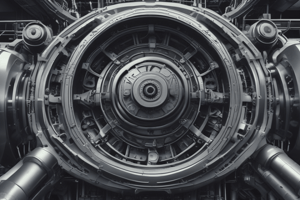

- Rolling: Thickness reduction through compressive forces from opposing rolls.

- Forging: Squeezing and shaping material between dies.

- Extrusion: Material is pushed through a die to take its shape.

- Wire and Bar Drawing: Diameter reduction by pulling material through dies.

Rolling Process

- Definition: Reduces thickness using compressive forces from rolls.

- Mill Configurations: Various designs for different rolling needs, including flat rolling and shape rolling.

- Types of Rolling:

- Flat Rolling: Reduces thickness of rectangular sections.

- Shape Rolling: Forms complex shapes (e.g., I-beams).

- Hot Rolling: Common for significant deformation; increases ductility.

- Cold Rolling: Produces finished sheets with improved surface finish.

Thread Rolling

- Process: Forms threads on cylindrical parts using dies; favorable for mass production of bolts and screws.

- Advantages: Higher production rates, material savings, strong threads due to work hardening, and improved fatigue resistance.

Ring Rolling

- Process: Thick-walled rings are transformed into thinner, larger diameter rings, used in bearings and pressure vessels.

- Advantages: Material savings, ideal grain orientation, and strengthened properties through cold working.

Shape Rolling

- Process: Gradually forms materials into contoured cross sections like I-beams and channels.

Gear Rolling

- Similar to Thread Rolling: Uses multiple gears to form gear profiles on metal.

General Considerations

- Desirable Material Properties for Forming: Low yield strength and high ductility, both influenced by temperature during the process.

- Work Hardening: Metal becomes stronger and more resistant to deformation with increased strain hardening.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.