Podcast

Questions and Answers

Which type of manufacturing layout focuses on arranging equipment and workstations based on the functions they perform?

Which type of manufacturing layout focuses on arranging equipment and workstations based on the functions they perform?

- Functional layout (correct)

- Cellular layout

- Project layout

- Flow layout

Which type of manufacturing layout arranges equipment and workstations based on the sequence of operations for a product?

Which type of manufacturing layout arranges equipment and workstations based on the sequence of operations for a product?

- Flow layout (correct)

- Cellular layout

- Functional layout

- Project layout

Which type of manufacturing layout arranges equipment and workstations in a way that allows for the efficient flow of materials and minimizes movement and transportation?

Which type of manufacturing layout arranges equipment and workstations in a way that allows for the efficient flow of materials and minimizes movement and transportation?

- Cellular layout (correct)

- Functional layout

- Project layout

- Flow layout

Which type of layout is characterized by linking together general purpose equipment to produce a single product?

Which type of layout is characterized by linking together general purpose equipment to produce a single product?

Which type of layout is characterized by a fixed layout and flow, with equipment too costly to move?

Which type of layout is characterized by a fixed layout and flow, with equipment too costly to move?

What is the expected life of a layout?

What is the expected life of a layout?

What factors should be considered when developing a layout?

What factors should be considered when developing a layout?

Which type of product requires a large number of input materials to make a small variety of final products?

Which type of product requires a large number of input materials to make a small variety of final products?

What factors determine the best fit for a company's operations?

What factors determine the best fit for a company's operations?

What type of factory layout focuses on grouping machines based on their functions?

What type of factory layout focuses on grouping machines based on their functions?

What type of factory layout is suitable for low variety and high volume continuous manufacturing?

What type of factory layout is suitable for low variety and high volume continuous manufacturing?

Which type of manufacturing layout arranges equipment and workstations based on the sequence of operations for a product?

Which type of manufacturing layout arranges equipment and workstations based on the sequence of operations for a product?

What type of factory layout focuses on grouping machines based on their functions?

What type of factory layout focuses on grouping machines based on their functions?

Which type of product requires a large number of input materials to make a small variety of final products?

Which type of product requires a large number of input materials to make a small variety of final products?

Which type of manufacturing layout is characterized by a fixed layout and flow, with equipment too costly to move?

Which type of manufacturing layout is characterized by a fixed layout and flow, with equipment too costly to move?

What is the primary characteristic of a functional layout?

What is the primary characteristic of a functional layout?

What factors should be considered when developing a layout?

What factors should be considered when developing a layout?

What is the main advantage of a product layout?

What is the main advantage of a product layout?

Which type of product requires a small number of raw materials to result in a large variety of final products?

Which type of product requires a small number of raw materials to result in a large variety of final products?

What is the primary difference between an electric drill and a drill press in terms of production?

What is the primary difference between an electric drill and a drill press in terms of production?

Which type of manufacturing layout arranges equipment in a fixed sequence and supports low variety and high volume continuous manufacturing?

Which type of manufacturing layout arranges equipment in a fixed sequence and supports low variety and high volume continuous manufacturing?

When variety and volume are medium, which type of manufacturing layout groups products into families and operates autonomously?

When variety and volume are medium, which type of manufacturing layout groups products into families and operates autonomously?

Flashcards are hidden until you start studying

Study Notes

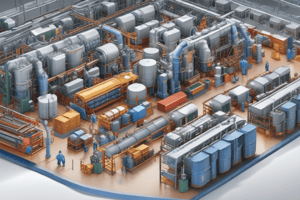

Manufacturing Layout Types

- Functional Layout: focuses on arranging equipment and workstations based on the functions they perform

- Product Layout: arranges equipment and workstations based on the sequence of operations for a product

- Process Layout: arranges equipment and workstations in a way that allows for the efficient flow of materials and minimizes movement and transportation

- Fixed Position Layout: characterized by linking together general-purpose equipment to produce a single product

- Fixed Layout: characterized by a fixed layout and flow, with equipment too costly to move

Factors to Consider and Characteristics

- Layout development should consider factors such as material flow, equipment, personnel, and production volume

- Expected life of a layout is typically 5-10 years

- Functional Layout is suitable for high variety and low volume production

- Product Layout is suitable for low variety and high volume continuous manufacturing

- Primary characteristic of a Functional Layout is grouping machines based on their functions

- Primary advantage of a Product Layout is efficiency gained through continuous production

- Fixed Position Layout is used for large and complex products, such as ships and buildings

Product Characteristics

- Standard Products: require a small number of raw materials to result in a small variety of final products

- Custom Products: require a large number of input materials to make a small variety of final products

- Mass Customization: requires a small number of raw materials to result in a large variety of final products

Production Differences

- The primary difference between an electric drill and a drill press is the level of customization and production volume

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.