Podcast

Questions and Answers

¿Qué tipo de diseño de planta organiza las estaciones de trabajo alrededor de la secuencia de operaciones requeridas para completar cada trabajo?

¿Qué tipo de diseño de planta organiza las estaciones de trabajo alrededor de la secuencia de operaciones requeridas para completar cada trabajo?

Diseño de proceso

¿Cuál es el objetivo principal de la fabricación Lean (Lean Manufacturing)?

¿Cuál es el objetivo principal de la fabricación Lean (Lean Manufacturing)?

Eliminar desperdicios

¿Qué tipo de distribución de producción implica organizar las estaciones de trabajo a lo largo de un camino continuo para procesar una gran cantidad de artículos similares?

¿Qué tipo de distribución de producción implica organizar las estaciones de trabajo a lo largo de un camino continuo para procesar una gran cantidad de artículos similares?

Diseño de línea

¿Qué tipo de distribución de producción es adecuado para la fabricación personalizada donde se utilizan máquinas individuales de manera flexible?

¿Qué tipo de distribución de producción es adecuado para la fabricación personalizada donde se utilizan máquinas individuales de manera flexible?

¿En qué consiste la estrategia Make-To-Order (MTO) y cuándo es comúnmente utilizada?

¿En qué consiste la estrategia Make-To-Order (MTO) y cuándo es comúnmente utilizada?

¿Qué son las celdas de producción y cuál es su propósito?

¿Qué son las celdas de producción y cuál es su propósito?

¿Qué es el balanceo de línea (Line Balancing) y por qué es importante en la optimización de procesos de producción?

¿Qué es el balanceo de línea (Line Balancing) y por qué es importante en la optimización de procesos de producción?

Cual es el papel del Takt Time en el balanceo de lineas?

Cual es el papel del Takt Time en el balanceo de lineas?

Cual sistema de producción es mas susceptible para el balanceo de lineas?

Cual sistema de producción es mas susceptible para el balanceo de lineas?

Cual es la diferencia entre administración de operaciones y administración de producción?

Cual es la diferencia entre administración de operaciones y administración de producción?

Flashcards are hidden until you start studying

Study Notes

Operations Management and Key Concepts

Operations management is a critical aspect of any business because it involves planning, organizing, directing, and controlling resources and activities within an organization to achieve specific objectives. It encompasses various aspects such as quality control, inventory management, logistics, supply chain management, human resource management, technology management, and more. Here, we will focus on some key concepts related to operations management, specifically plant layout, operations management, production distribution, production cells, and line balancing.

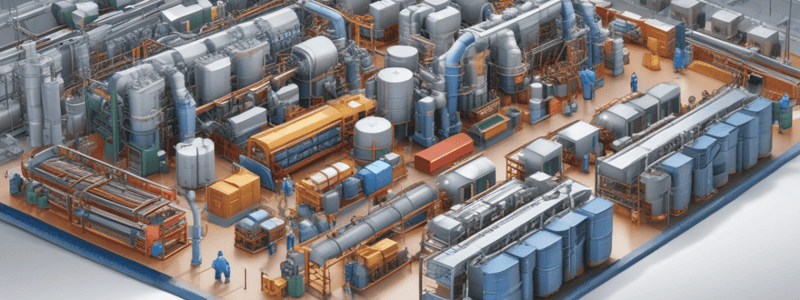

Plant Layout

The design of a manufacturing facility's physical space (plant layout) can significantly influence its efficiency, productivity, and safety. There are two primary types of plant layouts: process (or cellular) and product (line):

Process Layout

In this design, workstations are arranged around the sequence of operations required to complete each job, which can be ideal for high-volume, low-mix production processes:

- Job shop layout: This arrangement is suitable for custom manufacturing where individual machines are used in a flexible manner

- Process flow layout: In this type, work centers and departments are organized in the order that materials flow through the system

Product Layout

Product (line) layout refers to an arrangement that organizes machine tools and workers along a single line, often associated with mass production systems:

- Line layout: This involves arranging equipment and work stations along a continuous path to process a large number of similar items, optimizing efficiency

Operations Management

Operations management strategies include several techniques that aim to improve productivity and reduce costs while maintaining quality standards:

Lean Manufacturing

Lean manufacturing aims to eliminate waste within a manufacturing process by using techniques such as just-in-time production and continuous improvement to optimize efficiency:

Six Sigma

This quality management strategy seeks to improve the quality of the output of a process by identifying and removing causes of defects (errors) and minimizing variability in business processes

Production Distribution

Production distribution refers to how products or services are distributed from their point of origin to the end consumer. Strategies for efficient production distribution include:

- Just-In-Time (JIT): This method emphasizes reducing inventory levels by only ordering components when needed, which can help reduce costs and minimize wasted resources

- Make-To-Order (MTO): In this approach, each order is customized according to customer requirements, often used in industries that offer high-value, personalized products

Production Cells

Production cells refer to specific configurations of machines, equipment, work areas, and workers designed to maximize productivity and flexibility in the production line:

Single-Minute Exchange of Dies (SMED)

SMED aims to streamline the process of setting up machinery between different production runs to increase capacity without increasing working hours

Line Balancing

Line balancing is the process of arranging tasks on a production line so that they are equitably distributed among available labor units, with the goal of achieving optimal efficiency:

- Methods for line balancing: Various methods exist to balance lines, including mathematical algorithms and statistical tools

These concepts play a crucial role in operations management, helping businesses achieve greater efficiency, productivity, and cost savings while maintaining high-quality standards. By understanding these key principles, organizations can make informed decisions about their operational strategies and optimize their production processes accordingly.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.