Podcast

Questions and Answers

Which approaches are used in the development of maintenance programs in commercial aviation?

Which approaches are used in the development of maintenance programs in commercial aviation?

- Process-oriented approach

- Task-oriented approach

- Both A and B (correct)

- None of the above

The commercial aviation industry has shifted to the process-oriented approach for newer airplane models.

The commercial aviation industry has shifted to the process-oriented approach for newer airplane models.

False (B)

What are the three primary maintenance processes used in the process-oriented approach?

What are the three primary maintenance processes used in the process-oriented approach?

Hard time (HT), On-condition (OC), Condition monitoring (CM)

What does Hard Time (HT) refer to in maintenance?

What does Hard Time (HT) refer to in maintenance?

What is the focus of the Maintenance Steering Group (MSG) approach?

What is the focus of the Maintenance Steering Group (MSG) approach?

Condition Monitoring (CM) is a process used for components that can utilize both HT and OC processes.

Condition Monitoring (CM) is a process used for components that can utilize both HT and OC processes.

Which aircraft used the MSG approach and later adapted to the MSG-2?

Which aircraft used the MSG approach and later adapted to the MSG-2?

What is the primary role of reliability programs in aviation maintenance?

What is the primary role of reliability programs in aviation maintenance?

The maintenance steering group (MSG) approach was developed starting with the Boeing _____ in 1968.

The maintenance steering group (MSG) approach was developed starting with the Boeing _____ in 1968.

What does On-condition (OC) maintenance entail?

What does On-condition (OC) maintenance entail?

Flashcards are hidden until you start studying

Study Notes

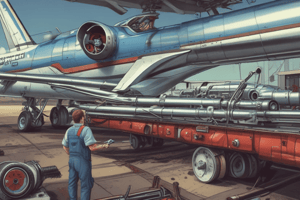

Development of Maintenance Programs

- Two primary approaches for developing maintenance programs in commercial aviation: process-oriented and task-oriented.

- Distinctions between the approaches include attitudes toward maintenance actions and assignment methods for maintenance tasks.

- Newer airplane models largely adopt the task-oriented approach, while older models typically utilize the process-oriented approach.

- McDonnell-Douglas and Boeing offer new task-oriented maintenance programs for older aircraft, available for operators to purchase.

Maintenance Processes

- Process-oriented maintenance incorporates three primary types:

- Hard Time (HT): For components with defined lifespan limits.

- On-Condition (OC): For components with detectable wear-out characteristics.

- Condition Monitoring (CM): Applies to non-HT or non-OC components, focusing on tracking failure rates for prediction and prevention.

- Task-oriented maintenance is based on predefined tasks aimed at preventing in-service failures; equipment redundancies may allow for failures without compromising safety.

- Reliability programs address components with unpredictable failure rates and no scheduled tasks, offering more sophisticated oversight than CM.

Maintenance Steering Group (MSG) Approach

- Originated in 1968 with the development of the Boeing 747, signaling a new era in aviation maintenance programming.

- Collaboration involved Boeing, suppliers, airlines, and the FAA in creating a more advanced maintenance framework.

- Six industry working groups (IWGs) focused on specific aircraft systems: structures, mechanical systems, engines and APU, electrical and avionics, flight controls and hydraulics, and zonal considerations.

- IWGs evaluated maintenance significant items (MSIs) and failure modes using a logic tree to establish maintenance requirements.

- Employed a "bottom-up" approach, prioritizing components as key contributors to potential malfunctions.

MSG Approach Outcomes

- Initial success with the Boeing 747 led to adaptations for other aircraft under MSG-2, including Lockheed L-1011 and McDonnell-Douglas DC-10.

- Steps in the process involved identifying maintenance items, failure modes, functions, and assessing their applicability.

- Structured evaluations included initial sampling thresholds for structures and simplified process flow diagrams for maintenance tasks based on safety and maintenance check availability.

- Maintenance action frequency determined by analyzing data on failure and removal rates relevant to each component.

Process-Oriented Maintenance

- Decision logic procedures for process-oriented maintenance established by the Air Transport Association of America (ATA).

- MSG-2 approach emphasizes a detailed analysis of each aircraft unit, categorizing them into HT, OC, or CM.

- Hard Time (HT) requires item removal at planned intervals (flight hours, cycles, or calendar time).

- On-Condition (OC) involves checking items based on specified intervals for serviceability assessment.

- Condition Monitoring (CM) focuses on tracking parameters like failure and removal rates to enhance maintenance planning.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.