Podcast

Questions and Answers

What is the primary purpose of dressing for safety in the drill press operation?

What is the primary purpose of dressing for safety in the drill press operation?

- To enhance workpiece quality

- To reduce machine maintenance

- To prevent personal injuries (correct)

- To improve machine performance

What is the formula to calculate RPM in the drill press operation?

What is the formula to calculate RPM in the drill press operation?

- RPM drive x Diameter of Drive Pulley = RPM of the driven ÷ Driven Pulley Diameter (correct)

- RPM drive - Diameter of Drive Pulley = RPM of the driven + Driven Pulley Diameter

- RPM drive + Diameter of Drive Pulley = RPM of the driven - Driven Pulley Diameter

- RPM drive ÷ Diameter of Drive Pulley = RPM of the driven ÷ Driven Pulley Diameter

What is the recommended action when changing the drill bit?

What is the recommended action when changing the drill bit?

- Always stop the spindle with your hand

- Use lubricants to cool the drill bit

- Never leave the key in the drill chuck (correct)

- Wear jewelry while operating the machine

What is the purpose of the sensitive drill press speed change mechanism?

What is the purpose of the sensitive drill press speed change mechanism?

What is a critical safety consideration when using keyed chucks or drill drifts?

What is a critical safety consideration when using keyed chucks or drill drifts?

What is the average speed range of the drill press?

What is the average speed range of the drill press?

What is the purpose of the upright/column speed change mechanism?

What is the purpose of the upright/column speed change mechanism?

What is a common hazard associated with forcing the drill bit too much?

What is a common hazard associated with forcing the drill bit too much?

What is the primary function of a drill press?

What is the primary function of a drill press?

What type of chuck is commonly used in a sensitive drill press?

What type of chuck is commonly used in a sensitive drill press?

What is the maximum hole diameter capacity of a sensitive drill press?

What is the maximum hole diameter capacity of a sensitive drill press?

What is the purpose of reaming?

What is the purpose of reaming?

What is the purpose of countersinking?

What is the purpose of countersinking?

What is the purpose of tapping?

What is the purpose of tapping?

What is the purpose of spot-facing?

What is the purpose of spot-facing?

What is the primary function of parallels on a drill press?

What is the primary function of parallels on a drill press?

What is the range of speeds commonly found on a sensitive drill press?

What is the range of speeds commonly found on a sensitive drill press?

What is the purpose of a drilling jig?

What is the purpose of a drilling jig?

What type of device is used to support long work pieces on a drill press table?

What type of device is used to support long work pieces on a drill press table?

What is the key characteristic of a drilling jig?

What is the key characteristic of a drilling jig?

What type of clamp is used to hold and locate round objects on a drill press?

What type of clamp is used to hold and locate round objects on a drill press?

What is the purpose of clamps and straps on a drill press?

What is the purpose of clamps and straps on a drill press?

Where should parallels be placed on a drill press?

Where should parallels be placed on a drill press?

What type of device is used to secure heavy and odd shaped work pieces on a drill press?

What type of device is used to secure heavy and odd shaped work pieces on a drill press?

What is the formula to determine the RPM of the spindle?

What is the formula to determine the RPM of the spindle?

What is the unit of feed rate in drilling?

What is the unit of feed rate in drilling?

What is the ideal chip shape in drilling?

What is the ideal chip shape in drilling?

What is the RPM calculation for manual machining in the metric system?

What is the RPM calculation for manual machining in the metric system?

What is the dependency of feed rate in drilling?

What is the dependency of feed rate in drilling?

What is the consequence of high feed rates in drilling?

What is the consequence of high feed rates in drilling?

What is the purpose of the formula RPM x Drive = RPM x Driven?

What is the purpose of the formula RPM x Drive = RPM x Driven?

When drilling large holes, what is the purpose of drilling a pilot hole?

When drilling large holes, what is the purpose of drilling a pilot hole?

What is the recommended size of the pilot hole compared to the size of the chisel edge of the larger drill?

What is the recommended size of the pilot hole compared to the size of the chisel edge of the larger drill?

What is the consequence of drilling a pilot hole that is too large?

What is the consequence of drilling a pilot hole that is too large?

What is the purpose of using a transfer punch when drilling mating components?

What is the purpose of using a transfer punch when drilling mating components?

What is the recommended method for supporting the workpiece when drilling round work on the periphery?

What is the recommended method for supporting the workpiece when drilling round work on the periphery?

What is the purpose of aligning the center punch mark with a rule or vernier caliper?

What is the purpose of aligning the center punch mark with a rule or vernier caliper?

What is the recommended diameter for drilling a pilot hole when the diameter is over?

What is the recommended diameter for drilling a pilot hole when the diameter is over?

What is the purpose of setting the drill bit into the center of the drilled hole and reversing the rotation direction?

What is the purpose of setting the drill bit into the center of the drilled hole and reversing the rotation direction?

Flashcards are hidden until you start studying

Study Notes

Drill Press Safety

- Dress safely for operations

- No jewelry, ensure eye safety, and hand safety

- Remove chips carefully, use proper work holding, and avoid forcing the drill bit

- Use lubricants, coolants, and be mindful of skin conditions

- Never leave the key in the drill chuck or attempt to stop the spindle with your hand

Drill Press Speed Change

- Average speed: 600-2800 RPM

- Sensitive drill press speed change: RPM drive x diameter of drive pulley = RPM of the driven x driven pulley diameter

- Example: 1800 x 4" diameter = 2400 RPM x 3" diameter

Column Type and Upright/Column Speed Change

- Set speed when machine is not running

- Variable RPM selector: RPM is set as machine is rotating

- Damage will occur if this is not followed

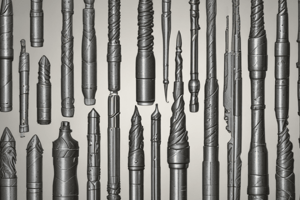

Drill Press Operations

- Drill press operation: drilling holes by turning a drill bit and plunging it downward into a work piece

- Drill press applications: machine reaming, hole sawing, machine tapping, boring operations, spot facing, counter boring, and counter sinking

Drill Press Types and Applications

- Sensitive drill press: capacity up to 5/8" hole diameter, keyed chuck, and speeds up to 3000 RPM

- Work piece capacity: distance from the column to the center of the drill point

- Table types: solid, rotation on the X axis, round tables rotate around the Z axis

- Clamps and straps: secure heavy and odd-shaped work pieces

Supporting Devices

- Parallels: elevate and support work pieces for drilling operations

- Clamping technique: ensure parallels are close to the drilling operation to prevent work piece bending

- V-blocks: hold and locate round objects on the drill press and milling machine

- Angle plates and clamps: support long work pieces onto the drill press table

RPM Calculations

- RPM calculation formula: RPM drive x diameter of drive pulley = RPM of the driven x driven pulley diameter

- Example: 1800 x 4" diameter = 2400 RPM x 3" diameter

- RPM calculation for the metric system: RPM = 1000 x CS / Dia for CNC and RPM = 320 x CS / Dia for manual machining

- Spindle RPM adjustment: RPM x drive = RPM x driven

Feed Rate for Drilling

- Feed rate is the velocity at which the cutter is fed or advanced against the work piece

- Feed rate is dependent on: type of tool, surface finish desired, power available, rigidity of the machine and tooling setup, strength of the workpiece, and characteristics of the material being cut

- Drilling feed rates: see table 3

Drilling Process

- Set drill bit into the center drilled hole and reverse the rotation direction

- Float the tool into the location, clamp the work piece, and verify alignment

- Use permanent layout as a reference point for accurate hole locations

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.