Podcast

Questions and Answers

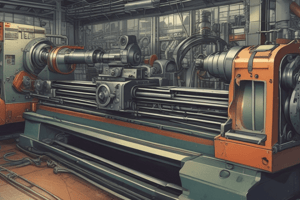

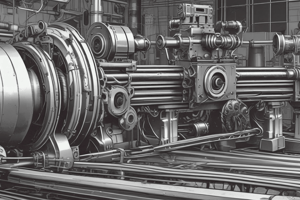

Show by drawing the basic movements of the various operating machine.

Show by drawing the basic movements of the various operating machine.

The basic movements of an operating machine can be illustrated by drawing a diagram showcasing the motion of its components, such as a rotating spindle, a reciprocating slide, or a feeding mechanism. The drawing should clearly depict the direction of the movement and any relevant points of reference.

What are the different types of chip and chip formation?

What are the different types of chip and chip formation?

The types of chip and chip formation depend on the cutting process and the materials being cut. Common types include continuous chips, segmented chips, discontinuous chips, and built-up edge chips. The formation process is influenced by factors like cutting speed, feed rate, tool geometry, and workpiece material.

Write what you know about the physical and mechanical properties of metal.

Write what you know about the physical and mechanical properties of metal.

Metals possess unique physical and mechanical properties like strength, hardness, ductility, malleability, and conductivity. These properties depend on the metal's composition, microstructure, and processing methods, and influence their suitability for different applications.

What are the different types of cooling fluids?

What are the different types of cooling fluids?

What do you know about marking, chiseling, hack sawing, filling, scraping, and drilling. What are the tools used in each operation?

What do you know about marking, chiseling, hack sawing, filling, scraping, and drilling. What are the tools used in each operation?

What are the main parts of the lathe and the function of each of them?

What are the main parts of the lathe and the function of each of them?

What do you know about lathe maintenance?

What do you know about lathe maintenance?

Mention the main reasons that lead to lathe accuracy.

Mention the main reasons that lead to lathe accuracy.

What are the methods for testing a lathe?

What are the methods for testing a lathe?

Mention what you know about the types and shapes of lathe tools and the operations they perform.

Mention what you know about the types and shapes of lathe tools and the operations they perform.

What are the materials used to make lathe tool and other tools?

What are the materials used to make lathe tool and other tools?

Show by drawing the angles of the cutting edge of lathe tool.

Show by drawing the angles of the cutting edge of lathe tool.

What are the wrong positions for the lathe tool?

What are the wrong positions for the lathe tool?

What are the factors that affect the life of the cutting edge?

What are the factors that affect the life of the cutting edge?

What is the importance of cooling and lubrication in various cutting operations?

What is the importance of cooling and lubrication in various cutting operations?

What do you know about carbide tipped tool?

What do you know about carbide tipped tool?

How is the inclined part made on the lathe?

How is the inclined part made on the lathe?

What are the safety methods that must be followed to maintain the safety of everyone who works in the workshops?

What are the safety methods that must be followed to maintain the safety of everyone who works in the workshops?

Flashcards

Lathe Turning

Lathe Turning

The process of removing material from a workpiece using a cutting tool, which is mounted on a lathe.

Lathe Operations

Lathe Operations

Lathes are used for various operations such as turning, facing, drilling, boring, threading, and knurling. These operations are performed by rotating the workpiece against a cutting tool.

Lathe

Lathe

A mechanical device used to remove material from a workpiece by rotating it against a cutting tool, achieving precise shapes and dimensions.

Turning

Turning

Signup and view all the flashcards

Facing

Facing

Signup and view all the flashcards

Drilling

Drilling

Signup and view all the flashcards

Boring

Boring

Signup and view all the flashcards

Threading

Threading

Signup and view all the flashcards

Knurling

Knurling

Signup and view all the flashcards

Spindle

Spindle

Signup and view all the flashcards

Carriage

Carriage

Signup and view all the flashcards

Toolpost

Toolpost

Signup and view all the flashcards

Motor Drive

Motor Drive

Signup and view all the flashcards

Speed Control

Speed Control

Signup and view all the flashcards

Feed Mechanisms

Feed Mechanisms

Signup and view all the flashcards

Cutting Fluid

Cutting Fluid

Signup and view all the flashcards

Cutting Operation

Cutting Operation

Signup and view all the flashcards

Cutting Edge

Cutting Edge

Signup and view all the flashcards

Cutting Tool Life

Cutting Tool Life

Signup and view all the flashcards

Lathe Maintenance

Lathe Maintenance

Signup and view all the flashcards

Study Notes

Lathe Operations and Tools

- Basic movements of various operating machines should be drawn

- Different types of chips and chip formation should be described

- Physical and mechanical properties of metal should be explained

- Types of cooling fluids should be identified

- Marking, chiseling, sawing, and drilling tools, and their uses should be described

- Lathe parts and their functions should be identified

- Lathe maintenance procedures should be described

- Reasons for lathe inaccuracy should be noted

- Lathe testing methods should be listed

- Lathe tool types and operations should be outlined

- Lathe tool materials should be identified

- Cutting edge angles should be illustrated

- Improper lathe tool positions should be identified

- Cutting edge life factors should be noted

- Importance of cooling and lubrication during cutting should be emphasized

- Carbide-tipped tools should be described

- Sequence and inclined part creation on a lathe should be described

- Screw part creation on a lathe should be described

- Tools for precise/ultra-precise measurements should be listed

- Calipers with different accuracies (0.1, 0.02, and 0.05) should be illustrated

- Types of micrometers should be listed

- Measurement gauge function should be defined

Safety in Workshops

- Safety methods for workshops need to be outlined

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.