Podcast

Questions and Answers

The lathe is only used for shaping and cutting wood.

The lathe is only used for shaping and cutting wood.

False (B)

The headstock is a type of tool used for turning techniques.

The headstock is a type of tool used for turning techniques.

False (B)

It is recommended to wear open-toed shoes while operating the lathe.

It is recommended to wear open-toed shoes while operating the lathe.

False (B)

The tailstock is used to support shorter workpieces.

The tailstock is used to support shorter workpieces.

The lathe bed should be kept at an angle to ensure proper operation.

The lathe bed should be kept at an angle to ensure proper operation.

Regularly sanding the workpiece after turning can improve surface quality.

Regularly sanding the workpiece after turning can improve surface quality.

An unbalanced workpiece can cause the lathe to vibrate excessively.

An unbalanced workpiece can cause the lathe to vibrate excessively.

Dull tools can cause a smooth surface finish.

Dull tools can cause a smooth surface finish.

Flashcards are hidden until you start studying

Study Notes

Safety Precautions

- Wear appropriate safety gear, including eye protection and hearing protection.

- Keep the work area well-lit and clutter-free.

- Familiarize yourself with emergency stop procedures.

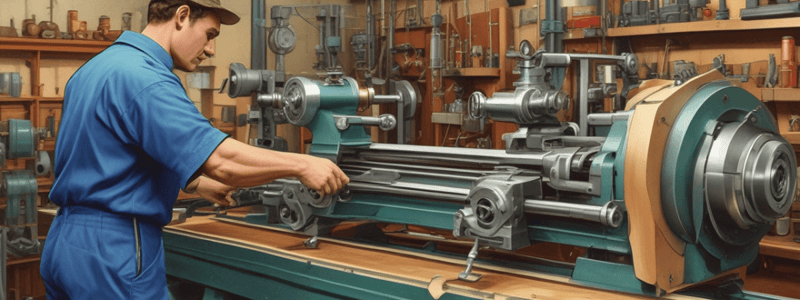

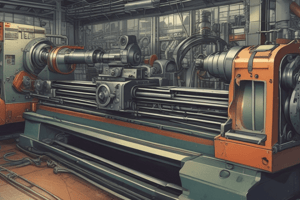

Lathe Components

- Bed: main component of the lathe.

- Headstock: houses the motor and spindle.

- Tailstock: supports longer workpieces.

- Tool rest: holds the cutting tool.

- Motor: powers the lathe.

Mounting Workpiece

- Secure the workpiece between the headstock and tailstock.

- Use the tailstock to support longer workpieces.

Lathe Operation

- Adjust the speed according to the material and project.

- Use the correct turning technique for the project.

Turning Techniques

- Spindle turning: turning a workpiece mounted between centers.

- Faceplate turning: turning a workpiece mounted on a faceplate.

- Bowl turning: turning a workpiece mounted on a faceplate, with the grain running perpendicular to the axis.

Maintenance and Lubrication

- Regularly clean and oil moving parts.

- Check belts, bearings, and pulleys for wear.

- Keep the lathe bed level and free from debris.

Troubleshooting

- Excessive vibration: check workpiece balance, lathe surface, and drive belt wear.

- Rough surface finish: check tool sharpness, lathe speed, and feed rate.

- Motor stall: reduce depth of cut, ensure proper voltage, and check belts and pulleys.

- Tailstock won't lock: clean quill and spindle, adjust locking mechanism, and lubricate moving parts.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.