Podcast

Questions and Answers

What safety measure should be taken regarding personal attire while operating a lathe machine?

What safety measure should be taken regarding personal attire while operating a lathe machine?

- Wear loose-fitting clothing to allow for movement

- Wear a watch for time management

- Use protective gloves

- Tie back long hair and remove loose clothing (correct)

Which tool or method is recommended for cleaning chips and coolant from the lathe?

Which tool or method is recommended for cleaning chips and coolant from the lathe?

- Water spraying

- Vacuum cleaner

- Hand wiping

- Compressed air or a brush (correct)

What is the primary risk of operating a lathe while under the influence of substances?

What is the primary risk of operating a lathe while under the influence of substances?

- Excessive wear on tools

- Increased likelihood of accidents and injuries (correct)

- Misalignment of workpieces

- Reduced productivity

Which component of the lathe machine is responsible for holding and rotating the workpiece?

Which component of the lathe machine is responsible for holding and rotating the workpiece?

What part of the lathe machine facilitates the adjustment of cutting tools?

What part of the lathe machine facilitates the adjustment of cutting tools?

What function does the spindle serve in a lathe machine?

What function does the spindle serve in a lathe machine?

Which statement regarding lathe machine operation is incorrect?

Which statement regarding lathe machine operation is incorrect?

What is a crucial step to take before using a lathe machine for the first time?

What is a crucial step to take before using a lathe machine for the first time?

What score range indicates a student has performed at a 'Very - Much Competent' level?

What score range indicates a student has performed at a 'Very - Much Competent' level?

Which statement is true regarding a score of 4 - 3?

Which statement is true regarding a score of 4 - 3?

What does a score of 6 - 5 indicate about a student's understanding of PPE?

What does a score of 6 - 5 indicate about a student's understanding of PPE?

Which score range reflects a 'Slightly Competent' level?

Which score range reflects a 'Slightly Competent' level?

What is indicated by a student receiving a score of 1 - 2?

What is indicated by a student receiving a score of 1 - 2?

What does the 'Criteria' column in the rubrics specifically address?

What does the 'Criteria' column in the rubrics specifically address?

In the context of the rubric, a deep understanding of PPE includes which aspect?

In the context of the rubric, a deep understanding of PPE includes which aspect?

Which statement best describes the level of competency for a score of 3 - 4?

Which statement best describes the level of competency for a score of 3 - 4?

What criteria must be met for a student to achieve a score of 8 - 7?

What criteria must be met for a student to achieve a score of 8 - 7?

Which formula correctly represents the relationship between cutting speed, diameter, and spindle speed?

Which formula correctly represents the relationship between cutting speed, diameter, and spindle speed?

The explanation of proper PPE must reflect which quality to achieve top scoring?

The explanation of proper PPE must reflect which quality to achieve top scoring?

What should be done to ensure the tool is functioning correctly before beginning machining?

What should be done to ensure the tool is functioning correctly before beginning machining?

What is the definition of feed rate in lathe machining?

What is the definition of feed rate in lathe machining?

What should be used for precise adjustments of the tool position and height?

What should be used for precise adjustments of the tool position and height?

During the machining operation, what should be closely monitored?

During the machining operation, what should be closely monitored?

What is the cut load per tooth related to in terms of lathe tool calculation?

What is the cut load per tooth related to in terms of lathe tool calculation?

How do you determine the feed rate from the feed per revolution?

How do you determine the feed rate from the feed per revolution?

What should be obtained before calculating cutting speed for the material being machined?

What should be obtained before calculating cutting speed for the material being machined?

What is the primary purpose of a facing operation?

What is the primary purpose of a facing operation?

What is the outcome of a taper turning operation?

What is the outcome of a taper turning operation?

In straight turning operations, what movement does the tool make?

In straight turning operations, what movement does the tool make?

Which statement about straight turning is incorrect?

Which statement about straight turning is incorrect?

What is a key characteristic of taper turning operations?

What is a key characteristic of taper turning operations?

Why is tool positioning significant in lathe operations?

Why is tool positioning significant in lathe operations?

Which of the following is NOT a factor to consider when selecting cutting tools for lathe operations?

Which of the following is NOT a factor to consider when selecting cutting tools for lathe operations?

What defines the feed rate in lathe operations?

What defines the feed rate in lathe operations?

What is the initial adjustment performed on the tool before engaging with the workpiece?

What is the initial adjustment performed on the tool before engaging with the workpiece?

When should you adjust the speed of the lathe during the operation?

When should you adjust the speed of the lathe during the operation?

What is the purpose of making a roughing cut?

What is the purpose of making a roughing cut?

If the compound is set at 30 degrees, how much will the tool advance for each division turned?

If the compound is set at 30 degrees, how much will the tool advance for each division turned?

What happens during the return pass after reaching the center of the workpiece?

What happens during the return pass after reaching the center of the workpiece?

What measurement corresponds to advancing the tool by.010 inches?

What measurement corresponds to advancing the tool by.010 inches?

Why is it critical to start with the tool just touching the workpiece?

Why is it critical to start with the tool just touching the workpiece?

What role does trigonometry play in adjusting the tool's advancement with the compound crank?

What role does trigonometry play in adjusting the tool's advancement with the compound crank?

Flashcards are hidden until you start studying

Study Notes

Lathe Machine Operations Module Overview

- Competency-based assessment for lathe machine operations with a scoring rubric.

- Competency scores range from 1-10, indicating levels from "Not Competent" to "Very Much Competent."

Safety Guidelines for Lathe Operation

- Use brushes or compressed air for cleaning chips and coolant, avoiding use of hands.

- Keep hands clear of rotating parts to prevent injury.

- Tie back long hair and remove loose clothing and jewelry.

- Do not operate under the influence of alcohol or drugs.

- Familiarize with machine controls, including emergency stop buttons.

- Seek training from a qualified individual if inexperienced.

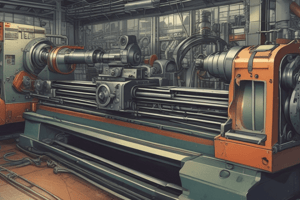

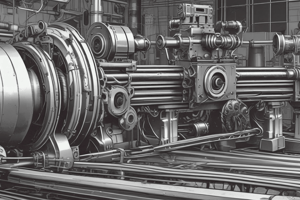

Lathe Machine Functionality

- Primary function: Shaping and cutting materials, particularly metals.

- Key components: Chuck (holds workpiece), spindle (rotates workpiece), tool post (adjusts tool position), apron (supports tool post).

Machining Operations

- Types of operations:

- Facing: Creating a flat surface at the end of a workpiece.

- Straight Turning: Reducing the diameter of the workpiece parallel to its axis.

- Taper Turning: Producing a conical shape by gradually changing the diameter.

Speed and Feed Selection

- Cutting Speed (S): Speed of material removal; calculated using formula S = (π * D * N).

- Feed Rate (F): Distance the tool advances per workpiece revolution; calculated as F = N * f, where f is the feed per revolution.

Steps for Speed and Feed Computation

- Measure workpiece or tool diameter (D).

- Obtain recommended cutting speeds from reference materials.

- Calculate cutting speed (S) using the appropriate formula.

- Select feed per revolution (f) based on material and tool characteristics.

- Determine rotational speed of lathe spindle (N) in RPM.

Machining Process Guidelines

- Perform initial adjustments to tool position and height using micrometers or dial indicators.

- Begin with cautious machining, monitoring the cutting process for effectiveness.

- Roughing cuts involve advancing the tool and may require trigonometric calculations for exact movements based on angles.

- Cutting may occur on both forward and return passes, affecting material removal efficiency.

Learning Objectives

- Define basic lathe operations and their significance in machining.

- Differentiate between operations like facing, turning, and others.

- Select appropriate cutting tools based on various parameters.

- Understand tool positioning and angles for desired surface finishes.

- Apply correct feed rates and cutting speeds according to material characteristics.

Test Yourself

- True/False assessments to evaluate understanding of lathe operations and safety measures are included.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.