Podcast

Questions and Answers

In cases where a fire and rescue apparatus requires external maintenance, what post-service verification would MOST comprehensively ensure seamless operational continuity upon the unit's return to service?

In cases where a fire and rescue apparatus requires external maintenance, what post-service verification would MOST comprehensively ensure seamless operational continuity upon the unit's return to service?

- Conducting a full operational readiness test encompassing all critical systems, alongside a thorough inventory of equipment and consumables replaced or serviced. (correct)

- Confirming completion of the specified maintenance tasks via visual confirmation and reviewing of service checklists.

- Consulting with maintenance technicians to gain insights on nuances observed during service procedures.

- Cross-referencing the maintenance report against the original work order to ascertain alignment of services rendered.

Under what specific circumstances is the application of silicone-based lubricants generally discouraged or contraindicated in fire and rescue apparatus maintenance, particularly when considering delicate or sensitive systems?

Under what specific circumstances is the application of silicone-based lubricants generally discouraged or contraindicated in fire and rescue apparatus maintenance, particularly when considering delicate or sensitive systems?

- During preventative maintenance on composite materials where the solvents can cause break-down of the material.

- When lubricating components exposed to extremely high temperatures or pressures that may accelerate silicone compound breakdown.

- When addressing external moving parts not subject to direct environmental contamination.

- For all pneumatic systems and oxygen-handling equipment, where the non-inert properties of silicone can catalyze detrimental interactions. (correct)

Among the various inspections of a centrifugal fire pump as a component of weekly preventative maintenance, what represents the most critical procedure for ensuring operational readiness when drafting from a static water source?

Among the various inspections of a centrifugal fire pump as a component of weekly preventative maintenance, what represents the most critical procedure for ensuring operational readiness when drafting from a static water source?

- Verifying the presence and cleanliness of the steamer intake strainers without testing the valve's operation.

- Applying non-specified lubricants to aid in priming.

- Verifying the integrity and proper seating of all intake valve gaskets related to the pump's suction capability before any operation. (correct)

- Backflushing the pump to eliminate any sedimentary accumulation from the impeller housing without priming the pump.

When evaluating the operational readiness of fire hose couplings, particularly on hard suction hoses, what specific maintenance intervention should be prioritized to mitigate the effects of galvanic corrosion and ensure reliable thread engagement?

When evaluating the operational readiness of fire hose couplings, particularly on hard suction hoses, what specific maintenance intervention should be prioritized to mitigate the effects of galvanic corrosion and ensure reliable thread engagement?

Considering the nuances of fire apparatus chain saw maintenance, which aspect is LEAST crucial for ensuring both optimal performance and longevity of the tool?

Considering the nuances of fire apparatus chain saw maintenance, which aspect is LEAST crucial for ensuring both optimal performance and longevity of the tool?

In the context of portable fire extinguisher inspections, what precise parameter is indicated by the inspection label affixed to the extinguisher body, and how does it influence operational deployment decisions?

In the context of portable fire extinguisher inspections, what precise parameter is indicated by the inspection label affixed to the extinguisher body, and how does it influence operational deployment decisions?

When conducting maintenance on rescue tools of the eDRAULIC type, what is the PRIMARY justification for storing hydraulic spreaders with a minimal gap maintained between the tips?

When conducting maintenance on rescue tools of the eDRAULIC type, what is the PRIMARY justification for storing hydraulic spreaders with a minimal gap maintained between the tips?

Given the operational demands placed on fire service equipment, which of the following statements offers the MOST comprehensive guideline for lubricant application during routine maintenance?

Given the operational demands placed on fire service equipment, which of the following statements offers the MOST comprehensive guideline for lubricant application during routine maintenance?

What is the MOST probable consequence of neglecting to regularly exercise rarely-used valves on a fire apparatus?

What is the MOST probable consequence of neglecting to regularly exercise rarely-used valves on a fire apparatus?

Following scheduled or unscheduled maintenance, or extensive repairs to a fire engine, what specific operational check offers the greatest degree of assurance that the onboard pump is functioning according to the established performance parameters?

Following scheduled or unscheduled maintenance, or extensive repairs to a fire engine, what specific operational check offers the greatest degree of assurance that the onboard pump is functioning according to the established performance parameters?

In the context of pre-incident planning for multi-story structure fires, what is the most critical consideration when positioning the initial arriving engine company apparatus to optimize operational effectiveness and safety?

In the context of pre-incident planning for multi-story structure fires, what is the most critical consideration when positioning the initial arriving engine company apparatus to optimize operational effectiveness and safety?

At a motor vehicle accident on a busy highway, during the hours of darkness, with on-coming traffic, state the most important consideration when positioning the engine.

At a motor vehicle accident on a busy highway, during the hours of darkness, with on-coming traffic, state the most important consideration when positioning the engine.

At an incident where a single-family residence is fully involved in fire, where should the first arriving engine company position the apparatus, and why?

At an incident where a single-family residence is fully involved in fire, where should the first arriving engine company position the apparatus, and why?

Select the most appropriate statement regarding the function of 'diesel exhaust fluid' in fire and rescue apparatus.

Select the most appropriate statement regarding the function of 'diesel exhaust fluid' in fire and rescue apparatus.

Which of these options is NOT an example of when TSF (Tactical Support Facility) should be contacted

Which of these options is NOT an example of when TSF (Tactical Support Facility) should be contacted

Flashcards

Daily Apparatus Inspection

Daily Apparatus Inspection

Inspection performed at the beginning of each shift to identify any discrepancies in the apparatus.

Who is responsible?

Who is responsible?

The engineer (or operator) and the company officer.

When to perform a thorough inspection?

When to perform a thorough inspection?

Every Monday, in addition to the daily inspection.

Hand tool maintenance

Hand tool maintenance

Signup and view all the flashcards

Why shut off fuel supply to portable gas motors?

Why shut off fuel supply to portable gas motors?

Signup and view all the flashcards

Engine placement for Roadway Incidents

Engine placement for Roadway Incidents

Signup and view all the flashcards

Engine placement for single story structure

Engine placement for single story structure

Signup and view all the flashcards

Engine placement for multi-story fire

Engine placement for multi-story fire

Signup and view all the flashcards

Study Notes

- The document provides information for Jacksonville Fire and Rescue Department Engine Company Engineers.

- The document covers topics from maintenance to tactical considerations at incident scenes.

- The document's seventh edition was revised November 27, 2024.

- The copyright is held by JFRD (Jacksonville Fire and Rescue Department) and was established in 2015.

- Reproduction of the work requires written permission from JFRD.

- Contact 904-997-4920 for JFRD Training Division.

- Contact 904-255-3280 for JFRD Headquarters.

Historical Information

- Jacksonville’s second volunteer company, The Mechanics Steam Engine Company, formed January 2nd, 1870.

- The Mechanics Steam Engine Company purchased Florida’s first steam engine.

- The first steam engine could throw a stream of water 200 feet at 250 gallons per minute.

- The Mechanics firehouse was on Adams Street between Main and Laura Streets.

- JFRD's Fire Chief Miles R. Bowers wrote a training book adopted by the Florida State Fire College, influencing statewide training.

Preventive Maintenance

- Fire and Rescue apparatus must be continuously maintained ready to respond and protect the crew.

- Crucial inspections and preventive maintenance is required for apparatus readiness.

- All company members should assist in care, cleaning, and upkeep as assigned.

- A daily inspection must be performed at the beginning of each shift

- Record each discrepancy in the Daily Apparatus Check Off, located in the JFRD Portal under Tactical Support tab, then Daily Apparatus Management.

- Report safety/operational concerns with an appropriate logbook entry and notify the company officer immediately

- Check the status of equipment used during the shift and returned to full operational status ASAP.

- Contact the Tactical Support Facility (TSF) for maintenance related issues.

- Report any JFRD equipment that has been lost, found, stolen, or damaged immediately report to the company officer.

- Diesel exhaust is carcinogenic; all measures to avoid exposure must be taken according to NFPA and NIOSH.

Daily Engine Inspection

- Conduct a brief conference with the off-going engineer.

- Ensure proper fluid levels including motor oil, transmission fluid, coolant, power steering fluid, and diesel exhaust fluid (DEF).

- Record any added fluids on Daily Apparatus Report.

- The engineer is the ONLY person allowed to place fluids into their respective units and the company officer must verify that the proper fluids are being added.

- Improper placement of fluids into the apparatus has caused damage, costly repairs, and could cause the apparatus to malfunction on an emergency scene putting people at risk.

- All fluids must be installed with the proper type and grade.

- Contact TSF with fluid questions.

- Booster tanks and foam tank levels must be checked by visual observation and compared to gauges for accuracy

- Ensure air brake pressure is above 100 PSI for both front and rear, and ensure they operate properly.

- Check tires and wheels for tire pressure, lug nuts, axle seals, and tread depth.

- Minimum tire tread depth is 4/32" or when tread wear indicators are even with the tire tread.

- Ensure all seat belts operate and adjust properly.

- Ensure wipers operate properly.

- With the motor running check all running lights (including brake and backup lights), visual and audible warning devices, and scene lighting.

- Once the motor is started, it must run until it reaches normal operating temperature.

- Verify normal readings on all cab-mounted gauges.

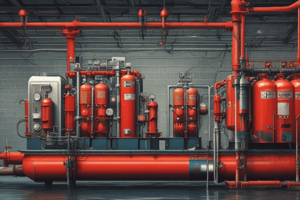

Pump Inspection

- Verify pressure on the master discharge gauge with the pump engaged and TANK-TO-PUMP valve open.

- Operate primer until water is discharged.

- Ensure proper operation of the governor in both PSI and RPM modes.

- Ensure proper operation of the transfer valve if the unit is equipped.

- Discharge water from at least one discharge opening.

- Open and close each 5" intake valve then remove the cap to drain.

- Disengage the pump and then open/close each manual valve smoothly.

- Open and close all bleeders.

- Open the PUMP DRAIN valve briefly to flush sediment from the pump's lowest level.

- Tilt the cab and inspect all drive belts for tightness and wear.

- Check batteries for leaks and tight connections, securing loose cab equipment before tilting.

- Never place any part of the body under the cab while raising or lowering; when fully open, ensure the cab tilt lock is in place.

- Do not lower the cab and allow it to rest on the strut, as this places undue stress on the strut assembly.

- View the underside of the engine for pump or tank leaks, checking motor, transmission, pump transfer case, and drivetrain for fluid leaks.

- Set air brakes and not climb under apparatus while motor is running.

- Sweep dirt and debris from the cab and wipe down surfaces as needed.

- Inspect apparatus exterior, noting any new body damage.

Daily Equipment Inspection

- Defibrillator batteries should be changed, and proper operation ensured, along with immediate access to associated equipment.

- Portable oxygen tank pressure should be greater than 1000 PSI, and oxygen delivery adjuncts must be properly stocked.

- Medical jump bag and other EMS equipment (backboard, c-collars, ALS equipment) must be fully stocked and ready for immediate use.

- Connect air chisel to air bottle and ensure proper operation with bottle pressure above 4000 PSI, avoiding triggering unless the chisel head is in contact with a solid material.

- Inspect SCBA and spare bottle in accordance with SOG 421.

- Pre-connected hoselines and supply hose shall be stacked properly, nozzles properly set and free of debris.

- Verify compartment door operation and ensure ready equipment is in place.

- Chainsaw chains should be sharp and adjusted, fuel and oil levels full, and verified operation with motor oil used for the bar lubricant.

- Ensure each portable radio has a fully charged battery.

- Ensure proper operation of eDRAULIC tools, if equipped, and store hydraulic spreaders with a ½” gap between the tips.

- Check oil and coolant levels of the generator, if equipped, and run until fully warmed up (approximately 5 minutes).

- Shut off fuel supply to portable gas motors and run until the motor stalls to clear fuel lines and prevent damage from gasoline additives.

- Maintain an adequate supply of gasoline and gas/oil mix, adding fuel stabilizer to newly acquired gas and rotating older gas for lawn equipment use.

Weekly Inspection and Maintenance

- Monday, a thorough inspection is performed in addition to the daily inspection.

- Use judgment to maintain engine and pump, with the company captain establishing a maintenance schedule.

- The apparatus cab shall be cleaned thoroughly, ensure all maps, books and keys are accounted for.

- Wipe down interior surfaces, and glass and mirrors.

- Clean the thermal imaging camera and verify proper charging.

- Clean the exterior of the apparatus and apply wax monthly or in accordance with the schedule.

- all compartments shall be emptied and the shelves should be cleaned.

- To clean roll-up door tracks remove dirt and old lubricant, and apply silicone spray to apply light oil to both sides of the door hinges.

- Operate the door several times and remove excess oil.

- Remove each pump cap, elbow and wye, and clean all threads on the pump appliance and apply grease as needed.

- Inspect the gaskets and replace if necessary along with the ensuring strainers are present in 2-½” intakes.

- Operate all pump valves while noting resistance or improper operation and clean or lubricate will needed.

- Remove and clean the intake valve, inspect internal casing for rust or sediment build-up, operation of the valve.

- To clean and lubricate the Storz connection gasket, use internal threads and bleeder valve.

- If the Swivel don't move freely, apply soapy water.

Weekly Equipment Checks

- Clean and lubricate all hand tools and moving parts, check axe heads for tightness, and inspect handles for damage.

- Use soap and water to clean then dry thoroughly.

- Apply light oil to steel surfaces and moving parts, and linseed oil to wood handles as needed.

- Clean ladders with soapy water and manipulate all moving parts.

- Inspect heat indicators for discoloration and physical damage.

- Sparingly lubricate roof hooks with light oil and rinse dirt/debris from ladder compartments.

- Clean nozzles with soapy water and a soft brush, immersing in warm soapy water and operating all moving parts, avoiding lubricants.

- Exercise hard suction hose couplings and apply warm soapy water to rotate swivels if frozen or stiff, cleaning debris from hard suction hose compartments.

- Thoroughly inspect and clean chainsaws, inspect, remove, and clean the air filter if indicated, as well as the chain assembly and chain drive.

- Remove debris from hard-to-reach areas with air pressure, reinstall chain with proper tension.

- Clean air tools with soapy water and dry thoroughly, lubricating each blade with light oil and applying 5 drops of air tool oil into the blade end and operate.

- Charge batteries on all battery-powered tools, ensure all bits and blades are accounted for, and operate each piece of equipment.

- Inspect SCBA buddy breathing hoses, ensure quick-connect couplings are free of debris, and clean SCBA backpacks as needed.

- Check hydrostatic dates on oxygen and SCBA bottles, in accordance with SOG 421.

- Inspect portable extinguishers for proper charge and annual inspection date, using the inspection label to confirm the last inspection date.

- Rope shall be inspected in accordance with SOG 419.

- Winch (if equipped) should be installed at each connecting point to ensure proper operation of winch and power connections.

- Clean high-lift jacks, chains, and come-alongs with appropriate methods, checking for damage, corrosion, wear, or broken strands.

Recommended Lubricants and Additives

- Use lubricants sparingly, as excess oil or grease can attract dirt and compromise operation.

- Light oil refers to Liquid Wrench, WD-40, or similar water-displacing lubricating oil, typically in an aerosol can.

- Air Tool Oil – supplied with the air chisel in a small squeeze bottle.

- Two-Cycle Oil – added to gasoline to lubricate two-cycle engines

- Silicone Spray – used on roll-up door tracks and slide out compartment trays, ensuring minimal residue.

- Remove dirt prior to applying silicone on other moving parts.

- Graphite is recommended to ease the movement of pump valve handles, applied to the remote control handle shaft and mechanism after removing dirt.

- Use only "food grade” machinery grease grease, applied to appliance and pump threads as needed.

- Add fuel Stabilizer to all newly acquired gasoline according to the label.

- Diesel exhaust fluid (DEF) is used in some engines to reduce nitrogen oxide emissions.

Scheduled and Unscheduled Maintenance

- Engine maintenance may require service at TSF, Fleet Management, or a private repair facility

- Regardless of the source, the following procedures shall be performed following maintenance to ensure proper operation of critical components.

- If service requires the engine to be out of service for 24 hours or spans two shifts, immediately perform a complete daily inspection before swapping equipment and returning to service

- Focus on what was worked on to ensure it is proper.

- If service was performed on the engine and returned on the same day then the following checks must be completed before returning it to service:

- Visual check of booster tank level.

- Verify proper operations of the pump and governor operating properly (in both modes)

- Verify that the break pressures are proper working conditions

- Verify that all the equipment is accounted for

Engine Positioning at Incident Scenes

- Recommended engine spotting/placement is consistent with SOGs 402 and 406.

EMS Responses

- At a single-family residence, prioritizes the location of the rescue unit and stretcher access, considering patient safety during loading.

- Use the engine as a barrier to protect the patient loading area on busy streets.

- Due to the limited access of apartments the engine may need to be well removed from the location.

- Park outside, leaving access for the rescue unit in complexes

Roadway Incidents

- Patient/responder safety is paramount for engine positioning.

- Use the engine as a barrier to block traffic, allowing room for manipulation of the patient and stretcher, hose advancement.

- Exhaust pipe should be taken into consideration when treating patients.

- Spot uphill and upwind of spills or leaks.

- Use police to ensure scene safety.

- Placing the truck needs to be determined if extrication is required.

- Turn off headlights to improve vision in apparatus facing traffic at night

- If deploying scene lighting, do not create a hazard.

Structure Fires

- Initial arriving Engine and Ladders should be placed in front on the structure in most cases.

- Position the attack lines where it leaves room in front of the other company.

- Engine placement is the same for Multi story Structures as singular structures.

- Engine should be placed to leave building corners open, permitting the ladder company to reach two-sides.

Tactical and Safety Considerations

- Refrain from parking beneath power lines

- Refrain from moving too close to involved structures to reduce the damage to the trucks.

- Provide room to deploy the hose lines and keep them clear of the exhaust.

- Do not leave any rear apparatus obstructed with little to no ground ladder and no access.

- Contact TSF prior to attempting removal of any engine that has become stuck.

- Refrain from driving on any private driveways or on private bridges besides emergency response.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.