Podcast

Questions and Answers

What are control systems designed to do?

What are control systems designed to do?

Regulate and monitor industrial processes to achieve precise outputs.

Which of the following are common control system types? (Select all that apply)

Which of the following are common control system types? (Select all that apply)

- Proportional-integral-derivative (PID) controllers (correct)

- Industrial robots

- Sensors

- Programmable logic controllers (PLCs) (correct)

What is a benefit of automation?

What is a benefit of automation?

- Increased human error

- Enhanced productivity (correct)

- Higher labor costs

- Decreased product quality

Data analytics is not important in industrial automation.

Data analytics is not important in industrial automation.

What role does IoT play in manufacturing?

What role does IoT play in manufacturing?

Which practices are enabled by data analysis in automation? (Select all that apply)

Which practices are enabled by data analysis in automation? (Select all that apply)

What does process optimization aim to improve?

What does process optimization aim to improve?

Security concerns are unimportant when implementing IoT in manufacturing.

Security concerns are unimportant when implementing IoT in manufacturing.

Process optimization involves detailed analysis to streamline processes, reduce waste, and enhance overall performance in terms of ______.

Process optimization involves detailed analysis to streamline processes, reduce waste, and enhance overall performance in terms of ______.

Which of the following are key characteristics of control systems? (Select all that apply)

Which of the following are key characteristics of control systems? (Select all that apply)

Control systems utilize a feedback mechanism to adjust its actions.

Control systems utilize a feedback mechanism to adjust its actions.

What type of controllers are widely used in industrial control systems for their adaptability?

What type of controllers are widely used in industrial control systems for their adaptability?

The measured value of a controlled variable is known as the ______.

The measured value of a controlled variable is known as the ______.

Name one example of a sensor used in control systems.

Name one example of a sensor used in control systems.

What function does an actuator serve in a control system?

What function does an actuator serve in a control system?

Flashcards

Industrial Automation

Industrial Automation

Using technology to automate processes in industries, increasing efficiency and reducing human error.

Control Systems

Control Systems

Systems that regulate industrial processes to meet precise output goals using feedback loops.

Data Analytics in Automation

Data Analytics in Automation

Using data from automation systems for valuable insights, enabling better decision-making.

IoT in Manufacturing

IoT in Manufacturing

Signup and view all the flashcards

Process Optimization

Process Optimization

Signup and view all the flashcards

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs)

Signup and view all the flashcards

Predictive maintenance

Predictive maintenance

Signup and view all the flashcards

Feedback Loops

Feedback Loops

Signup and view all the flashcards

Process Automation

Process Automation

Signup and view all the flashcards

Robotic Automation

Robotic Automation

Signup and view all the flashcards

Industrial Automation

Industrial Automation

Signup and view all the flashcards

Control Systems

Control Systems

Signup and view all the flashcards

PID Controllers

PID Controllers

Signup and view all the flashcards

PLC (Programmable Logic Controller)

PLC (Programmable Logic Controller)

Signup and view all the flashcards

Feedback

Feedback

Signup and view all the flashcards

Set Point

Set Point

Signup and view all the flashcards

Process Variable

Process Variable

Signup and view all the flashcards

Automation Levels

Automation Levels

Signup and view all the flashcards

Actuator

Actuator

Signup and view all the flashcards

Sensor

Sensor

Signup and view all the flashcards

Study Notes

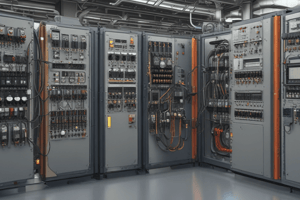

Industrial Automation

- Industrial automation encompasses technologies and systems designed to automate various processes and tasks within industrial settings.

- Key components include programmable logic controllers (PLCs), sensors, actuators, and industrial robots.

- Automation aims to increase efficiency, reduce human error, and improve overall output.

- Benefits of automation include enhanced productivity, reduced labor costs, and improved product quality.

- Types of automation systems include robotic automation, process automation, and discrete automation.

- Automation can be applied across various industries including manufacturing, automotive, and logistics.

Control Systems

- Control systems regulate and monitor industrial processes to achieve precise outputs.

- They utilize feedback loops to measure deviations from desired conditions and adjust accordingly.

- Common control system types include proportional-integral-derivative (PID) controllers and programmable logic controllers (PLCs).

- Control algorithms are used to maintain system stability and performance.

- Control systems can adjust variables like temperature, pressure, and flow rate in industrial processes, optimising output and limiting waste.

- They are crucial for maintaining safety and reliability in high-risk industrial environments.

Data Analytics in Automation

- Data analytics plays a vital role in extracting valuable insights from data generated in industrial automation systems.

- This data includes sensor readings, machine performance metrics, and process parameters, among others.

- Data analysis techniques, such as machine learning, artificial intelligence, and statistical analysis, can be applied to optimise process parameters.

- Data analysis enables predictive maintenance, process optimization, and improved decision-making.

- Predictive maintenance can prevent equipment failures, reducing downtime and unexpected costs.

- Real-time data analysis facilitates quick problem identification and resolution.

- Automation systems generate considerable amounts of data which need efficient storage, processing, and analysis to extract meaningful insights.

IoT in Manufacturing

- The Internet of Things (IoT) connects various industrial devices and machines, enabling real-time data exchange and analysis.

- Connected devices and sensors monitor different aspects of manufacturing processes (e.g., temperature, pressure, vibration).

- IoT enables remote monitoring and control of manufacturing equipment, enhancing process efficiency.

- Data from connected devices is analysed to identify and address operational inefficiencies.

- IoT in manufacturing enables predictive maintenance.

- Real-time data provides insights, allowing proactive responses to process problems and equipment failures.

- Security concerns associated with data transmission and potential vulnerabilities in connected systems are crucial considerations.

Process Optimization

- Process optimization strives to improve efficiency and productivity in industrial operations.

- This can involve refining existing processes or developing entirely new ones.

- A crucial aspect of process optimization is data analysis of outputs, identifying bottlenecks or inefficiencies.

- Optimization considers factors like resource utilization, material handling, and energy consumption.

- Process optimization involves detailed analysis to streamline processes, reduce waste, and enhance overall performance.

- Statistical process control methods can help identify and remove sources of variation, leading to improved quality.

- Process optimization leads to better utilisation of raw materials and reduced operational costs.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz covers key concepts in industrial automation and control systems. It explores the components, benefits, and types of automation systems, as well as the functioning of control systems that regulate industrial processes. Perfect for students looking to deepen their understanding of these vital technologies.