Podcast

Questions and Answers

What are the three stages of heat treatment?

What are the three stages of heat treatment?

- Annealing, Tempering, Quenching

- Heating, Normalizing, Annealing

- Cooling, Soaking, Hardening

- Heating, Soaking, Cooling (correct)

Annealing is a heat treatment process used to soften metals.

Annealing is a heat treatment process used to soften metals.

True (A)

What is the purpose of Normalizing in heat treatment?

What is the purpose of Normalizing in heat treatment?

To remove structural irregularities or impurities and defects from the metal, improve ductility, reduce hardness, increase toughness, relieve internal stresses, and improve machinability.

Case hardening is a type of hardening process where the outside of the material is hardened, while the inside remains __________.

Case hardening is a type of hardening process where the outside of the material is hardened, while the inside remains __________.

Match the following case hardening methods with their descriptions:

Match the following case hardening methods with their descriptions:

What is the basic purpose of tempering?

What is the basic purpose of tempering?

Which type of tempering is known for producing metallurgical structure called bainite?

Which type of tempering is known for producing metallurgical structure called bainite?

Brine cools slower than air, water, and oil.

Brine cools slower than air, water, and oil.

_______ is a popular quenching media used to cool metals for quenching.

_______ is a popular quenching media used to cool metals for quenching.

Match the following metal cooling media with their cooling rates:

Match the following metal cooling media with their cooling rates:

What does TTT diagram stand for?

What does TTT diagram stand for?

Flashcards are hidden until you start studying

Study Notes

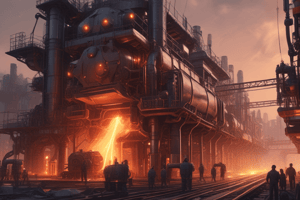

Heat Treatment Process

- Definition: Heat treatment is the process of heating metal without letting it reach its molten stage, and then cooling the metal in a controlled way to select desired mechanical properties.

- Purpose: To make the metal stronger or more malleable, more resistant to abrasion, or more ductile.

Stages of Heat Treatment

- Heating Stage: Ensure uniform temperature, heat slowly, and choose heating rate according to metal conductivity, condition, size, and cross-section.

- Soaking Stage: Keep metal at desired temperature until desired internal structure takes shape.

- Cooling Stage: Cool metal back to room temperature using a cooling medium (gas, liquid, solid, or a combination).

History of Heat Treatment

- 6000 BC: Humans learned to recover metal from ores.

- 1200 BC: Iron Age began, and metalworking advances allowed for new technology and machinery.

Properties of Metals Influenced by Heat Treatment

- Mechanical Properties: ductility, corrosion resistance, hardness, machinability

Types of Heat Treatment

Annealing

- Definition: Process that changes physical and sometimes chemical properties of a material.

- Process: Heat metal to appropriate temperature, hold, and then slowly cool.

- Purpose: Soften metal, increase ductility and machinability, and reduce hardness.

- Types of Annealing: full annealing, partial annealing, subcritical annealing.

Normalizing

- Definition: Process used to relieve internal stresses caused by processes like welding, casting, or quenching.

- Process: Heat material to pre-decided elevated temperature, hold, and then cool freely in air.

- Purpose: Remove structural irregularities, improve ductility, reduce hardness, and relieve internal stresses.

Hardening

- Definition: Process that improves mechanical properties and increases hardness.

- Process: Use tempering or stress relieving to improve dimensional stability and toughness.

- Case Hardening: Harden outer layer of material while keeping inside soft.

- Methods of Case Hardening: carburizing, nitriding, cyaniding.

Tempering

- Definition: Process that develops required combination of hardness, strength, and toughness.

- Process: Reheat steel to relatively low temperature to precipitate and spheroidize carbides.

- Purpose: Reduce brittleness and increase strength of metal.

Quenching

- Definition: Process that rapidly cools heated metal to achieve desired properties.

- Media for Quenching: air, oil, water, brine.

Time-Temperature-Transformation (TTT) Diagram

- Definition: Plot of temperature against log of time for a steel alloy of definite composition.

- Purpose: Determine when transformation begins and ends for an isothermal heat treatment.

Continuous Cooling Diagram (CTT)

- Definition: Diagram used to represent phase changes in material as it is cooled at different rates.

- Purpose: Determine phase changes in steel during continuous cooling.

Benefits of Heat-Treating Metals

- Increased strength and ductility

- Increased resistance to corrosion

- Increased malleability and workability during manufacturing

- Improved electrical and magnetic properties

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.