Podcast

Questions and Answers

What is the primary purpose of adjusting the blade tension in a hacksaw?

What is the primary purpose of adjusting the blade tension in a hacksaw?

- To ensure a curved cut

- To reduce the pressure on the handle

- To allow the blade to be mounted at different angles

- To ensure a straight cut and lengthen the life of the blade (correct)

What is the typical length of the blades used in a junior hacksaw?

What is the typical length of the blades used in a junior hacksaw?

- 6 in. (correct)

- 14 in.

- 6.25 in.

- 32 in.

What type of handles are commonly used in hacksaws?

What type of handles are commonly used in hacksaws?

- Straight handle and cylindrical handle

- Pistol grip and straight handle (correct)

- Pistol grip and curved handle

- Pistol grip and T-handle

What is the purpose of releasing the blade tension after use in a hacksaw?

What is the purpose of releasing the blade tension after use in a hacksaw?

What is the characteristic of the blades used in a coping saw?

What is the characteristic of the blades used in a coping saw?

What is the primary difference between a junior hacksaw and a coping saw?

What is the primary difference between a junior hacksaw and a coping saw?

What is the primary purpose of piercing saws?

What is the primary purpose of piercing saws?

What is unique about tension files compared to other saws?

What is unique about tension files compared to other saws?

What determines the choice of hacksaw blade?

What determines the choice of hacksaw blade?

What type of metals require coarse-pitch blades?

What type of metals require coarse-pitch blades?

Why must fine blades be used for tubing and thin metals?

Why must fine blades be used for tubing and thin metals?

What is the typical length of piercing saw blades?

What is the typical length of piercing saw blades?

What is the primary factor that determines the feed rate of a drill?

What is the primary factor that determines the feed rate of a drill?

What is the formula to convert cutting speed into rpm?

What is the formula to convert cutting speed into rpm?

What is the purpose of the centre punch mark in drilling small holes?

What is the purpose of the centre punch mark in drilling small holes?

What is the relationship between the hardness of the material being cut and the cutting speed?

What is the relationship between the hardness of the material being cut and the cutting speed?

What is the feed rate for drilling a 3/8" hole in aluminium?

What is the feed rate for drilling a 3/8" hole in aluminium?

What is the rpm for drilling a 3/8" hole in titanium?

What is the rpm for drilling a 3/8" hole in titanium?

What is the primary limitation of using a standard countersink bit for countersinking holes?

What is the primary limitation of using a standard countersink bit for countersinking holes?

What is the main advantage of using a stop countersink tool?

What is the main advantage of using a stop countersink tool?

What is the purpose of changing the pilots in a stop countersink tool?

What is the purpose of changing the pilots in a stop countersink tool?

What is the primary difference between countersinking and press countersinking?

What is the primary difference between countersinking and press countersinking?

What is the characteristic of the hole formed by the coin dimpling method?

What is the characteristic of the hole formed by the coin dimpling method?

What is the advantage of using coin dimpling over radius dimpling?

What is the advantage of using coin dimpling over radius dimpling?

What is the first step in cutting external threads using a circular die?

What is the first step in cutting external threads using a circular die?

What is the purpose of slightly tapering the rod end?

What is the purpose of slightly tapering the rod end?

What is the primary purpose of die nuts?

What is the primary purpose of die nuts?

What is the correct sequence to re-tighten the screws in the stock?

What is the correct sequence to re-tighten the screws in the stock?

What is the final step in cutting external threads using a circular die?

What is the final step in cutting external threads using a circular die?

What type of steel are die nuts typically made of?

What type of steel are die nuts typically made of?

Flashcards are hidden until you start studying

Study Notes

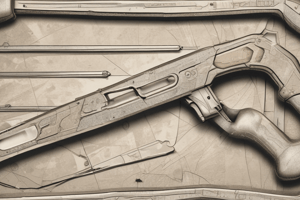

Hacksaws

- Hacksaw frames are adjustable in length to accommodate blades of different lengths.

- Rectangular section steel tube is often used to make hacksaw frames.

- Handles can be of the pistol grip type or straight handled like a file.

- Blade tension is adjusted by turning the wingnut at one of the blade attachment points.

- Blade must be under tension when the saw is in use to ensure a straight cut and lengthen the life of the blade.

- Attachment points are of square section and mounted in square holes, allowing the blade to be mounted in line with the frame or at right angles to it.

Types of Hacksaws

- Junior hacksaw: used for general light work where a standard hacksaw is too clumsy, with 6-in. blades with pinned ends and flexible, 6 in. × 32 TPI blades.

- Coping saw: used for shaping soft materials like wood, with pinned blades 6.25 in. long, with 14 TPI.

- Piercing saw: used for fine sawing of intricate shapes in thin sheet, with 5 in. long blades with TPI from 32 to 80, and serrated and hardened clamps ensuring a firm grip on the blades.

Tension Files

- Tension files (e.g., Abrafiles) are made from specially heat-treated flexible steel wire.

- They do not clog and will cut in any direction, making them very useful for cutting intricate shapes or irregular holes in thin metal.

- Links enable the blades to be used in a standard hacksaw frame.

- Blades are available in three grades: fine, medium, and coarse, and are 8 in. long.

Hacksaw Blades

- The choice of blade depends on the type of material to be cut, with soft metals (e.g., brass, aluminum) requiring coarse-pitch blades and hard metals (e.g., iron and steel) requiring fine-pitch blades.

- The shape and thickness of the material must also be considered, with at least three teeth must be in contact with the material at any time.

Drill Speed and Feed Rates

- Drill speed and feed rates depend on the material being cut, the size of the drill, and the type of drill.

- The harder the material being cut and the larger the drill, the lower the cutting speed.

- The harder the drill material, the higher the cutting speed.

Centre Punching and Centre Drilling

- Centre punching is used to guide the drill until it is established in the metal.

- The standard countersink bit can be used for small jobs, but is not suitable for large jobs or pressurized skins.

- The stop countersink tool can be used for large jobs, providing a consistent depth and accuracy.

Press Countersinking

- Press countersinking (or dimpling) is used where the aircraft skin is too thin to countersink.

- It forms the edges of the hole to accommodate the head of the rivet using a set of dimpling dies.

- There are two methods: coin dimpling and radius dimpling.

Cutting External Threads

- Cutting external threads using a circular die requires securing the work in the vice, tapering the rod end, and slackening the two outer screws in the stock.

- The die and stock must be placed squarely on the rod, and the thread cut using the same technique as for taps.

Die Nuts

- Die nuts are made of high-quality chromium tool steel to exacting specifications.

- They are similar in shape to normal hexagon or square nuts, but are not intended for cutting threads.

- They are used for easing or restoring damaged threads on studs or bolts, and are turned by a suitably sized spanner.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.