Podcast

Questions and Answers

Which of the following is NOT a key step in the Additive Manufacturing process sequence?

Which of the following is NOT a key step in the Additive Manufacturing process sequence?

- Material extraction (correct)

- Transfer and manipulation of STL file

- Post-processing of part

- Conceptualization and CAD

The STL file format is used for different AM machine types.

The STL file format is used for different AM machine types.

True (A)

What does STL stand for in the context of Additive Manufacturing?

What does STL stand for in the context of Additive Manufacturing?

STereoLithography

The ______ process involves the removal of supports and hollowing out parts to optimize designs for AM.

The ______ process involves the removal of supports and hollowing out parts to optimize designs for AM.

Match the type of AM machine to its characteristic:

Match the type of AM machine to its characteristic:

Which area does NOT typically involve conventional CAD modeling?

Which area does NOT typically involve conventional CAD modeling?

Energy density is a critical factor in metal additive manufacturing.

Energy density is a critical factor in metal additive manufacturing.

Name one operational issue related to materials handling in additive manufacturing.

Name one operational issue related to materials handling in additive manufacturing.

What is one common requirement before building a part?

What is one common requirement before building a part?

It is common for AM machines to setup a single material with no variation in build parameters.

It is common for AM machines to setup a single material with no variation in build parameters.

What do AM machines do after the initial semi-automated stages?

What do AM machines do after the initial semi-automated stages?

Parts produced by AM machines often require significant amount of manual __________ before they are ready for use.

Parts produced by AM machines often require significant amount of manual __________ before they are ready for use.

Match the following actions with their appropriate descriptions:

Match the following actions with their appropriate descriptions:

What may some parts require to ensure quality during the additive manufacturing process?

What may some parts require to ensure quality during the additive manufacturing process?

Once a part is built, it is usually ready for immediate use without any finishing.

Once a part is built, it is usually ready for immediate use without any finishing.

What is a potential unusual requirement for some STL files?

What is a potential unusual requirement for some STL files?

What is the purpose of support structures in additive manufacturing (AM)?

What is the purpose of support structures in additive manufacturing (AM)?

Post-processing stages in AM are usually automated and do not require manual intervention.

Post-processing stages in AM are usually automated and do not require manual intervention.

What are some common methods used in the post-processing stage of AM?

What are some common methods used in the post-processing stage of AM?

AM processes often result in parts that have small voids or ______ trapped inside them.

AM processes often result in parts that have small voids or ______ trapped inside them.

Match the following terms with their descriptions:

Match the following terms with their descriptions:

What can result from mishandling parts during support removal in AM?

What can result from mishandling parts during support removal in AM?

The properties of parts created through additive manufacturing are typically the same in all directions.

The properties of parts created through additive manufacturing are typically the same in all directions.

Some applications may not require ______ performance from many components produced through AM.

Some applications may not require ______ performance from many components produced through AM.

Which of the following statements about future developments in additive manufacturing is accurate?

Which of the following statements about future developments in additive manufacturing is accurate?

Architectural modeling designs are always exact representations of the final product.

Architectural modeling designs are always exact representations of the final product.

What is a key feature of droplet-based systems like the Thermojet process?

What is a key feature of droplet-based systems like the Thermojet process?

In lamination methods, supports are required to hold the sheets in place.

In lamination methods, supports are required to hold the sheets in place.

What is the purpose of optimizing software for additive manufacturing?

What is the purpose of optimizing software for additive manufacturing?

The technology involving the use of __________ scanning is essential for reverse engineering data.

The technology involving the use of __________ scanning is essential for reverse engineering data.

What factors should be considered when working with metal systems compared to polymer systems?

What factors should be considered when working with metal systems compared to polymer systems?

Material handling issues require exposure to ______ and to excess light to be avoided.

Material handling issues require exposure to ______ and to excess light to be avoided.

Match the following technologies or processes with their description:

Match the following technologies or processes with their description:

Match the application areas with their corresponding techniques:

Match the application areas with their corresponding techniques:

Which of the following is NOT an aspect of design for additive manufacturing (AM)?

Which of the following is NOT an aspect of design for additive manufacturing (AM)?

Careful monitoring of machines is necessary due to fragile laser or printer technology.

Careful monitoring of machines is necessary due to fragile laser or printer technology.

Name a method to recycle material from a build that did not form the part.

Name a method to recycle material from a build that did not form the part.

Flashcards are hidden until you start studying

Study Notes

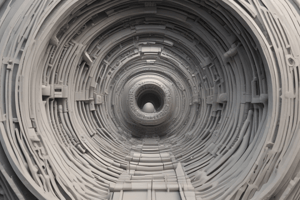

Generalized AM Process Chain

- Consists of eight key steps: Conceptualization and CAD, Conversion to STL, Transfer and Manipulation of STL File on AM Machine, Machine Setup, Build, Part Removal and Cleanup, Post-processing, and Application.

- Can be applied in various areas including areas that don’t involve conventional CAD modeling, like medical modeling, reverse engineering, and architectural modeling.

Eight Steps in AM

- STL (STereoLithography) is a simple way of describing a CAD model in terms of its geometry alone.

- STL files can be manipulated using specialized software tools.

- Machine setup parameters are critical for achieving acceptable final quality.

- The build process involves layer-based manufacturing controlled by a computer.

- Support structures may be required to prevent parts from collapsing or warping during the build process.

- Post-processing may involve abrasive finishing, coatings, or other application-specific tasks.

- AM parts may have different mechanical properties than parts made using conventional manufacturing methods.

Metal Systems

- Use of substrates, energy density, weight, accuracy, and speed are important factors to consider.

Variations Across AM Machines

- Photopolymer based systems, powder based systems, molten material systems, and solid sheets are examples of AM machine variations.

Maintenance of Equipment

- AM machines can be sensitive to dirt, noise (both electrical and mechanical), and moisture.

Material Handling Issues

- Materials should be protected from moisture and excess light.

- Loading material is often done offline using software systems.

- Recycling of material from failed builds can be effective.

Design for AM

- Consider part orientation, removal of supports, hollowing out parts, inclusion of undercuts and other manufacturing constraining features, interlocking features, reduction of part count in an assembly, and identification markings/numbering.

Interlocking Features

- Interlocking features can be used to create complex shapes.

Future Considerations

- Some AM technologies are moving towards thicker layers or processing regions rather than layers.

- Color and other forms of multiple material systems are becoming more common.

- Hybrid technologies that combine additive, subtractive, and robotic handling are being developed.

- Software is being optimized for AM processing.

- Standardized software processes based around AM are needed.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.