Podcast

Questions and Answers

What is the primary function of the combustor in a gas turbine system?

What is the primary function of the combustor in a gas turbine system?

- To expand hot gas

- To add fuel to the compressed air and ignite (correct)

- To compress air

- To convert mechanical energy into electrical energy

What is the ideal thermodynamic cycle for a gas turbine?

What is the ideal thermodynamic cycle for a gas turbine?

- Carnot Cycle

- Rankine Cycle

- Brayton Cycle (correct)

- Otto Cycle

What is the main advantage of a combined cycle gas turbine system?

What is the main advantage of a combined cycle gas turbine system?

- Higher power-to-weight ratio

- Larger size

- Lower emissions

- Higher thermal efficiency (correct)

What is the main challenge in designing gas turbines for aircraft applications?

What is the main challenge in designing gas turbines for aircraft applications?

What is the primary application of cogeneration gas turbine systems?

What is the primary application of cogeneration gas turbine systems?

What is the main limitation of gas turbines in terms of maintenance?

What is the main limitation of gas turbines in terms of maintenance?

In a gas turbine system, what component converts mechanical energy into electrical energy?

In a gas turbine system, what component converts mechanical energy into electrical energy?

What is a characteristic of gas turbines that makes them suitable for marine applications?

What is a characteristic of gas turbines that makes them suitable for marine applications?

Flashcards are hidden until you start studying

Study Notes

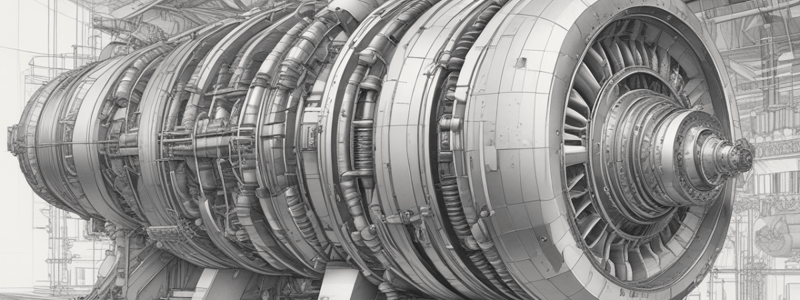

Components of a Gas Turbine System

- Compressor: compresses air, increasing its temperature and pressure

- Combustor (or Combustion Chamber): fuel is added to the compressed air, igniting and producing hot gas

- Turbine: hot gas from the combustor expands through the turbine, generating power

- Generator: converts mechanical energy from the turbine into electrical energy

Principles of Operation

- Brayton Cycle: the ideal thermodynamic cycle for a gas turbine, consisting of:

- Isentropic compression

- Isobaric heat addition

- Isentropic expansion

- Isobaric heat rejection

Types of Gas Turbine Systems

- Simple Cycle: a basic gas turbine system, using a single turbine and compressor

- Combined Cycle: a system that uses both a gas turbine and a steam turbine to increase efficiency

- Cogeneration: a system that generates both electricity and heat (or steam)

Applications

- Power Generation: gas turbines are used in power plants to generate electricity

- Aircraft: gas turbines are used as jet engines in aircraft

- Industrial: gas turbines are used in industrial processes, such as oil refining and natural gas processing

- Marine: gas turbines are used in ship propulsion systems

Advantages

- High Power-to-Weight Ratio: gas turbines are compact and lightweight, making them suitable for mobile applications

- High Efficiency: gas turbines can achieve high thermal efficiency, especially in combined cycle systems

- Low Emissions: gas turbines can be designed to produce low emissions, making them a relatively clean source of power

Challenges and Limitations

- High Temperature: gas turbines operate at extremely high temperatures, requiring specialized materials and cooling systems

- Noise and Vibration: gas turbines can produce significant noise and vibration, requiring soundproofing and vibration isolation

- Maintenance: gas turbines require regular maintenance to ensure efficient and safe operation

Components of a Gas Turbine System

- Compressor: Raises air pressure and temperature to prepare it for combustion.

- Combustor: Mixes fuel with compressed air, igniting it to create high-temperature gas.

- Turbine: Expands hot gas produced in the combustor to generate mechanical power.

- Generator: Transforms the mechanical energy from the turbine into electrical energy.

Principles of Operation

- Brayton Cycle: The underlying thermodynamic cycle consists of:

- Isentropic compression (air is compressed without heat transfer)

- Isobaric heat addition (constant pressure combustion)

- Isentropic expansion (gas expands and does work on the turbine)

- Isobaric heat rejection (excess heat is expelled)

Types of Gas Turbine Systems

- Simple Cycle: Features a single turbine and compressor for direct power generation.

- Combined Cycle: Integrates both gas and steam turbines, improving overall efficiency.

- Cogeneration: Produces electricity alongside heat or steam, utilizing waste energy effectively.

Applications

- Power Generation: Fundamental technology in power plants for electricity generation.

- Aircraft: Jet engines utilize gas turbines for propulsion in commercial and military aircraft.

- Industrial Processes: Essential in sectors like oil refining and gas processing for energy.

- Marine: Employed in propulsion systems for ships and marine vessels.

Advantages

- High Power-to-Weight Ratio: Enables mobile applications, ideal for aircraft and ships.

- High Efficiency: Maximizes energy output, particularly in combined cycle setups.

- Low Emissions: Design advancements allow for cleaner operation and reduced environmental impact.

Challenges and Limitations

- High Temperature Operation: Requires advanced materials and cooling techniques to maintain turbine integrity.

- Noise and Vibration: Generates significant noise; soundproofing measures are essential.

- Maintenance Needs: Regular maintenance is crucial for optimal performance and safety assurance.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.